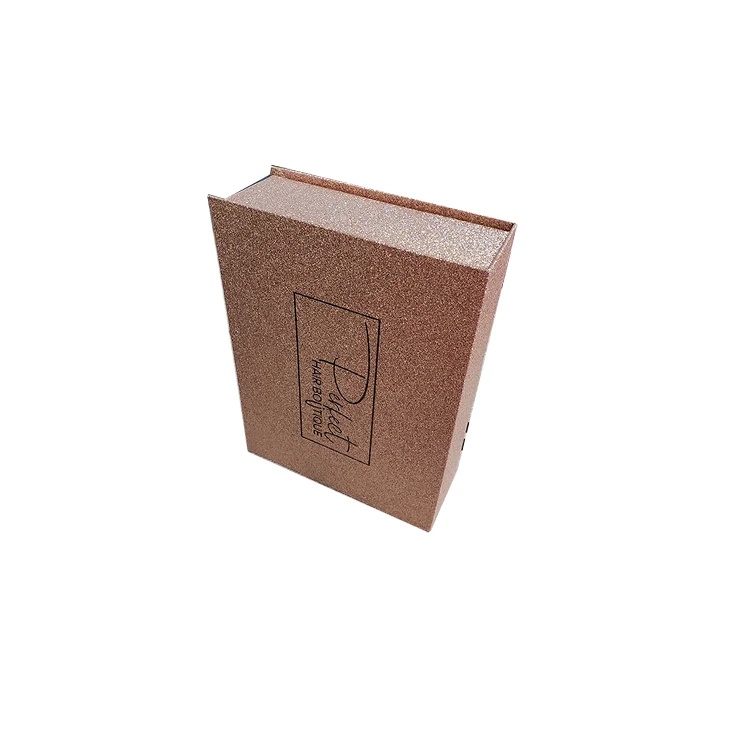

صُمم صندوق التغليف هذا خصيصًا لمنتجات إطالة الشعر المستعار، حيث يجمع بين تقنية الإغلاق المغناطيسي وحرفية المواد الصديقة للبيئة لابتكار حل تغليف راقي يتسم بالجمالية والوظيفية في آن واحد. يعتمد هيكل الصندوق على هيكل هندسي حاد، مع سطح ورقي لامع ونظام فتح وإغلاق مغناطيسي لضمان سلامة النقل وسهولة الاستخدام.

الوصف

دليل منتج علبة ورق تمديد الشعر المستعار المغناطيسي اللامع الورقي اللامع

1. صناديق الإغلاق المغناطيسي النظام

- تصميم الدوائر المغناطيسية الدقيقة: اعتماد مغناطيس دائم NdFeB من الدرجة N52، مع دائرة مغناطيسية متعددة الأقطاب ذات ترتيب حلقي متعدد الأقطاب، لتحقيق قوة شفط من نقطة واحدة 12N، وفتح وإغلاق سلسين، وإحكام إغلاق IP54.

- تحسين التشغيل بيد واحدة: من خلال زاوية التموضع المخروطية بزاوية 60 درجة والتصميم التعاوني للإبزيم المرن، تتم محاذاة النقطة المغناطيسية تلقائيًا، ويمكن فتحها بالتدوير 15 درجة. خطأ الفتح والإغلاق بيد واحدة أقل من 0.3 مم.

- مضاد للفتح العرضي: تتم مطابقة النقطة المغناطيسية مع هيكل عضة فتحة البطاقة، ويلزم عزم دوران 5N للفصل. يجتاز اختبار اهتزاز النقل معيار ISTA 3A.

2. هيكل الصندوق

- نوع مربع التحسين الهندسي: استنادًا إلى تحليل وحساب العناصر المحدودة، يعتمد تصميم خط الطي سداسي السطوح، مع خطأ في الحافة يبلغ ± 0.5 مم وقوة ضغط تبلغ 800 كجم/م².

- نظام العض الدقيق: الغطاء والجزء السفلي الصندوق اعتماد هيكل متداخلة متداخلة 2 مم، مع أضلاع تقوية صفائح فولاذية مغناطيسية 0.5 مم، تم تحسين الأداء العام المضاد للسقوط بواسطة 40%.

3. مواد صديقة للبيئة

- ورق مقوى معتمد من FSC: إنها تعتمد على ركيزة لوح رمادي مزدوج بسماكة 1.5 مم، مع طبقة فلاش 120 جم/م² على السطح، وقد حصلت على شهادة SGS للمعادن الثقيلة وشهادة REACH البيئية.

- شريط مضاد للكهرباء الساكنة: تتم معالجة الشريط الأسود بطبقة من الكربون النانوي، مع مقاومة سطحية تبلغ ≤10 ⁶Ω وزمن اضمحلال ثابت أقل من 0.5 ثانية، مما يضمن عدم حدوث أي تشوه أثناء النقل.