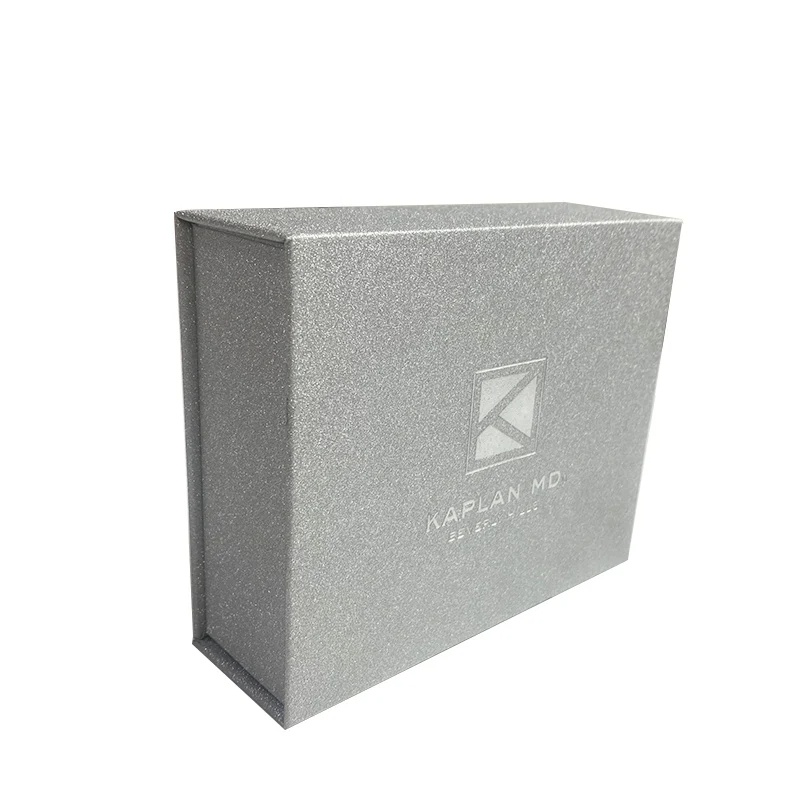

Large Silver Glitter Magnetic Closure Gift Box for Promotion

As a magnetic closure technology, which is easy to operate and closes precisely. There is no need for traditional buckles, and the opening and closing experience is smoother and more elegant. The surface is covered with Glitter Paper, which presents a delicate glittering effect and produces dynamic luster under the refraction of light, which enhances the visual grade of the product and meets the personalized needs of the brand.

תיאור

Product Description of Large Silver Sequin Magnetic Buckle Promotional Gift Box

1. Magnetic Closure System: Precision and Elegance

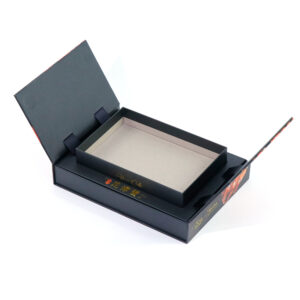

The lid adopts strong magnetic adsorption technology, and the magnetic strip embedded design is used to achieve closure without jamming. The magnetic force is precisely positioned when closed, and the contact surface is covered with a flexible sound-absorbing velvet layer to eliminate the collision sound of traditional buckles. The opening and closing action is as smooth as silk, and the operation can be completed with one hand, which meets the dual needs of luxury packaging for ritual and convenience.

2. Minimalist geometric structure: balance of rigidity and beauty

The box body adopts hardboard composite structure, and the edges and corners are processed by 45° chamfering process, with tough lines but soft. The internal configuration of the annular step groove support frame can bear 3kg without deformation, which is suitable for the protection needs of fragile high-end gifts such as jewelry and watches. The hexahedron compression test meets the international transportation standard ISTA-3A to ensure long-distance transportation safety.

3. Dynamic optical surface: Glitter Paper process

The surface uses stardust-grade glitter paper imported from Germany, and achieves 270° light refraction coverage through nano-level glitter directional arrangement technology. It presents the texture of galaxy gravel statically and the shimmering effect dynamically. The light reflectivity is increased by 60% compared with the traditional hot stamping process, and it can form a unique brand visual memory point under the lighting of commercial windows.

4. Precision manufacturing system: millimeter-level quality control standard

The whole process adopts Japan Mitsubishi laser cutting system to achieve 0.1mm-level seam accuracy. The box body undergoes triple quality inspection: UV flaw detection to detect micro cracks, three-dimensional measuring instrument to verify deformation, and colorimeter to control △E≤1.5, to ensure that each product meets the appearance standard of art.

5. Lasting visual communication: ink curing technology

The text printing adopts Swiss environmentally friendly UV curing ink, which has passed 72 hours of salt spray test and 5000 times of friction test, and the color fastness reaches level 8. Supports Pantone spot color + 4-color overlay printing, complex logos can achieve 0.2mm line width reproduction, meeting the needs of luxury anti-counterfeiting micro-printing.

6. Restrained aesthetic design: functional minimalism

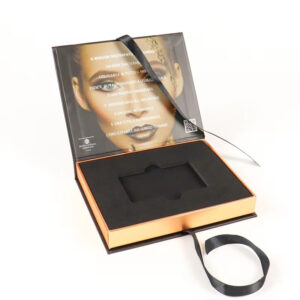

Implement Bauhaus design concept and eliminate all redundant decorative parts. Replace traditional hardware with magnetic opening and closing structure, and use the reflective properties of the material itself to create a visual focus. The inner cavity adopts a detachable honeycomb partition system, which not only meets the storage needs of multiple categories, but also maintains the purity of the appearance.

7. In-depth customization service: brand-specific solution

- Surface technology: support cold stamping/hot pressing/laser engraving three-mode logo technology, hot stamping accuracy ±0.3mm

- Spatial reconstruction: can provide EVA flocking/blister/PP grid inner support, suitable for special-shaped product fixation

- Agile response: relying on modular mold system, complete size adjustment proofing within 72 hours

8. Smart manufacturing service guarantee: flexible production system

The manufacturer holds FSC forest certification and ISO14001 environmental system certification, and has 16 years of professional packaging production experience. Provide small batch customization service with a minimum order of 500 pieces, supporting 3D structure drawing pre-examination, material sample book delivery, drop test video feedback and other full-process services, which is 40% lower than the industry average trial and error cost.