Custom Makeup Beauty Blender Sponge Packaging Boxes Factory

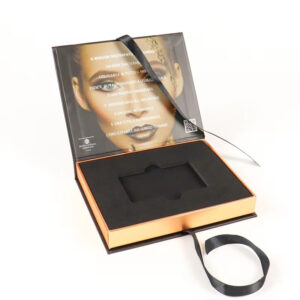

The cardboard box design uses 350g white card as the whole box, which can reduce costs while also enabling flat shipments, greatly reducing transportation costs. The window with film can better display the product, and the inner lining is designed with paper cards, which is convenient for fixing the product and more environmentally friendly.

תיאור

Customized makeup egg sponge packaging box

1. High-quality materials and transparent display design

This product is made of 350g high-weight white cardboard. The paper is thick and crisp, with both pressure resistance and aesthetics. The front of the box is innovatively designed with window-opening film technology, and high-transparency PVC or PET film is used, which can not only clearly display the shape and color of the internal makeup egg, but also play a role in dust and moisture prevention. The edge of the window area adopts a precision cutting process to ensure a tight fit without burrs, enhance the attractiveness of product display, and facilitate customers to intuitively select.

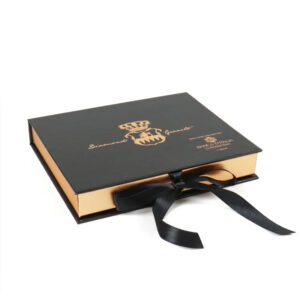

2. High-end printing technology empowers brand image

The box surface printing adopts imported Heidelberg printing machine, equipped with a four-color fully automatic color management system, accurately restores the brand LOGO, pattern and gradient color. The printing ink has passed the SGS environmental protection certification, with rich color and no irritating odor. With the UV local glazing process, it realizes the combination of mirror gloss and matte texture, giving the packaging box a high-level visual layering. The color difference control accuracy reaches ΔE≤1.5, ensuring the consistency of batch production and helping the brand’s high-end positioning.

3. Environmentally friendly lining and efficient structural design

The lining adopts environmentally friendly paper card die-cutting technology, and forms a honeycomb support structure through precise folding, which tightly fixes the beauty egg to avoid shaking during transportation. The paper card uses FSC-certified raw pulp paperboard, which can be completely recycled and degraded, replacing the traditional foam lining, and complies with the EU REACH environmental protection standards. The overall card box flat design is adopted, which is a single-piece folding form when not assembled, greatly reducing the storage and transportation space occupation, and reducing logistics costs by more than 30%. After receiving the goods, customers can quickly assemble them by hand without the assistance of glue, which is convenient to operate.

4. Source factory guarantee and full-link service

Relying on 16 years of packaging manufacturing experience, the factory is equipped with fully automatic die-cutting machines, box-gluing machines and quality inspection lines, achieving a daily production capacity of 100,000+ standard boxes, and the delivery cycle is compressed to 7-10 working days. The supply chain integrates upstream resources such as paper, film, and ink, with costs 15%-20% lower than the market average, and supports flexible production with a minimum order of 1,000 pieces. Passed ISO9001 quality management system certification, the entire quality inspection covers the entry of raw materials to the shipment of finished products, and the defect rate is controlled within 0.3%.

5. Integrated foreign trade service solution

The professional foreign trade team provides one-stop cross-border services, covering design proofing, export customs declaration, international logistics and after-sales support. Supports multi-language business docking in English, Spanish, Arabic, etc., and is familiar with market access standards in Europe, the United States, the Middle East, and Southeast Asia (such as FDA, CE certification). Can assist customers in completing brand VI implantation, customized anti-counterfeiting labels, and cross-border e-commerce platform compliance packaging optimization, helping the brand’s global layout.

Summary of core advantages

- Cost optimization: Flat structure + direct supply from the source, reducing overall costs by 25%

- Environmental compliance: Biodegradable materials throughout the entire process, passed BSCI and Sedex social responsibility audits

- Quality assurance: Heidelberg printing + automated production line, color accuracy reaches Pantone 99% matching

- Agile service: 3D design drafts are provided within 48 hours, and proofing is completed within 72 hours