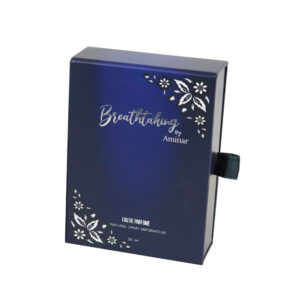

Il design di questa scatola con coperchio magnetico consente agli utenti di accedere rapidamente al flacone mantenendo l'integrità della confezione, tenendo conto della praticità e del rituale, con linee pulite, in linea con l'estetica moderna e adatte a una varietà di scenari espositivi. Il corpo della scatola utilizza una tonalità nera pura per trasmettere la professionalità del marchio e l'affidabilità del prodotto, che si adatta al posizionamento naturale e di fascia alta del mercato dell'olio di CBD ed è facile da differenziare dai prodotti concorrenti.

Descrizione

Custom olio di canapa chiusura magnetica scatole rigide Cina all'ingrosso

1. Design innovativo della scatola con chiusura magnetica, che tiene conto della praticità e del senso del rituale.

Questo scatola di imballaggio adotta struttura di chiusura magneticaGrazie alla collaborazione tra il foglio di aspirazione della chiusura magnetica ad alta precisione e il foglio di guida del coperchio magnetico, può essere facilmente aperto e chiuso con una sola mano. La forza magnetica è stata scientificamente testata per garantire un rapido accesso al corpo della bottiglia e mantenere l'integrità della confezione quando è chiusa, evitando aperture accidentali durante il trasporto o lo stoccaggio. Il design del coperchio a ribalta del corpo della scatola si adatta all'ergonomia, si apre e si chiude in modo fluido senza incepparsi, dando agli utenti un senso di rituale al momento del disimballaggio e soddisfacendo al contempo le esigenze di praticità dell'uso ad alta frequenza.

2. Design estetico moderno, adatto a più scene

L'imballaggio utilizza linee rette e ordinate come linguaggio di base, abbandona le decorazioni ridondanti e presenta una semplice bellezza geometrica. Il rapporto tra i tipi di scatola è stato ottimizzato dalla sezione dorata, che si adatta a scenari espositivi diversificati come gli scaffali dei supermercati, i banchi dei marchi e le piattaforme di e-commerce. La superficie adotta una tonalità di nero puro opaco, con il logo del marchio stampato a caldo/argento artigianale, creando un'immagine di calma e atmosfera che si adatta al posizionamento di mercato naturale e di fascia alta dell'olio di CBD e costituisce una differenza netta rispetto ai prodotti della concorrenza.

3. Struttura rinforzata in carta patinata, protezione a lungo termine del contenuto.

Il corpo della scatola utilizza Supporto in carta patinata da 450 gLa resistenza alla compressione è aumentata di 30%, in grado di resistere agli urti del trasporto e alla pressione di impilamento. L'interno è combinato con una fodera in EVA ad alta densità, fustellato con precisione Il corpo della bottiglia è fissato saldamente per evitare l'usura o le perdite causate dagli scuotimenti. Ai quattro angoli del corpo della scatola sono state aggiunte delle protezioni angolari anticollisione per migliorare ulteriormente la resistenza agli urti e garantire la sicurezza dello stoccaggio a lungo termine.

4. Qualità Seiko, i dettagli dimostrano l'ingegno

Adottare stampi di alta precisione e tecnologia di fustellatura completamente automaticaLe cuciture del corpo della scatola sono lisce e prive di bave, mentre l'ammortizzazione dell'apertura e della chiusura dello sportello è moderata e garantisce un'esperienza d'uso fluida. La stampa della superficie utilizza la tecnologia di stampa offset in quadricromia + vernice UV locale; il disegno è chiaro e delicato, la saturazione del colore è elevata, ed è resistente all'usura e ai graffi. Il giunto di rivestimento adotta la tecnologia di laminazione a ultrasuoni per evitare la contaminazione della colla e soddisfare gli standard di sicurezza degli imballaggi alimentari.

5. Servizio di personalizzazione full-dimensionale, per potenziare il marketing del marchio.

Supporta le seguenti soluzioni di personalizzazione flessibile:

- Dimensioni e tipo di scatola: Adattamento alle specifiche delle bottiglie di olio di sesamo da 50ml-500ml e sviluppo di tipi di scatole innovative come quelle a cassetto e a libro;

- Contenuto della stampa: Supporta la stampa a pagina intera di logo del marchio, slogan, codice anticontraffazione, ecc. e può aggiungere l'anticontraffazione laser, il codice QR a dati variabili e altri processi;

- Struttura del rivestimento interno: Fornisce opzioni di EVA, spugna, floccaggio e altri materiali, supporta il design del compartimento divisorio e soddisfa le esigenze di combinazione di più bottiglie. imballaggio;

- Aggiornamento magnetico: Fibbia magnetica forte (1,0 cm) o fibbia magnetica ordinaria (1,4 cm/1,8 cm) per adattarsi alle diverse esigenze di carico.

6. Garanzia di una catena di fornitura matura, consegna efficiente senza preoccupazioni

Affidarsi a 16 anni di esperienza professionale nella produzione di imballaggiLa fabbrica è dotata di una linea di produzione completamente automatica e di un sistema di controllo della qualità ISO per collegare in modo efficiente l'intera catena, dalla progettazione alla produzione di massa.

- Garanzia di controllo qualità: Le materie prime sono certificate SGS e nel processo di produzione vengono implementati 6 processi di ispezione della qualità, con un tasso di difettosità inferiore a 0,3%;

- Risposta rapida: Supporto di 2-3 giorni di ciclo di prova, produzione di una quantità minima di ordine di 500 pezzi;

- Tecnologia ad alta difficoltà: Bravi in processi complessi come scatole di forma speciale, strutture di aspirazione magnetica e materiali degradabili ecologici, aiutano i marchi a superare la concorrenza omogenea.

Scenari di applicazione

- Marchio di olio di sesamo di alta gamma: In linea con il tono dei prodotti naturali e biologici, valorizzare lo spazio premium del terminal;

- Mercato della personalizzazione dei regali: Rafforzare l'unicità della vacanza confezione regaloe soluzioni di personalizzazione aziendale attraverso un design esclusivo;

- Commercio elettronico transfrontaliero: Soddisfare gli standard di trasporto internazionali e ridurre i rischi di perdite logistiche transfrontaliere.