Questa scatola adotta una forma triangolare unica, che rompe la forma convenzionale della scatola quadrata. La scatola superiore e inferiore è facile da aprire e chiudere, migliorando l'esperienza dell'unboxing.

Descrizione

Scatole rigide d'imballaggio triangolari personalizzate all'ingrosso con logo

1. Design unico, che sovverte l'esperienza visiva tradizionale

Questo imballaggio adotta un'innovativa struttura triangolare tridimensionale, superando i limiti delle tradizionali scatole quadrate e utilizzando l'estetica geometrica per migliorare il riconoscimento del marchio e l'impatto visivo.

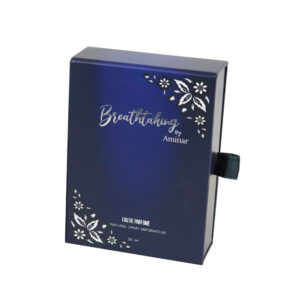

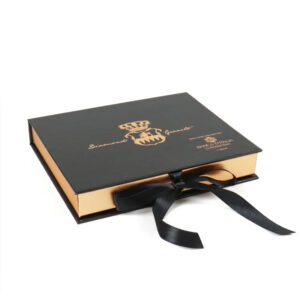

2. Design estetico minimalista, per rafforzare la memoria del marchio

La confezione si basa sui classici colori bianco e nero. L'intero corpo è realizzato in puro cartone nero con un montaggio monofacciale da 1200 g in cartoncino nero e grigio. Ha un tocco delicato e una consistenza spessa, che mantiene perfettamente la forma tridimensionale della scatola rigida triangolare. La superficie della scatola è impreziosita dal testo o dalla grafica bianca del marchio, formando un forte contrasto visivo, semplice e d'atmosfera, che trasmette il tono di alta gamma del marchio. La parte del logo adotta la tecnologia di stampa a caldo per migliorare la texture attraverso la lucentezza metallica. Può anche essere personalizzata su richiesta per i processi UV, goffratura, opaco e altri processi per soddisfare le diverse esigenze di espressione del marchio.

3. Materiali e lavorazioni ecocompatibili, che tengano conto sia della qualità che della sostenibilità.

- Materiale principale: Cartone nero ecologico, con valore PH neutro, riciclabile 100% e in linea con gli standard ambientali internazionali; rivestimento in cartone grigio ad alta densità da 1200 g per garantire la robustezza e la durata della scatola.

- Artigianato: La superficie può essere rivestita a scelta con film/sottofilm luminosi, goffrati, ecc. per migliorare le prestazioni impermeabili e antivegetative; la stampa a caldo, i processi UV e altri utilizzano tutti inchiostri non tossici e rispettosi dell'ambiente e superano la certificazione SGS.

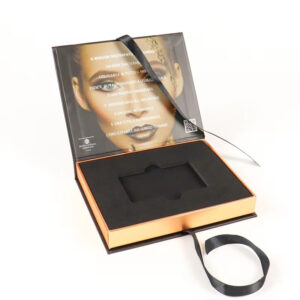

4. Soluzione di supporto interno personalizzata, adattamento preciso alla protezione del prodotto

In base alle caratteristiche dei prodotti dei clienti, forniamo una varietà di materiali di supporto interno ecocompatibili, come spugna, EVA, cotone perlato, ecc. e realizziamo un adattamento perfetto alla forma del prodotto grazie a un'apertura precisa dello stampo per evitare scosse di trasporto. Il supporto interno può essere progettato come struttura sezionale, tipo blister o struttura di rivestimento morbida, adatta a diverse categorie come gioielli, accessori elettronici e strumenti di precisione.

5. Ampi campi di applicazione e potenziamento del marchio

Questo triangolo scatola di imballaggio è progettato per prodotti ad alto valore aggiunto, che coprono i seguenti settori:

- Accessori moda: come gioielli di lusso leggeri e gioielli di design, evidenziando il tono artistico.

- Giocattoli di tendenzacome le scatole cieche e le figure, attirando gruppi di consumatori giovani grazie a forme uniche.

- Cancelleria di alta gammaCome le penne in edizione limitata e i taccuini d'arte, che arricchiscono gli attributi del regalo.

- Cibo/tè: può essere abbinato alla tecnologia di stampa a caldo e alla fodera antiumidità, adatta alle scatole regalo per le vacanze.

6. Garanzia di forza dell'impresa leader, supporto di servizio full-link

In qualità di azienda leader nel settore della stampa e imballaggio Abbiamo servito più di 2.500 marchi nazionali ed esteri e offriamo i seguenti vantaggi fondamentali:

- Produzione flessibile: supporto 500 pezzi di ordine minimo, capacità di produzione giornaliera di milioni, per soddisfare le esigenze di ordini urgenti.

- Servizio completo di processoDall'ottimizzazione della bozza di design (supporto del formato AI/CDR/AI), alla conferma delle bozze fino alla produzione in serie, 7-14 giorni di consegna estremamente rapida.

- Garanzia post-vendita: Forniamo servizi di risarcimento danni, tracciamento logistico e gestione del magazzino, e il tempo di risposta post-vendita è inferiore a 24 ore.

Parametri tecnici

| Progetto | Specifiche tecniche |

|---|---|

| Materiale | Cartone nero ecologico + cartoncino grigio nero monofacciale da 1200 g |

| Processo | Stampa a caldo su lamina / Spot UV / goffratura / laminazione (opzionale) |

| Dimensione | Supporto 1-100cm personalizzazione |

| Quantità minima ordinabile | 500 pezzi |

| Ciclo di consegna | 7-14 giorni (adattati in base alla complessità del processo) |

Processo di cooperazione

- Richiesta di conferma: Fornire le dimensioni del prodotto, la bozza di progetto e i requisiti di processo.

- Revisione della prova di stampa: Fornire scatole campione fisiche entro 3-5 giorni lavorativi.

- Produzione di massa: Avviare la produzione dopo il pagamento anticipato e monitorare l'ispezione della qualità durante l'intero processo.

- Consegna logistica: Supportare il trasporto globale e fornire soluzioni di imballaggio antiurto.