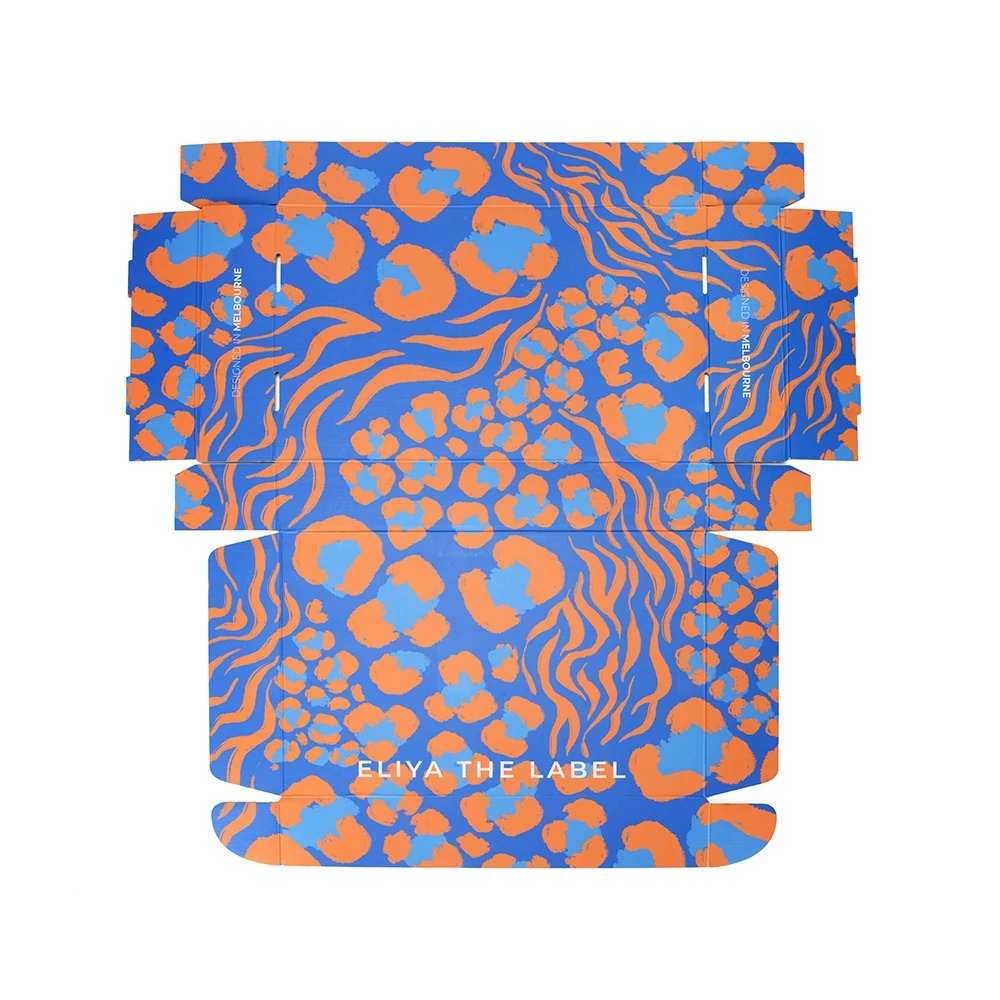

Questa scatola mailer per il confezionamento di prodotti per la cura della pelle con crema per il viso utilizza il blu e l'arancione come schema di colori principale. Il forte contrasto può attirare rapidamente l'attenzione dei consumatori. Il design irregolare del modello può dare al marchio un'etichetta visiva all'avanguardia e personalizzata.

Descrizione

1. Contrasto blu e arancione e fusione di motivi animali

Utilizzando una combinazione di colori complementari blu e arancione (distanza di tinta di 180°), con un blu cobalto altamente saturo e un arancione vibrante per creare un impatto visivo, con texture astratte di animali zebrati o ghepardi, si forma una tensione visiva dinamica sulla superficie del scatola di imballaggio. L'immagine principale è tagliata e disposta con blocchi di colore irregolari e il senso di luce tridimensionale è presentato attraverso la sovrapposizione di colori sfumati e la tecnologia di rivestimento UV locale. Ad esempio, la parte anteriore del corpo della scatola utilizza motivi blu a base arancione per simulare la luce e l'ombra della giungla al tramonto, mentre la parte laterale utilizza motivi arancioni a base blu per fare da eco, trasmettendo la collisione tra la bellezza selvaggia e la moda urbana.

2. Design asimmetrico a toppe e strisce

Rompendo la tradizionale composizione simmetrica, la superficie della scatola è sfalsata da macchie strappate e strisce oblique, combinate con la tecnologia di goffratura per migliorare la stratificazione tattile. Ad esempio, la parte superiore del coperchio della scatola utilizza la tecnologia dell'incisione laser per presentare un incavo geometrico irregolare, rivelando la carta di supporto arancione fluorescente interna, formando un uovo di Pasqua visivo "nascosto". Il bordo è progettato con una struttura ondulata a coltello, che non solo richiama l'immagine dei segni degli artigli degli animali, ma aumenta anche la resistenza alla compressione del corpo della scatola.

3. LOGO ripetizione ad alta frequenza e presentazione tridimensionale

Il LOGO del marchio adotta un design a ripetizione ad alta frequenza: il logo principale è centrato sul coperchio della scatola con la tecnologia dell'argento caldo, il lato è disposto in una matrice di LOGO in miniatura (ripetuto ogni 10 cm) e il fondo è incorporato con un LOGO fluorescente invisibile (sviluppato sotto la luce ultravioletta) con un processo di colorazione a incasso. La superficie del logo combina le tecnologie di goffratura e di stampa in lamina d'oro, con uno spessore di 0,3 mm, un tocco tridimensionale e un aumento della resistenza all'usura di 40%.

4. Struttura della scatola mailer pieghevole

È stato adottato il design della scatola per aereo standard internazionale 0421, con dimensioni di 200×150×50 mm e uno spessore di soli 15 mm dopo la piegatura, che consente di risparmiare 85% di spazio di stoccaggio. I pannelli laterali del corpo della scatola sono realizzati in cartone ondulato a tre strati (struttura composita flauto B + flauto C), con una resistenza alla compressione verticale di 5000N/m², in grado di sopportare un trasporto impilato a 5 strati. L'apertura e la chiusura sono progettate con una guarnizione distruttiva a coltello e i consumatori possono aprirla strappando lungo la linea prestabilita, il che è sia antifurto che conveniente.

5. Carta ondulata leggera e ad alta resistenza

Sono state selezionate carta kraft di grado AA (quantità 220g/m²) e carta ondulata ad alta resistenza (indice di pressione anulare ≥8,5N-m/g). Grazie all'ottimizzazione della forma d'onda ondulata di tipo UV, le prestazioni di tamponamento sono migliorate di 30% rispetto a quelle tradizionali. scatole di carta. La superficie è ricoperta da una pellicola ecologica opaca, il coefficiente di attrito è pari a 0,6 e il tasso di perdita del trasporto può essere controllato entro 0,5%.

6. Stampa ad alta definizione e rivestimento funzionale

Viene utilizzata una macchina da stampa offset Heidelberg a cinque colori (risoluzione 4800 dpi) per ottenere una precisione di linea di 0,1 mm e una differenza blu-arancio ΔE≤1,5 (standard ISO 12647). L'area del modello chiave viene sovrapposta con la serigrafia locale, lo spessore dello strato di inchiostro è di 0,15 mm e la saturazione del colore è aumentata da 20%. Il rivestimento antibatterico viene stampato sulla parete interna del scatola (in conformità agli standard FDA 21CFR) per inibire efficacemente la crescita dei microrganismi.

7. 【Servizio personalizzato Risposta agile 】Processo di cooperazione

- Prove di progettazione: Fornire rendering 3D e prove fisiche entro 3 giorni lavorativi (supporto file AI adattamento automatico del tipo di scatola)

- Ciclo di produzione di massa: Ordine minimo di 500 pezzi, consegna in 5-7 giorni (supporto del servizio accelerato di 72 ore).

- Ottimizzazione dei costi: Grazie alla tecnologia di prestampa, è possibile mescolare 6 tipi di scatole nello stesso lotto e il tasso di utilizzo del cartone raggiunge 95%.