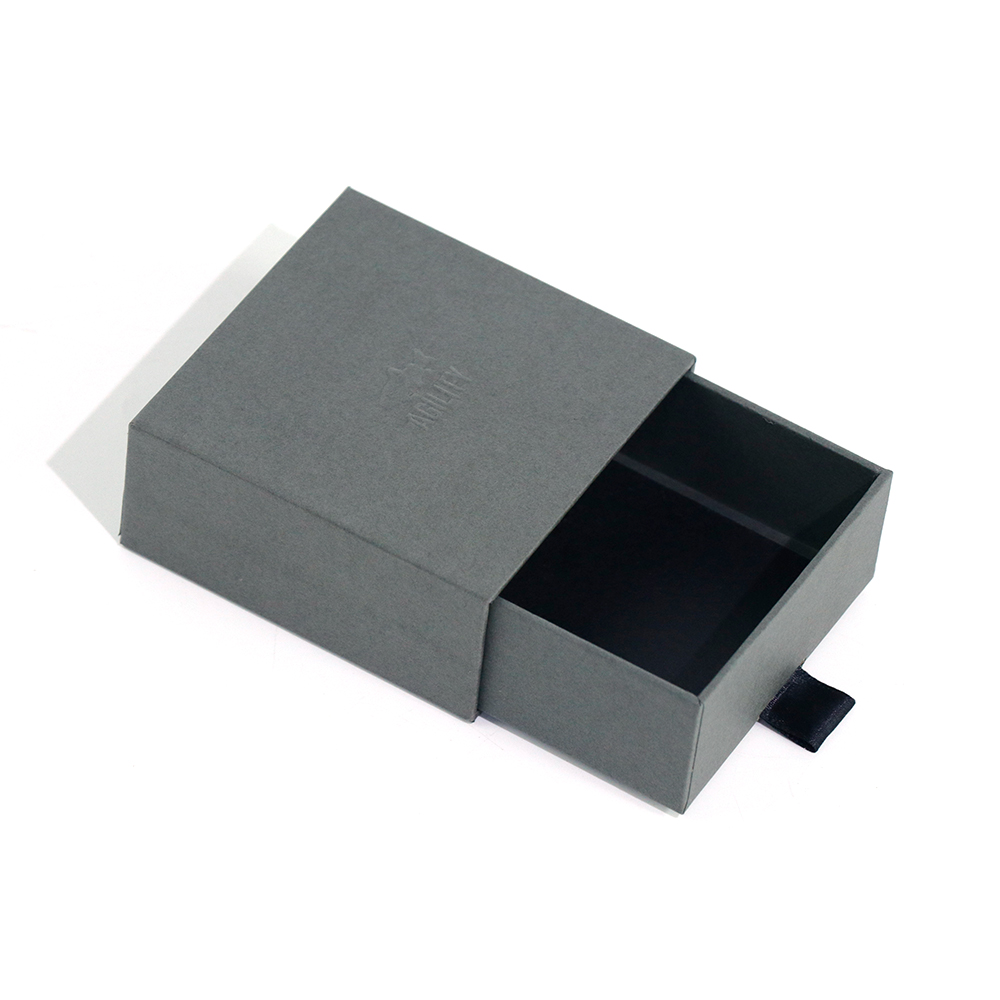

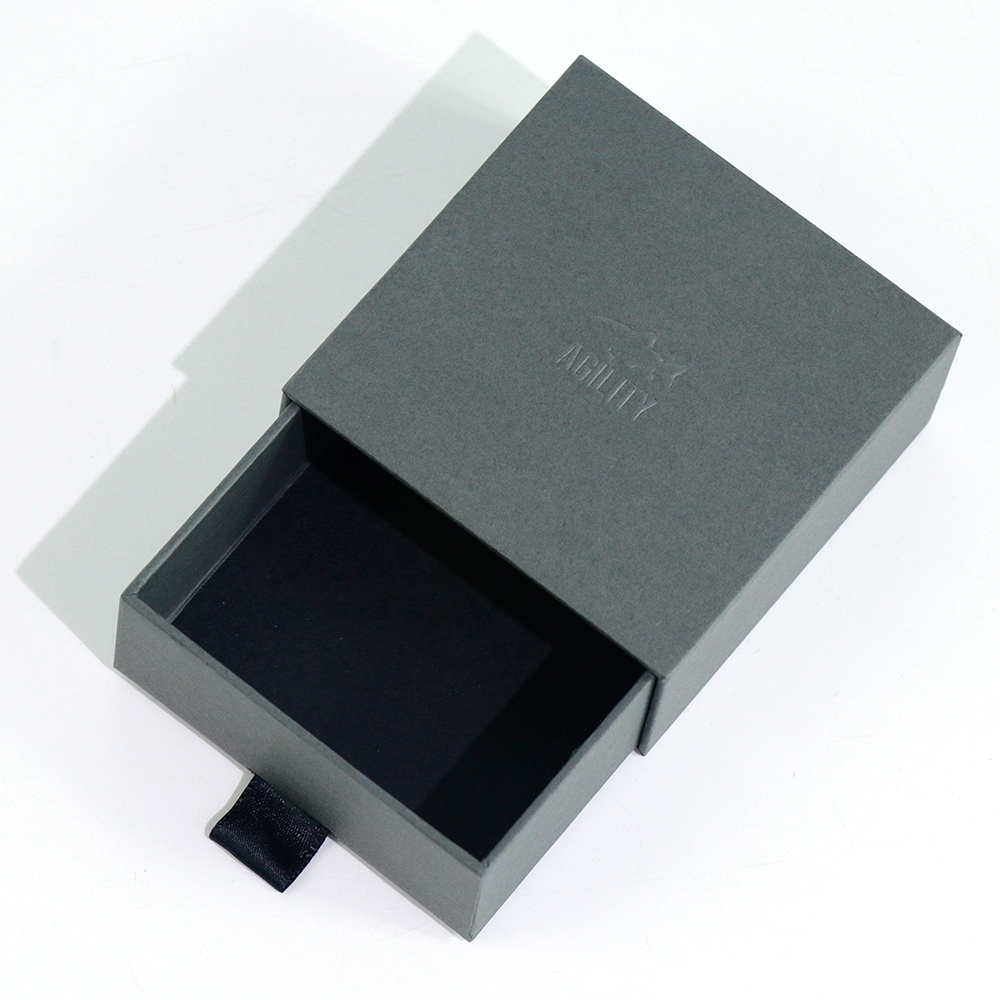

Lådan är utformad med en klassisk papperslåda, vilket kan ge kunderna en smidig upplevelse av att ta ut produkter. Den övergripande färgen är mörkgrå, vilket är lågmält, lugnt och modernt.

Beskrivning

1. Färgschema

Det mörkgrå ytterskalet matchas med en svart innerlåda för att skapa en visuell kontrast. Den mörkgrå huvudfärgen förmedlar en lågmäld och stadig affärsstruktur, och det svarta fodret förbättrar produktvisningseffekten genom färgkontrast, vilket kan fokusera synen så snart som box är öppnad.

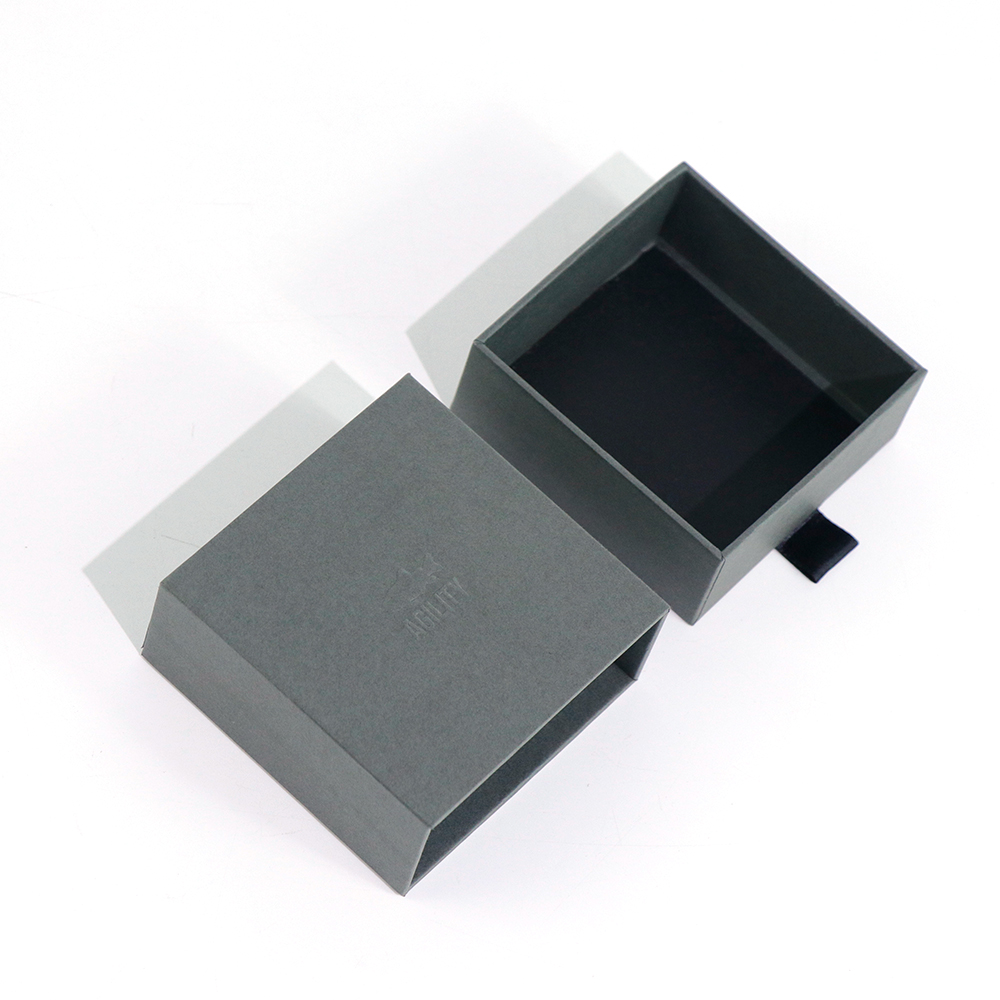

2. Struktur för papperslådor i lådor

Den klassiska papperslådor för lådor design bygger på industriell estetik. Lådstommen och lådan är anpassade till varandra med exakta toleranser. Styrskenesystemet förblir smidigt efter 5.000 öppnings- och stängningstester. Lådans hylsa har en rörformad vikstruktur för att förbättra tryckmotståndet, och lådans kant är rundad för att undvika repor.

3. Val av substrat

Det yttre skalet består av 1,5 mm helgrå kartong (FSC-certifierat miljövänligt material) och ytan är täckt med 120 g mörkgrått specialpapper med anti-fingeravtrycksbeläggning. Innerlådan består av 0,8 mm dubbel grå kartong + svart matt bestruket papper, med en böjhållfasthet på 15N-m²/g, och kan bära 5 kg utan deformation.

4. Tryckprocessen

Stödjer 12 processkombinationer inklusive varmstämpling guld/silver, partiell UV, prägling etc. LOGOTYPEN kan präglas med en tredimensionell reliefprocess, och metallfärgen har klarat säkerhetscertifieringen EU EN71-3.

5. Moduluppbyggt foder

Ger 6 materialalternativ inklusive EVA-skum, pärlbomull, flockning etc. Produktens konturdata genereras genom 3D-skanning och CNC-skärningsnoggrannheten når ± 0,2 mm, vilket är lämpligt för specialformade elektroniska produkter. Den flerskiktade partitionsdesignen kan fixa värden, tillbehören och instruktionerna samtidigt.

6. Seismisk prestanda

EVA-fodret har testats av ISTA 3A transport och kan buffra effekten av ett fall på 1,2 m. Skummets återfjädringshastighet är >90% och deformationshastigheten är <5% efter 100.000 kontinuerliga kompressioner.