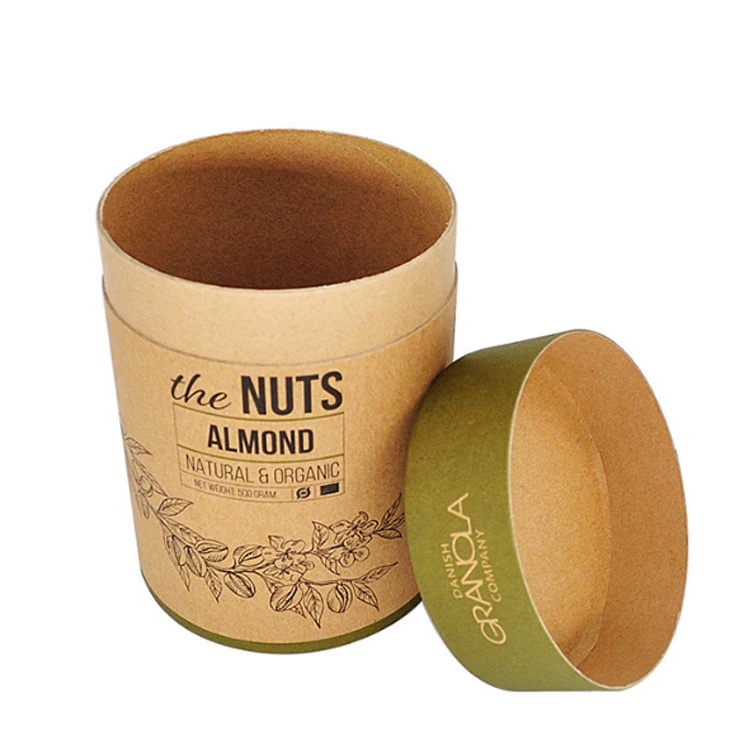

Med FSC-certifierat kraftpapper som bas och lamineringsteknik av livsmedelskvalitet skapar vi en biologiskt nedbrytbar och miljövänlig pappersrörsförpackning som är lämplig för granulatprodukter som te och kaffebönor. Det löstagbara locket kan öppnas och stängas med en hand, vilket förstärker varumärkets image.

Beskrivning

FSC ISO-certifierad livsmedelsgodkänd kraftpappersförpackning för te- och kaffecylindrar

1. Förpackning av papperstub

- 360° tredimensionell displayyta stärker varumärkesvisionen, och den lutande formen uppfyller kraven på fluiditet för granulerade livsmedel som mandel/teblad

- Mörkgrönt avtagbart lock som kan öppnas och stängas med en hand och dammtät försegling som uppfyller kraven för livsmedelsförvaring

- Cylinderdiametern är lämplig för automatiserade fyllningslinjer, och staplingsstabiliteten minskar transportskadorna med 30%

2. Dubbelt värde av kraftpappersmaterial av livsmedelskvalitet

- Den ursprungliga trämassafibern har klarat FDA-certifieringen för livsmedelskontakt och det finns ingen risk för migration av fluorescerande medel

- Det 3,2 mm tjocka kärnskiktet ger tryckhållfasthet (bär 5,5 kg utan deformation) och det yttre skiktets naturliga struktur framhäver tonen hos ekologiska produkter

- Nedbrytbarheten är över 98%, vilket är 65% mindre än koldioxidavtrycket för plast förpackning

3. Teknik för behandling av innerväggar på spegelnivå

- PE-lamineringsprocessen av livsmedelskvalitet bildar ett 0,03 mm barriärskikt för att förhindra att olja tränger in och aromer läcker ut

- 1200 mesh poleringsteknik uppnår Ra≤0,8μm finish för att undvika nötsmulor/te-rester

- Klarade SGS mikrobiella fästtest och uppfyller HACCP-systemets hygienstandarder

4. Fördelar med 6-färgs högupplöst utskriftssystem

- CMYK + spotfärg + varm stämplingsprocess återställer exakt strukturen på grenar och löv (minsta linjebredd 0,1 mm)

- UV-härdande bläck klarar EU EN71-3:s säkerhetstest för tungmetaller och smetar inte ut när det utsätts för vatten

- Intelligent positioneringssystem säkerställer att det inte blir några grader på kanterna av flerspråkig text

5. Tredubbelt skydd genom vattenbaserad lamineringsprocess

- 12 μm biaxiellt orienterad polypropylenfilm förbättrar ytans slitstyrka till 4H blyertshårdhet

- Fuktsäker prestanda bryter igenom 85%RH-fuktighetsmiljön, överföringshastighet för vattenånga <5g/m²-24h

- Temperaturbeständighetsområdet utökas till -18 ℃ ~ 120 ℃, lämpligt för fryst lagring och scenarier för återuppvärmning av mikrovågsugn

6. Tillverkningsfördelar med Shenzhen källfabrik

- Full-link-produktion (massatillverkning → upprullning → tryckning → laminering) förkortar leveranstiden till 7 arbetsdagar

- 50+ uppsättningar av formbibliotek stöder anpassning av Φ60-Φ300mm cylinderdiameter, och den minsta orderkvantiteten reduceras till 500st

- Angränsar till Yantian Port för att uppnå 7-dagars leverans av europeiska och amerikanska beställningar, vilket stöder DDP:s internationella handelstjänster

7. FSC+ISO dubbelcertifiering strategiskt värde

- FSC-COC-certifiering säkerställer att 100% av pappersmassan kommer från hållbart förvaltade skogar

- ISO15378 kvalitetsledningssystem på förpackningsnivå för läkemedel, spårbarhet för batcher på minuten

- Certifieringslogotypen kan tryckas på förpackningoch hjälper kunderna att komma in i exklusiva stormarknader som Whole Foods