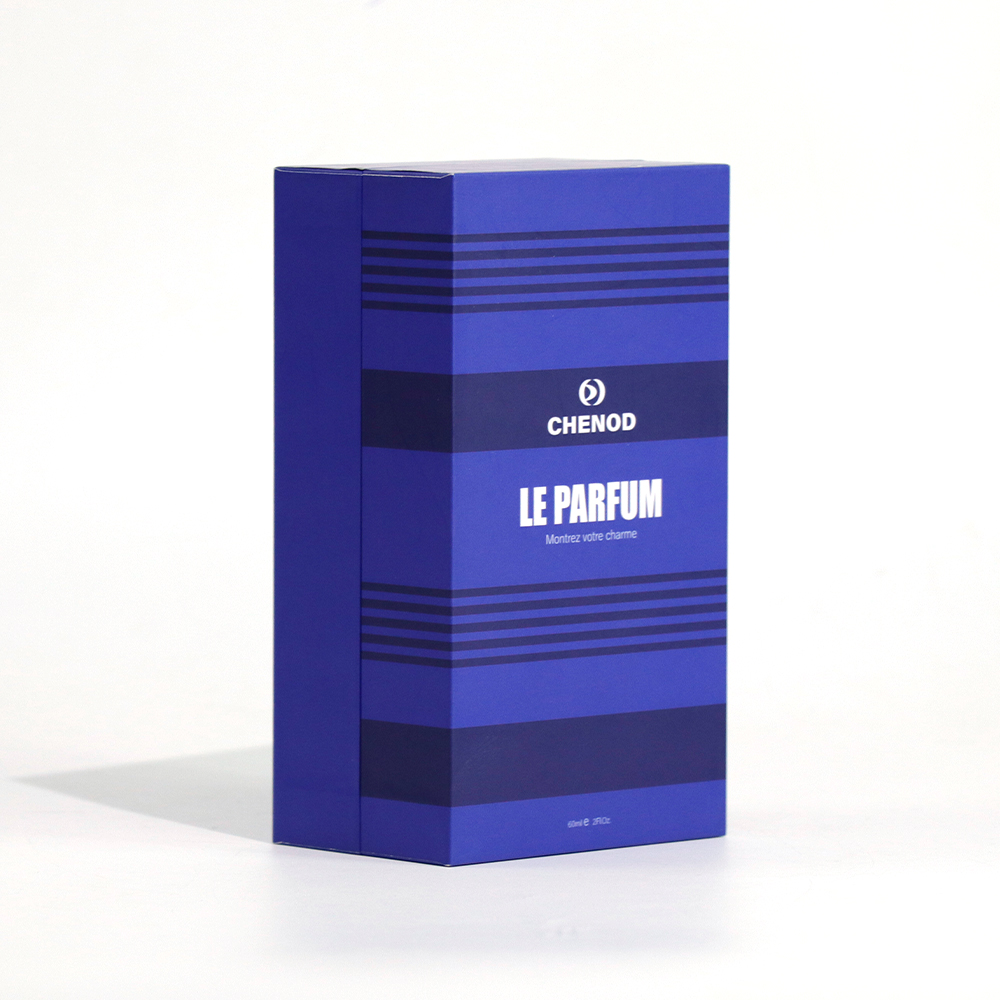

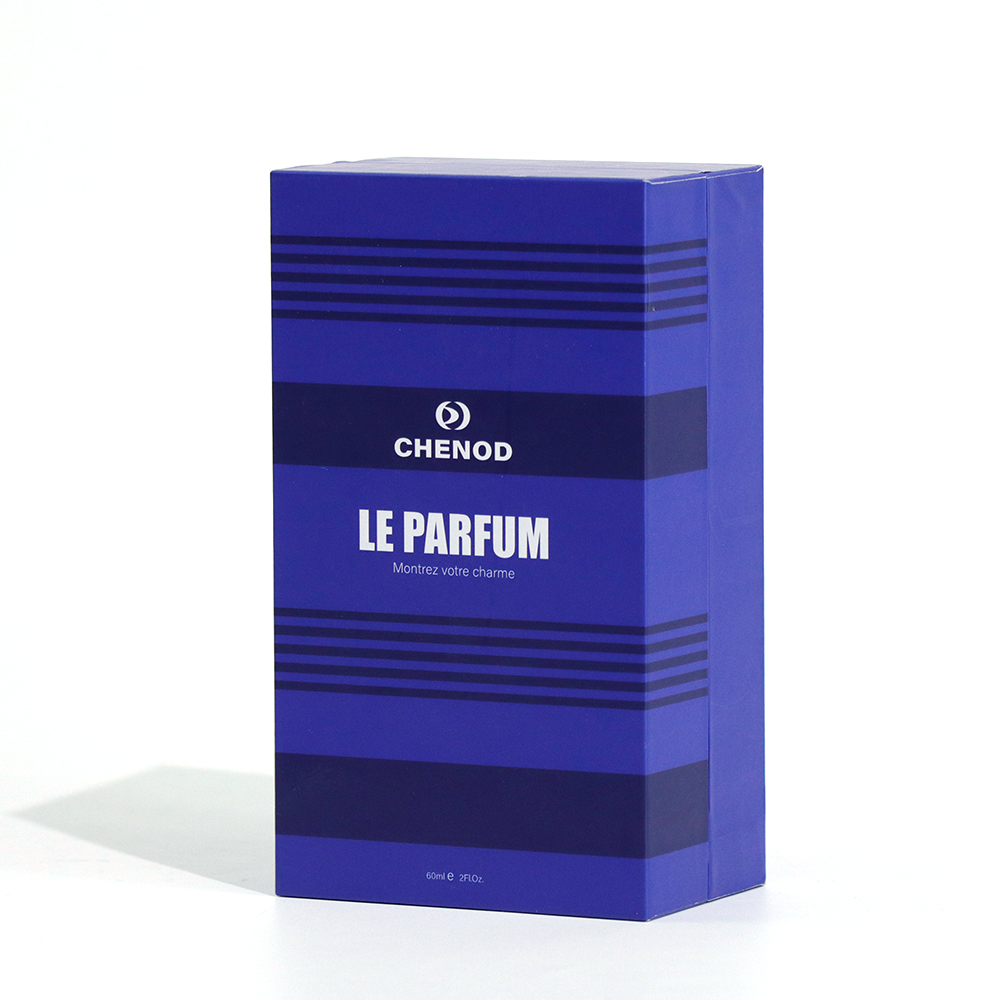

Denna presentförpackning är en gemensam innovation av material, hantverk och design, med hänsyn till funktionalitet, estetik och varumärkeston. Den är lämplig för avancerade parfymer, presentförpackningar för semester eller begränsade gemensamma produkter. Genom en flexibel leveranskedja och strikt kvalitetskontroll ger den kunderna effektiva och tillförlitliga skräddarsydda lösningar.

Beskrivning

1. Materialval: den gyllene kombinationen av bestruket papper och kartong

Den presentförpackning användningsområden bestruket papper som ytpapper. Dess yta är slät och absorberande. Det kan exakt återställa högprecisionsmönster och känsliga gradienteffekter. Det är särskilt lämpligt för mönster med metalliska texturer eller ljus- och skuggnivåer. 1200g enkelsidig kartong används för botten. Tjockleken och bärförmågan mäts strikt för att säkerställa att lådans kropp är stabil och inte lätt att deformera. Samtidigt används den interna strukturdesignen (såsom bikakekartongstoppning) för att förbättra fixeringen av parfymen för att undvika skador som orsakas av skakning under transporten.

2. Utseende: djupt lila ton och fusion av fyrfärgsteknik och spotfärgsteknik

Basfärgen använder djupt lilasom symboliserar elegans och mystik och som passar parfymprodukternas positionering i high-endsegmentet. Fyrfärgstryck (CMYK) används för att uppnå grundläggande färgtäckning, och tryck i spotfärg (t.ex. Pantone färgkort anpassad färg) läggs över för att markera varumärkets LOGO eller speciell struktur för att säkerställa färgmättnad och konsistens. Till exempel antar LOGO-delen den heta stämplingens speciella färgprocess för att bilda ett visuellt fokus på den matta bakgrunden, och den övergripande stilen är enkel men ändå lyxig.

3. Ytbehandling: Matt filmprocess förbättrar användbarhet och skydd

Lådans yta är täckt med matt film, som har egenskaper som antifouling, anti-fingeravtryck och nötningsbeständighet. Ytan är täckt med matt film för att bilda en högkvalitativ matt yta, som kan undvika störning av reflektion och samtidigt förhindra erosion av fukt, olja och alkohol och förlänga livslängden på presentförpackning.

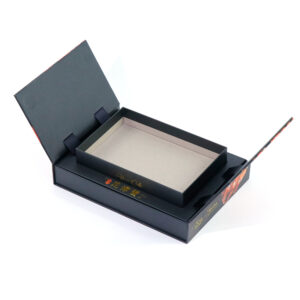

4. Strukturell design: bekvämligheten och den estetiska balansen mellan den övre och nedre lådfliken

Antagande av övre och undre boxklaffstruktur, den övre lådan och den nedre lådan stängs av den magnetiska sugstrukturen, och öppnings- och stängningsvinkeln är upp till 180 °, vilket är lätt att ta och sätta parfym. Förhållandet mellan lådans lock och lådkroppen har optimerats ergonomiskt, vilket kan öppnas och stängas med en hand, vilket är enkelt och snabbt, vilket sparar tid.

5. Personlig anpassning: flexibel anpassning till varumärkets kreativa behov

Lådans yta stöder utskrift i fullbreddoch kan skräddarsy mönster, texter och varumärkesberättelser. Till exempel kan digital tryckteknik användas för att uppnå små partier med hög precision, eller prägling och varmstämplingsprocesser kan kombineras för att förbättra den taktila nivån. Kunderna kan tillhandahålla designutkast eller låta professionella team utföra kreativ design för att säkerställa att presentförpackningen förmedlar varumärkesvärde från utseende till innehåll.

6. Anpassning av lådtyp: flexibilitet för tillämpningar med flera scenarier

Utöver de standardiserade övre och undre lådor, lådtyp, vikningstyp, magnetisk spännetyp och andra diversifierade lådtyper finns tillgängliga. Till exempel kan den avancerade linjen använda en nestningsstruktur med dubbla lager för att förbättra känslan av mysterium, medan den begränsade upplagan kan integreras med en avtagbar liner eller dofttestanordning för att förbättra den interaktiva upplevelsen. Alla typer av lådor har klarat fall- och tryckbeständighetstester för att säkerställa transportsäkerheten.

7. Kapacitetsgaranti: kvalitetskontroll av 5320㎡-verkstaden i hela processen

Vi har våra egna 5320 kvadratmeter intelligent produktionsbas, utrustad med avancerad utrustning som Heidelberg sexfärgstryckmaskiner och helautomatiska stansmaskiner, som stöder full processkontroll från design till leverans. Följ strikt ISO-kvalitetsstyrningssystemet, med en daglig produktionskapacitet på mer än 30 000 stycken, och brådskande beställningar kan levereras på 7 dagar. Det digitala hanteringssystemet övervakar temperatur, luftfuktighet, bläckkoncentration och andra parametrar i realtid för att säkerställa produktkonsistens.