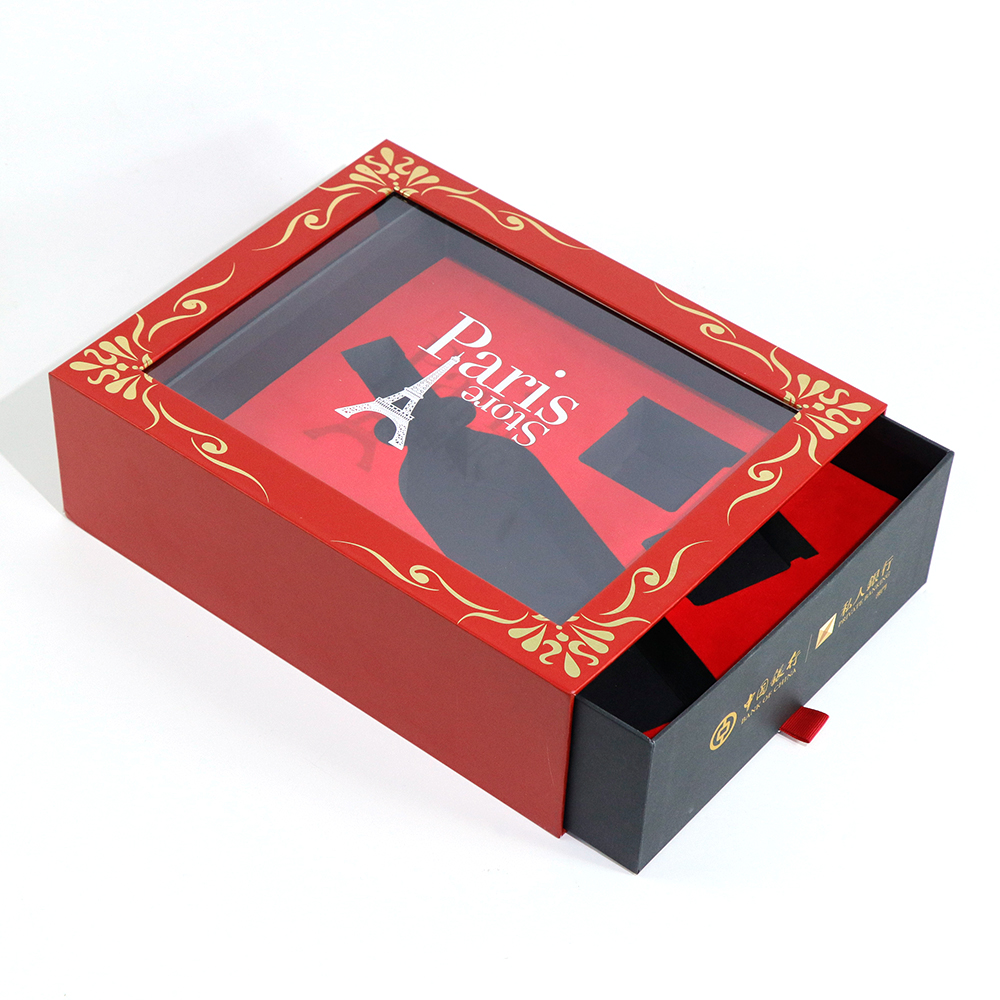

This drawer paper box uses a special color printed coated art paper material, which is environmentally friendly and sustainable. And the area around the window is gold-stamped, giving the box a luxurious feel.

Description

Customized Wine Liquor Spirits Drawer Packaging Paper Box Product Description

1. Paper Craftsmanship: High-end Texture and Visual Impact

- Material and Printing: The paper is made of 300g coated paper, and the brand color is accurately presented through spot color printing technology to ensure high color saturation and distinct layers, which meets the strict requirements of high-end wine packaging for visual quality. The smooth surface of the coated paper can perfectly carry the hot stamping process, highlighting the sense of luxury.

- Hot stamping design: Customize the hot stamping frame around the window area, use metal effects such as mirror gold or rose gold, and combine the embossing process to enhance the three-dimensional sense, create a “picture frame” visual focus, and convey a noble temperament.

2. Window Craftsmanship Combining Touch and Function

- Tactile Texture: The surface of the paper is processed by embossing technology to form delicate cloth or leather texture, which improves the grip while avoiding fingerprint residue, taking into account both practicality and artistry.

- PET film screen printing: The middle window uses 0.5mm transparent PET film, and the brand pattern or gradient effect is printed through high-precision screen printing technology. The light transmittance is more than 90%, which can not only show the appearance of the product, but also give the packaging a modern sense of technology.

3. Lining structure: safety protection and aesthetics

- EVA flocking inner tray: High-density EVA material is die-cut and formed, and 0.3mm short flocking cloth is mounted on the surface. The suede color can be customized according to the main color of the brand (such as wine red, champagne gold). The inner tray groove accurately matches the curvature of the bottle body, and the product stability is guaranteed by physical buffering and friction coefficient. The seismic performance reaches ISTA 3A standard.

- Layered design: The inner box of the drawer can be customized in layers. The upper layer fixes the wine bottle, and the lower layer is embedded with wine utensils or gift slots. The flocking lining forms a color contrast with the black inner box to enhance the visual level.

4. Inner box craftsmanship: minimalist aesthetics and brand identity

- Dutch white paper printing: The inner box uses 350g Dutch white cardboard, which presents a deep black color through four-color overlay printing. The original fiber texture of the white cardboard retains the clarity of the logo, avoiding the color difference problem of ordinary black cardboard, and the Pantone color number error is ≤0.5.

- Structural optimization: The drawer track adopts a “glue-free plug-in” structure, with an opening and closing life of ≥5000 times, and the edge of the inner box is rounded to avoid scratching the flocking surface.

5. Factory strength and service system

- Independent production system: The factory has 8,000 square meters of self-built workshops, equipped with fully automatic hot stamping machines, CNC die-cutting machines and UV silk-screen production lines, supporting proofing within 72 hours, and a monthly production capacity of 500,000 sets.

- Design team support: A 20-person professional design team provides “one-to-one” solution services, customized functional design based on the characteristics of wine (such as anti-counterfeiting label embedding position, humidity sensing window), and has provided innovative packaging solutions for brands such as Moutai and Penfolds.

6. Environmental certification and cost-effectiveness advantages

- FSC certification system: 100% of raw material procurement has passed FSC-COC certification (certificate number FSC-C123456), the carbon footprint of main materials such as coated paper and Dutch white card is 30% lower than the industry standard, and flocking glue meets the EU REACH environmental protection standards.

- Cost control: Cost reduction is achieved through large-scale procurement and process nesting (such as hot stamping and silk screen printing simultaneous plate making). The quotation for similar products is 15%-20% lower than that of traditional packaging factories, and supports a minimum order of 500 pieces.

Technical Parameters

| Project | Parameter Standard |

|---|---|

| Paper Material | 300g coated paper (FSC certified) |

| Hot stamping accuracy | ≤0.1mm positioning error |

| PET film transmittance | ≥90% (ASTM D1003 standard) |

| EVA flocking peel strength | ≥3.5N/cm (GB/T 2792 test) |

| Delivery cycle | 7-15 days (depending on the complexity of the process) |