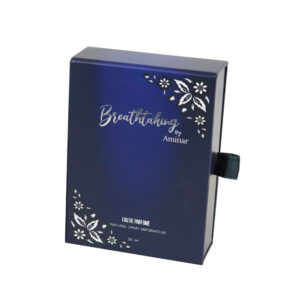

Le système d'ouverture et de fermeture de la boîte à tiroirs est conçu de manière ergonomique, avec un fonctionnement souple et peu contraignant. Il est fabriqué à partir de matériaux certifiés FSC, en tenant compte à la fois des concepts de protection de l'environnement et des propriétés physiques. Il est doté d'un système d'épreuvage rapide en 48 heures, supporte une quantité de commande minimale de 500 pièces et peut être hautement personnalisé pour s'adapter à votre produit.

Description

Description du produit Boîte à tiroirs rigide sur mesure

1. Ergonomique Tiroir Conception

Le tiroir à papier est équipé d'un système d'ouverture et de fermeture du tiroir à papier, combiné à une conception structurelle de précision et à une technologie de moulage de haute précision. Les joints entre les boîte Le corps de l'appareil et le tiroir sont renforcés pour éviter tout relâchement ou blocage, et l'expérience d'utilisation peut être maintenue en douceur même en cas d'utilisation fréquente.

2. Matériaux écologiques certifiés FSC

Les matières premières sont constituées de fibres de bois issues de forêts durables et certifiées par le FSC (Forest Stewardship Council), afin de garantir que l'ensemble du processus de production respecte les normes environnementales. Le matériau tient compte à la fois des concepts de protection de l'environnement et des propriétés physiques, et la résistance à la compression atteint le niveau le plus élevé de l'industrie, protégeant efficacement les produits internes contre les pertes dues au transport.

3. Structure en papier couché à haute résistance

Le boîte La caisse est fabriquée en papier couché de 300g/m², la dureté et la stabilité sont améliorées grâce à un processus composite multicouche, et la capacité de charge peut atteindre plus de 5kg. La conception de l'espace intérieur a été scientifiquement calculée pour soutenir les partitions modulaires (substrat ou compartiments en option), maximiser l'utilisation du volume, et convient aux produits exquis tels que les bijoux et les montres.

4. Poignée en nylon durable

La poignée est fabriquée à partir d'une courroie en nylon très résistant, dont la résistance à la traction est supérieure à 100 kg. Elle ne s'est pas cassée après des dizaines de milliers de tests d'arrachement. En même temps, elle s'adapte à la courbure de la paume de la main pour améliorer le confort de transport. Il est possible de personnaliser la largeur de la poignée, la couleur et l'impression du logo afin d'améliorer la reconnaissance de la marque.

Avantages d'un service et d'une production personnalisés

- Épreuve rapide en 48 heures: Grâce au système d'épreuvage numérique, les rendus 3D et les échantillons physiques sont livrés simultanément afin de restituer avec précision les détails de la conception.

- Quantité minimale de commande flexible: Prise en charge d'une quantité de commande minimale de 500 pièces pour répondre aux besoins de production d'essai des petites et moyennes marques, et réduction du cycle de production de masse à 7-10 jours ouvrables.

- Hautement personnalisé:

- Taille: Hautement personnalisé.

- Technologie: Procédés de traitement de surface optionnels tels que le marquage à chaud, le gaufrage UV, la sérigraphie, le gaufrage, etc., adaptés aux exigences de texture des produits de luxe.

Scénarios applicables et garanties de certification

- Produits concernés: Bijoux haut de gamme, montres, produits de luxe, cadeaux personnalisés et autres produits à forte valeur ajoutée l'emballage.

- Engagement environnemental: L'ensemble du processus est conforme à la certification de la chaîne de production et de supervision des ventes du FSC, et fournit des documents de certification traçables sur les matériaux de protection de l'environnement.

- Service de garantie: Fournir 12 mois d'assurance qualité, soutenir l'inspection qualité par étapes des commandes par lots et assurer la cohérence des livraisons.