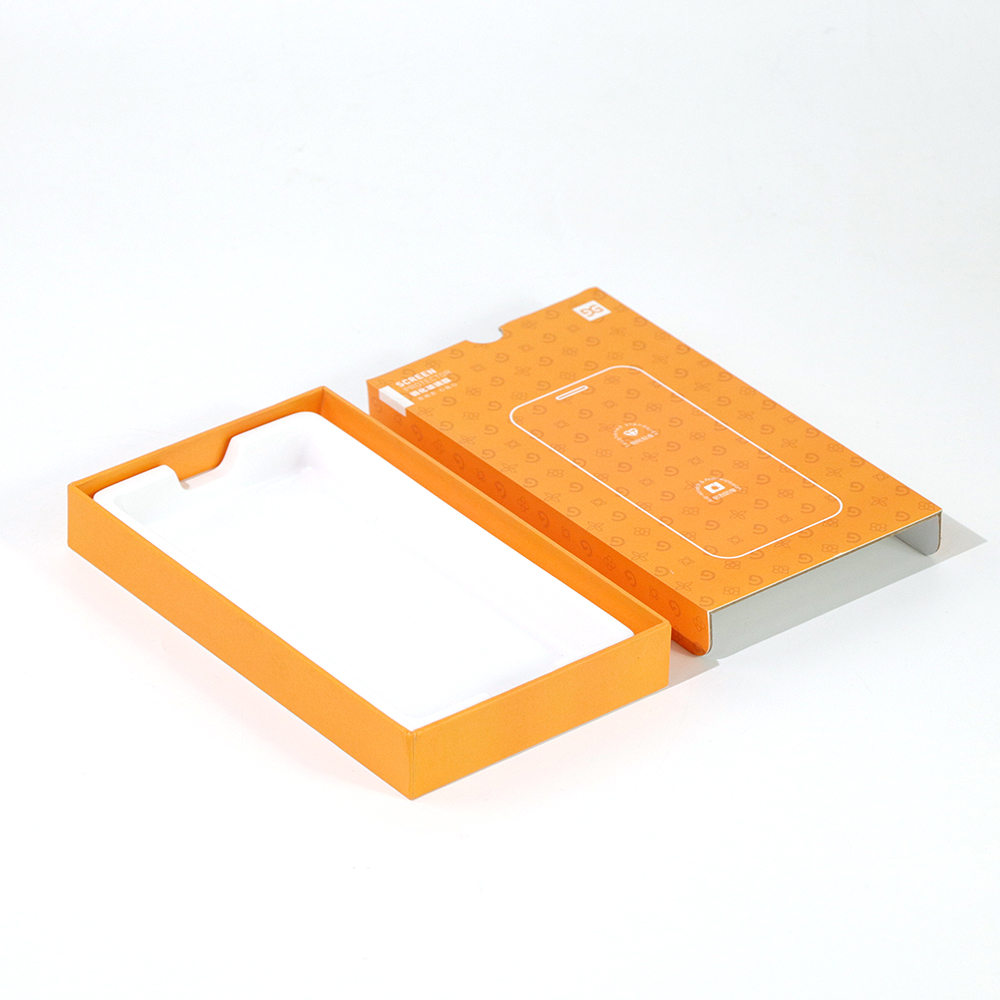

蓋と底が分離したボックスタイプで、開閉方法がシンプルで便利。

説明

カスタマイズされた緩和されたガラス スクリーンの保護装置の包装箱の工場 製品の説明

1.蓋とベースボックスのデザイン:儀式と実用性の両方

- クラシックな蓋とベースの構造 上部と下部のカバー ボックス 上蓋と下蓋が分離したデザインは、開閉が簡単で便利で、製品に独特な儀式感を与えます。箱本体は精密な金型によってカットされ、誤差は±0.1mm以内に管理されているため、閉じたときにしっかりとフィットし、製品の高級な質感を高めている。

- 保護と利便性の最適化 箱体の材料は1200GSM灰色板基材と157G銅板紙の複合加工を採用し、変形がなく、静圧50kgの圧縮強度があり、輸送中の押し出しや衝突に効果的に耐える。磁気吸引構造を埋め込み、閉じた時のフィット誤差は≤0.2mmで、片手でスムーズに開閉でき、安全性と利便性を考慮した。

2.オレンジのメインビジュアルデザイン:ブランドの活力を刺激する

- 色彩心理学がブランドに力を与える オレンジをメインカラーとし、低彩度グラデーション技術と組み合わせることで、活力、温かさ、ポジティブな感情を伝える。オレンジの波長(590-610nm)は、視覚への浸透と快適さのバランスをとり、棚の認知度を20%-30%高め、消費者のブランドに対する記憶を高めることができる。

- ブランド・ロゴの明確な表示 表面は4色オフセット印刷技術を採用し、Pantone色番号の正確なマッチングをサポートし、印刷の色差がないことを保証します。ブランドロゴは、ホットスタンピング、UVまたはエンボス技術と組み合わせることで、オレンジ色のベースに強い視覚的コントラストを形成し、ブランド効果を強化することができます。

3.カスタマイズされた適応ソリューション:製品ニーズに的確に対応

- ボックスタイプの柔軟なカスタマイズ フルサイズの適応をサポートし、排他的なカスタマイズが可能 ボックス 強化フィルムの大きさ(厚さ0.15mm~0.33mmなど)や表面の曲率(2.5D/3D/等深度4曲面)に応じて種類がある。例えば

- 超薄型バージョン:0.15mmの超薄型強化フィルムに適し、箱の厚さは1.5cm以内に制御される;

- 曲線バージョン:3D熱曲げ強化フィルム用U字溝インナーサポートは、フィルムの曲率にフィットするように設計されています。

- 多様なライニング素材の選択肢 EVA植毛、絹布、厚紙、スポンジなどの裏地オプションを提供する:

- EVAフロッキング:優れた耐衝撃性能を持ち、精密強化フィルムのエッジ保護に適しています;

- シルクの裏地:繊細なタッチで、高級ギフトレベルの包装に適しています;

- スポンジのレイヤリング:複数の強化フィルムをパーティションに収納でき、傷がつきにくく省スペース。

4.中国のソース工場の利点:ワンストップサービスとコストの最適化

- 無料サンプルとデザイン・サポート 無料の校正サービスを提供し、3-5営業日以内に物理的なサンプルを送信し、箱の種類、印刷、および裏地のフル次元の調整をサポートしています。デザインチームはブランドVIシステムに基づいて、包装構造の最適化と視覚ソリューションのカスタマイズを提供し、顧客の開発コストを削減することができます。

- 費用対効果の高い大量生産ソリューション 広東省東莞市/深圳市にある供給元工場として、自動化された生産ラインを採用し、10個からの注文に対応している。一個のコストは ボックス は市場平均価格より30%-40%低い。OPP袋、ブリスターボックス、カラーボックスなど様々な包装オプションを提供し、越境物流や小売のニーズに応えている。

- 品質と認証の保証 ライニング材は医療グレードの規格(YY/T 0114)に適合し、ボックス本体は-25℃~50℃の温湿度サイクルテストに合格し、世界的な輸送の安定性を確保している。CE認証と環境に優しいインク印刷をサポートし、欧米での市場参入の要件を満たしています。

5.技術パラメーターとサービスプロセス

| プロジェクト | パラメータ/サービス詳細 |

|---|---|

| ボックスタイプ | 上蓋と下蓋(引き出し式、窓式、その他のバリエーションをカスタマイズ可能) |

| 素材 | 157Gコート紙+1200GSMグレーボード、表面マットフィルム |

| 印刷工程 | 4色オフセット印刷+部分的なUV/ホットスタンピング、パントンカラーマッチング |

| 配達サイクル | サンプルの場合3~5日、大量生産の場合7~15日(速達対応) |

| 物流包装 | 独立OPP袋+耐衝撃ハニカムカートン、DHL/FedEx直送対応 |