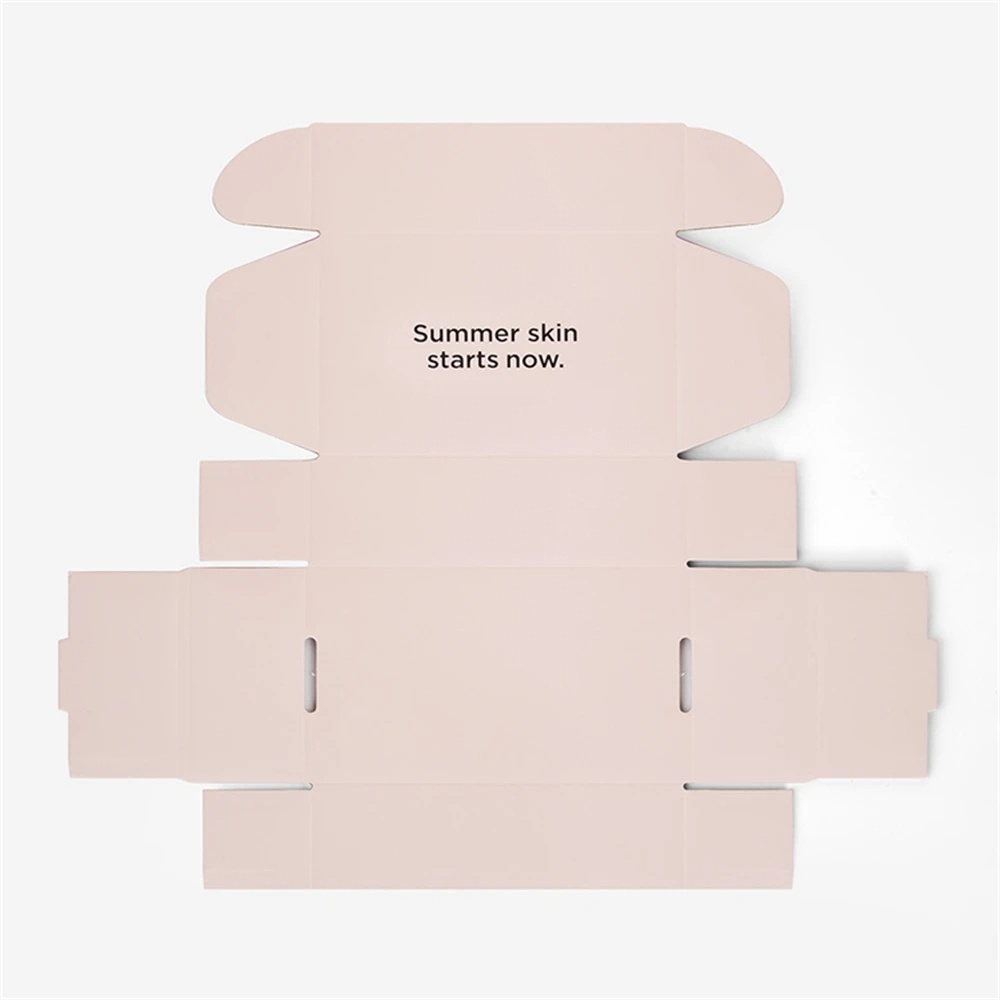

이 우편함은 골판지로 제작되어 운송 중 충격을 효과적으로 완충하고 향수 및 미용 제품을 보호할 수 있습니다. 접으면 평판이 되어 공간을 거의 차지하지 않고 보관 비용도 절감할 수 있습니다.

설명

친환경 화장품 향수 배송 포장 공급업체

1. 접착제가 필요 없는 포장 기술, 초고속 포장 경험

특허받은 우편함 구조를 채택하고 정밀한 주름 디자인과 자동 잠금 장치를 사용하여 "접착제 필요 없음, 한 번 접고 닫기"를 달성하고 포장을 단 30 초 만에 완료 할 수 있으며 이는 기존 테이프 포장보다 60% 이상 더 효율적입니다. 이 기술은 테이프 오염을 제거할 뿐만 아니라 전자상거래의 빈번한 배송 시나리오에 완벽하게 적용되는 도난 방지 찢김선 디자인을 통해 '한 번 당겨서 열기'라는 편리한 포장 풀기 경험을 실현합니다.

2. 고강도 골판지 소재, 3중 보호 시스템

선별된 A/B/C 복합 골판지(수량 280~360g/m²)를 사용했으며, 충격력은 UV 골판지 구조를 통해 분산됩니다. 실험실 데이터에 따르면 5층 골판지 구조는 1평방미터 면적에 0.5톤의 중량 압력을 견디는 것과 같은 5000N/m²의 수직 압축 강도를 견딜 수 있는 것으로 나타났습니다. 표면 코팅 공정으로 내습성(습도 허용 오차 ≥ 85%RH)이 향상되었으며 내부 허니콤 완충층이 운송 진동을 효과적으로 흡수하여 1.2m 낙하 테스트에서 향수 유리병이 전혀 손상되지 않도록 보장합니다.

3. 평면 접이식 수납, 공간 활용도 70% 증가

펼친 크기는 1200×800mm, 접은 후 두께는 3.2cm에 불과해 200개/세제곱미터의 보관 밀도로 쌓을 수 있습니다. 독특한 'Z자형' 접이식 라인 디자인으로 역전 펼침이 가능하며 재활용 시 분해 없이 평평한 상태로 복원할 수 있어 전체 창고 및 물류 비용을 절감할 수 있습니다. 기존 포장에 비해 동일한 양의 상품에 필요한 보관 용량이 45% 감소하여 계절별 인기 제품이나 기간 한정 프로모션의 유연한 재고 확보에 특히 적합합니다.

4. 풀체인 환경 인증, 제어 가능한 분해 주기

이 소재는 FSC 산림 인증을 통과했으며 수성 잉크 인쇄와 옥수수 전분 접착제를 사용하여 180일 이내에 95% 이상의 자연분해율을 보장합니다. 포장 수명 주기 평가(LCA)에 따르면 원료 수거부터 폐기물 처리까지 전 과정의 탄소 발자국은 PE 플라스틱 포장에 비해 82%가 적습니다. ON&DO 브랜드와 동일한 무접착 포장 기술을 사용하여 생산부터 재활용까지 접착제 무공해 폐쇄 루프를 실현했습니다.

5. 감성적 공명을 일깨우는 부드러운 핑크색 시각 시스템

팬톤 13-2807TCX '첫사랑 핑크'부터 14-1312TCX '로즈 쿼츠 핑크'까지 12가지 맞춤형 컬러를 제공하며, 무광 라미네이션 기술을 사용하여 4페이지에 설명된 대로 '따뜻한 피부 촉감'을 표현합니다. 엠보싱 핫 스탬핑, 부분 UV 및 기타 공정과 결합하여 상자에 꽃무늬 질감이나 브랜드 로고를 인쇄할 수 있습니다. 경험적 연구에 따르면 핑크색 포장의 향수 개봉 전환율은 무채색보다 23% 높아 발렌타인데이, 어버이날과 같은 감성 마케팅에 특히 적합한 것으로 나타났습니다.

6. 유연한 커스터마이징 서비스로 브랜드 차별화 강화

컨셉부터 구현까지 전체 프로세스 사용자 지정을 지원합니다:

- 박스형 혁신육각 프리즘, 하트 모양 등 특수한 모양의 구조물 개발 가능

- 기능 확장내장형 자석 플립 커버, 분리형 리필 카드 슬롯

- 스마트한 통합NFC 칩을 탑재하여 위조 방지 추적성을 달성하거나 AR 기술과 결합하여 역동적인 향기 스토리를 선사합니다.

- 장면 적응: 5ml 트라이얼 팩부터 1000ml 비즈니스까지 풀 사이즈 제공 선물 상자전자 상거래 다이렉트 메일, 카운터 디스플레이, 국경 간 운송 등 다양한 시나리오의 요구 사항을 충족합니다.

기술 매개 변수

| 항목 | 표준 값 | 테스트 기준 |

|---|---|---|

| 압축 강도 | ≥485kgf(최대 부하) | GB/T 6546-2021 |

| 수분 함량 | 8.5±1.2% | ISO 287:2017 |

| 성능 저하 주기 | ≤토양에서 180일 이내 | ASTM D6400 |

| 인쇄 정확도 | 175개의 고화질 도트 라인 | G7 색상 인증 |

협력 프로세스

- 수요 진단: 48시간 이내에 패키징 전략 보고서 제공(경쟁 제품 분석 및 비용 최적화 제안 포함)

- 증명 검증: 영업일 기준 5일 이내에 3D 구조 도면 및 실제 샘플 박스 제공

- 대량 생산 보장: 하이델베르크 7색 인쇄기를 갖춘 자체 공장, 50만~500,000개의 유연한 주문 지원

- 판매 후 추적: 12개월 품질 보험 및 손해율 보상 플랜 제공