상하로 구성된 종이 튜브 패키지는 마카롱 색상을 조합하여 따뜻한 분위기를 연출할 수 있습니다. 뚜껑 상단에는 검은색 로고가 양각되어 있어 소비자가 브랜드를 한눈에 알아보고 깊은 인상을 남길 수 있습니다.

설명

커피 캔들 화장품용 맞춤형 종이 튜브 제조업체

1. 따뜻한 분위기의 미적 디자인

원통형 상하 구조를 채택하고 박스 바디는 마카롱 컬러 그라데이션 조합(크림 화이트, 피치 핑크, 민트 그린 등)을 지원하며 매트한 질감과 부드러운 컬러 매칭을 통해 따뜻하고 힐링이 되는 시각적 분위기를 연출합니다. 내부 레이어를 코팅하여 채도와 내구성을 향상시킬 수있어 커피 원두와 같은 고급 장면에 적합합니다. 선물 상자아로마테라피 캔들, 스킨케어 세트 등 다양한 제품을 만나보세요.

2. 브랜드 로고 향상 디자인

상자 뚜껑 상단에는 정밀 엠보싱 기술을 채택하여 고대비 블랙 브랜드 로고를 표현하고 입체 엠보싱 또는 핫 스탬핑 기술을 지원합니다. 예를 들어 화장품 종이 캔은 메탈릭 광택 로고와 매칭하여 무광택 상자 본체와 시각적 대비를 형성하여 브랜드 인지도를 높이고, 양초 패키지는 볼록 및 오목 엠보싱을 통해 질감을 전달하여 북유럽 미니멀리스트 또는 레트로 라이트 럭셔리 스타일에 적합할 수 있습니다.

3. 비용 효율적인 재료 선택

본체는 180-300g 코팅지 복합 구조를 채택하고 내부 층은 식품 등급 알루미늄 필름 또는 방습 코팅으로 적층되어 있습니다 (화장품의 경우 항균 처리는 선택 사항). 코팅지의 두께는 하중지지 요구 사항 (예 : 양초 병은 지지력을 강화해야 함)에 따라 조정할 수 있으며 비용은 기존 철 캔보다 30%-50% 낮습니다. 동시에 ISO 9001 품질 관리 인증을 통과하여 50kg 이상의 압축 강도를 보장합니다.

4. 유연한 인쇄 및 레이아웃 혁신

- 패턴 사용자 지정: 오프셋 인쇄, UV 부분 광택 표면, 스크린 인쇄 및 기타 다중 프로세스 조합을 지원하여 일러스트레이션, 기하학적 질감, 그라데이션 스머지 및 기타 디자인을 표현할 수 있습니다. 예를 들어 커피 포장에는 원산지의 일러스트를 인쇄하고 화장품 캔에는 추상적인 아트 라인과 매치할 수 있습니다. - 기능성 인쇄: QR코드 추적 라벨, 사용 지침 또는 대화형 그래픽(향신료 성분 다이어그램 등)을 추가하여 사용자 경험을 개선하세요.

5. 전체 프로세스를 위한 원스톱 서비스

3D 모델링 및 교정부터 대량 생산 및 배송까지 제공합니다: - 디자인 지원: 전문 팀이 구조 최적화(상단 및 하단 뚜껑 개폐의 감쇠 계수 등), 색상 보정 및 규정 준수 검토(화장품 포장의 라벨 사양 등)를 지원합니다. - 생산 관리: 자동 튜브 와인딩 기계와 시각적 위치 지정 용지 라미네이팅 기계를 채택하여 ± 0.5mm 치수 정확도를 보장하고 월 50 만 개 생산 능력으로 긴급 주문에 대해 7 일 신속한 생산을 지원합니다.

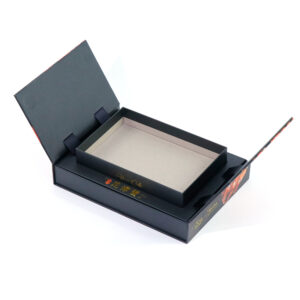

6. 정밀 안감 매칭 시스템

제품 형태(테이퍼 캔들, 원통형 파운데이션 병 등)에 따라 맞춤형 EVA/PEP 내부 트레이를 제공합니다: - 고정 구조: 스냅온 레이어드 디자인으로 운송 중 흔들림을 방지하고 화장품에 충격 방지 버블 필름을 추가할 수 있습니다. - 기능 확장: 자석 개폐, 리본 핸들 또는 탈착식 파티션을 추가하세요. 선물 상자 조합을 설정합니다.

협력의 이점

- 환경 인증: FSC 산림 인증 용지 + 생분해성 잉크, EU EN 13432 퇴비화 가능 표준에 부합합니다. - 부가 가치 서비스: 시장 기회를 포착하는 데 도움이 되는 무료 경쟁 제품 패키징 분석 보고서 및 분기별 트렌드 가이드를 제공합니다.