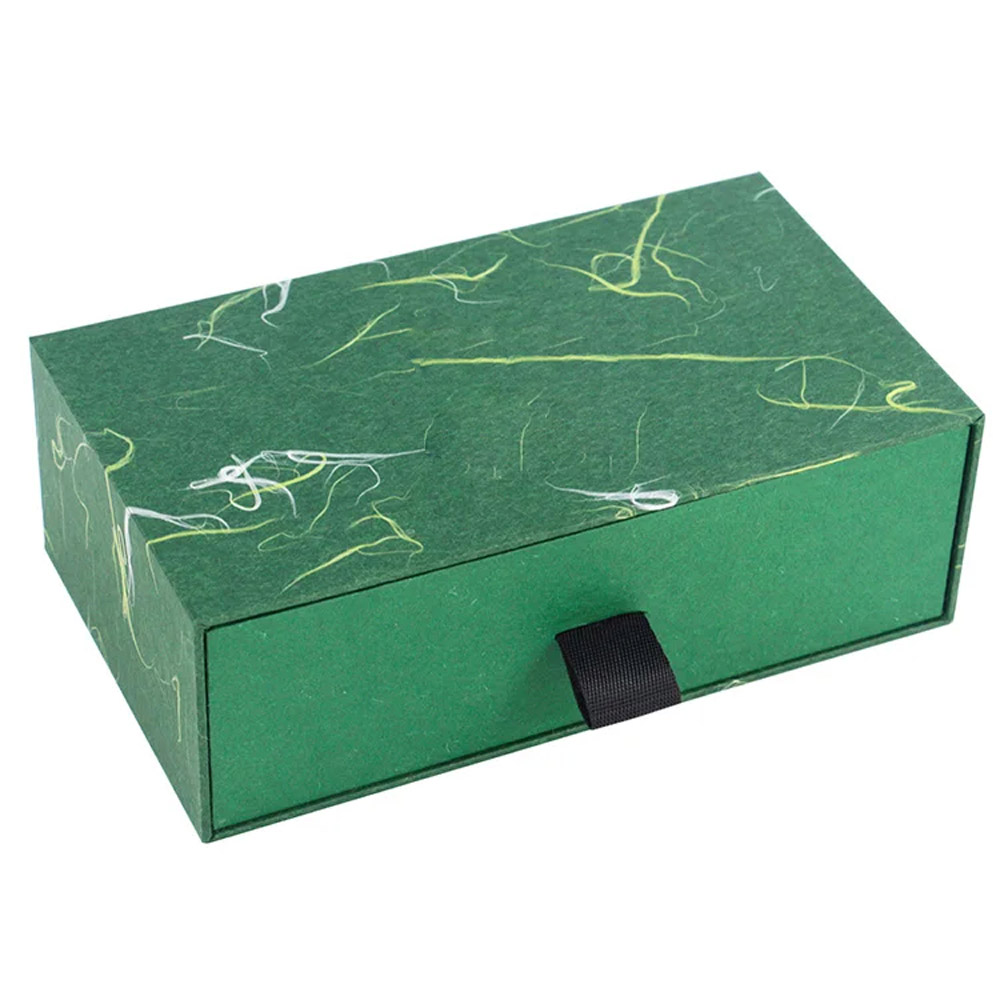

The drawer perfume gift box features a sliding rail design that creates a sense of ritual when opened. High-precision EVA grooves are embedded to allow the perfume bottle to be “suspended” and fixed. The natural texture of the herbal scented paper and the detailed metal label create a tranquil and luxurious experience. The box is cut with millimeter-level die-cutting, resulting in sharp edges and corners. Its dark green primary colorway is complemented by an artistic embossed silk screen print, creating a sustainable visual classic. 3D modeling is supported for rapid proofing, with global delivery within 15 days.

Description

Deluxe Fragrance Drawer Packaging Gift Boxes: Accuracy Workmanship Fulfills Classic Beauty

Made with thorough interest to detail, our luxury fragrance cabinet product packaging boxes integrate innovative design and opulent visual appeals to redefine fragrance presentation. Below is a comprehensive item spec straightened with your requirements:

1. Smooth Drawer Device

- Push-Pull Style: Utilizing an advanced mix of an outer box (outside real estate) and an internal drawer (internal drawer), coupled with a moving rail base, makes certain smooth opening and closing, flawlessly personifying the unboxing ritual of high-end perfumes. The rail sides are polished to the millimeter degree to remove burrs and supply a silky-smooth responsive experience.

- Ingenious Opening and Closing: Deserting the standard pull-out layout, this box includes an optional spring-driven system for a light touch, getting rid of the threat of the fragrance bottle shaking because of excessive force.

2. Internal Protection System | Precision Cradle & Defense

- Customized Groove Dealing With: Based on 3D modeling information, a specific groove is cut right into the drawer’s internal box, firmly covering the perfume container for a “floating” secure fit. The groove is lined with high-density, eco-friendly EVA foam (adjustable density) to properly absorb transport vibrations and avoid scratches and leakages.

- Dual Defense Design: A hollow framework at the bottom of the groove allows for very easy one-handed access to the fragrance bottle. An anti-static finishing can also be included in prevent fixed sparks triggered by rubbing with the container.

3. Box Product & Feeling | Natural Appearance & Tactile Luxury

- Natural Appearance Surface Area: Made from imported herbal perfumed paper or artistically embossed paper, the natural fiber appearance is protected, offering package a matte finish and a warm touch. The surface is treated with a water-based finishing for dampness and finger print resistance.

- 3D Decorative Workmanship: Irregular yellow and white textures are accomplished via imaginative embossing and display printing, creating a three-dimensional texture (concave and convex depth 0.3– 0.5 mm) and with wear resistance of up to 10,000 friction cycles without peeling off.

4. User-Friendly Information | Fine-tuned Useful Aspects

- Opening Support: An embedded black woven cotton deal with (width ≥ 15mm) improves cabinet opening convenience; the handle is safeguarded with a steel rivet at the end to make certain lasting deformation.

- High-end Logo Style: The metal brand name tag is electroplated with zinc alloy, readily available in gold, platinum, or bronze. Micro-etching technology achieves a logo design depth of ≤ 0.1 mm.

5. Shade and Aesthetic Logic | Iconic Shade Strategy

- Standard Luxury Color: A deep dark green (Pantone 627C) is the primary, inhabiting ≥ 85% of the box surface, signifying nature and eternity. The matte black drawer tops and steel labels create a contrast of light and dark, improving the aesthetic power structure.

- Lasting Shade Handling: Printed utilizing plant-based water-based ink, the shade discrepancy is ≤ 0.5 ΔE (worldwide requirement), and it follows FSC environmental certification.

6. Precision Production Criteria | Millimeter-Perfect Design

- Mold Precision Control: Package body makes use of a CNC precision-carved mold and mildew (resistance ± 0.05 mm), leading to sharp corners and no chipping. The cabinet rail clearance is ≤ 0.2 mm, ensuring smooth moving and drawing.

- Dust-Free Manufacturing Environment: The whole procedure is completed in a Course 10,000 cleanroom, removing dust contamination and guaranteeing a beautiful surface area texture.

7. Rapid Development Capabilities | Agile Prototyping & Manufacturing

- Digital Development Process: Supports 3D modeling (Rhino/SolidWorks) for real-time simulation of the box framework. Laser-cut examples can be verified within 8 hours, speeding up style versions.

- Versatile production feedback: Automation cycle is 15-20 days (consisting of tailored processes), sustains MOQ 500 pieces, and works with OEM/ODM demands.