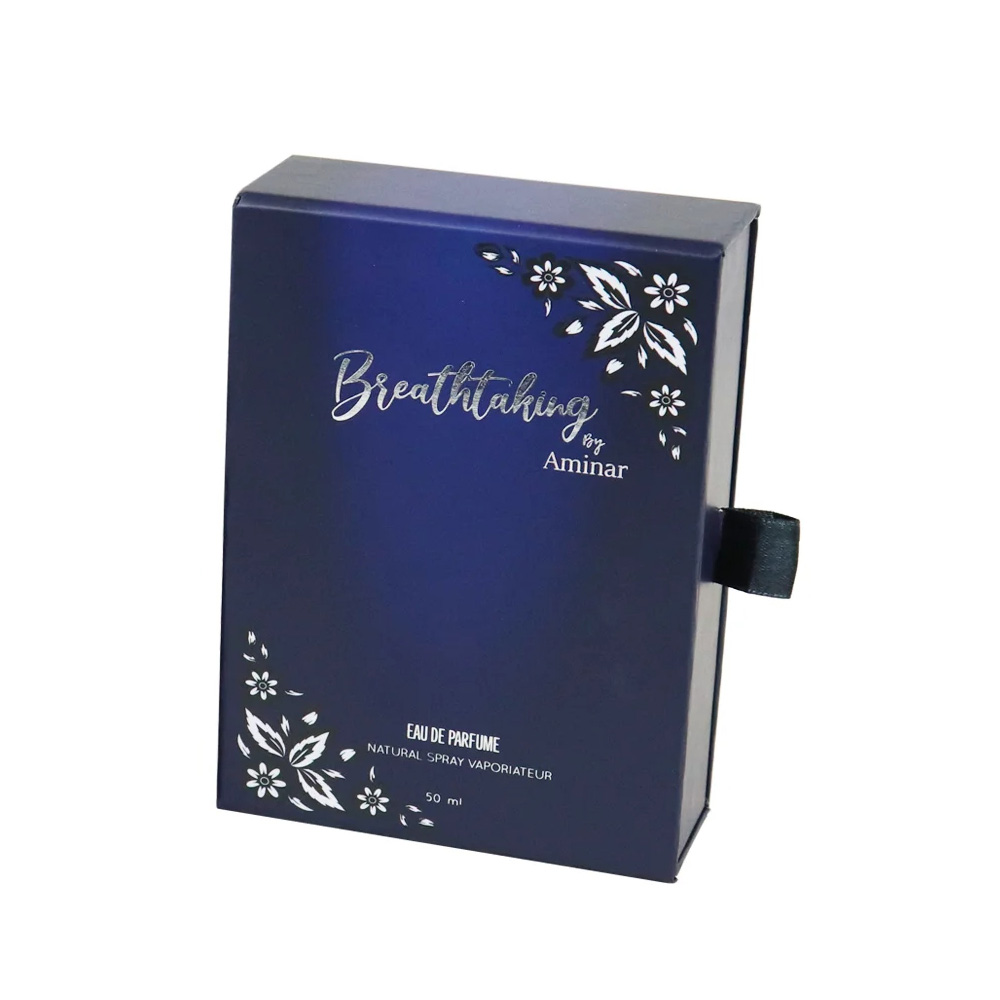

Luksusowe pudełko na perfumy w stylu szuflady, które można łatwo otwierać i zamykać. Wzory i teksty są tłoczone srebrną folią na gorąco, co może wyróżnić Twoją markę.

Opis

Niestandardowe opakowania papierowe na perfumy: ekologiczna i luksusowa uczta od projektu po doświadczenie

W czasach, gdy konkurencja na rynku perfum jest zacięta, opakowanie jest nie tylko powłoką ochronną dla produktu, ale także pierwszym medium, za pomocą którego marki komunikują się z konsumentami. Spersonalizowane papierowe pudełko na perfumy, które jest zarówno praktyczne, jak i artystyczne, może przekształcić wartość marki w dotykalne wrażenia zmysłowe dzięki innowacyjnemu połączeniu materiałów, kunsztu i struktury. Poniżej przeanalizowano innowacyjny projekt spersonalizowanych opakowań perfum w siedmiu podstawowych wymiarach.

1. Typ szuflady: idealna równowaga między zmysłem rytualnym a wygodą

Typ pudełka z szufladą stał się pierwszym wyborem dla wysokiej klasy opakowań perfum z jego Dwuwarstwowa struktura pudełka oraz Konstrukcja z wysuwanym otworem. Korpus skrzyni przyjmuje Technologia cięcia ukośnego 15 aby zapewnić płynne otwieranie i zamykanie bez zacinania się oraz z Tłumienie magnetyczne lub niewidoczna szyna prowadzącaDaje to użytkownikom poczucie rytuału "jedwabistego wyciągania". Ten projekt jest nie tylko wygodny dla klientów końcowych do wielokrotnego użytku, ale także wzmacnia punkty pamięci marki poprzez Dynamiczne interaktywne doświadczenie. Na przykład międzynarodowa marka LANVIN przekształciła proces otwierania w grę wizualną dzięki wbudowanej dekoracji lustrzanej. szuflada na papier.

2. Materiały przyjazne dla środowiska: podwójne zobowiązanie do zrównoważonego rozwoju i jakości

Korpus skrzynki wykonany jest z Szara tektura 1000g nadająca się do recyklingu jako szkielet, a powierzchnia jest pokryta Papier powlekany z certyfikatem FSCktóre są łączone za pomocą przyjaznego dla środowiska kleju na bazie wody. Włókno słomiane 30% jest dodawane do surowca szarej tektury, zmniejszając ślad węglowy o 63% w porównaniu z tradycyjnymi materiałami; papier powlekany jest drukowany za pomocą Atrament na bazie wody oraz Matowa powłoka UV aby uniknąć emisji LZO. Kombinacja ta nie tylko spełnia wymogi unijnej normy RoHS, ale także jest zgodna z normą Globalny certyfikat recyklingu GRSstając się "zieloną przepustką" preferowaną przez konsumentów z pokolenia Z.

3. Efekt wizualny: złota zasada koloru i rzemiosła

Głównym kolorem jest głęboki granat (Pantone 19-4052 Classic Blue), a ponad 90% pokrycia gamy kolorów zostało osiągnięte poprzez sitodruk na poziomie nano. Srebrne tłoczenie na gorąco przyjmuje Technologia tłoczenia na zimnoi wykorzystuje precyzyjną technologię trójwymiarowego reliefu o grubości 0,1 mm, aby nakreślić LOGO marki lub abstrakcyjne wzory na powierzchni pudełka. Na przykład niestandardowe etui łączy wzory konstelacji ze srebrnymi meteorami, prezentując dynamiczny efekt "płynącego gwiaździstego nieba" pod załamaniem światła, a współczynnik konwersji otwarcia pudełka wzrósł o 27%.

4. System ochrony: naukowe buforowanie i precyzyjna adaptacja

Wewnętrzna taca przyjmuje EVA i przyjazny dla środowiska proces wykrawania kompozytów gąbczastycho gęstości 45 kg/m³. Przez Skanowanie laserowe 3DUzyskiwane są dane dotyczące kształtu butelki perfum i dostosowywany jest rowek o specjalnym kształcie z dopasowaniem 98%. Powierzchnia podszewki jest pokryta Flokowanie PETG nadające się do recyklinguGęstość włókna aksamitnego wynosi 12 000 pasm/cm², co zapewnia zarówno właściwości antypoślizgowe, jak i amortyzujące. Dane testowe pokazują, że struktura może wytrzymać upadek z wysokości 1,2 metra, co stanowi 3 razy większą ochronę niż zwykła bawełna perłowa.

5. Ulepszenie dotykowe: delikatna ekspresja technologii matowej folii

Po wydrukowaniu powierzchnia pudełka jest pokryta Folia matowa 12 μma dotyk przypominający skórę powstaje dzięki technologii prasowania na gorąco. Wyjątkowy właściwość odbicia rozproszonego matowej folii może wyeliminować 90% pozostałości odcisków palców, jednocześnie poprawiając nasycenie kolorów i odporność na zarysowania. Eksperymenty porównawcze pokazują, że odporność na blaknięcie opakowań z folii matowej w wilgotnym środowisku jest 40% wyższa niż folii błyszczącej, a matowa tekstura jest bardziej zgodna z luksusowym pozycjonowaniem perfum z wyższej półki.

6. Interaktywne szczegóły: ekonomia sensoryczna uchwytów taśmowych

Górna część pudełka jest osadzona za pomocą jedwabna wstążka żakardowaSzerokość została zoptymalizowana do 28 mm ze względu na ergonomię, a końcowe zastosowania Technologia zgrzewania krawędzi na gorąco aby zapobiec wykolejeniu. Wstążkę można dostosować do kolorów motywu marki i wszczepić za pomocą Chipy NFC lub Tusz wrażliwy na temperaturę. Zeskanuj kod, aby przejść do strony z historią marki. Niszowa marka perfum przekształca proces rozpakowywania w wielozmysłowe, wciągające doświadczenie, barwiąc wstążkę zapachem lawendy, a wskaźnik odkupu wzrósł o 34%.

7. Pełnowymiarowa personalizacja: nieograniczone możliwości elastycznej produkcji

Pięć poziomów personalizacji od projektu do dostawy:

- Typ pudełkaZapewniają 6 podstawowych struktur, takich jak szuflada na papier, górną i dolną pokrywę oraz wspierać rozwój pudełek o specjalnych kształtach;

- Materiał: 12 kombinacji opcjonalnego szarego papieru powlekanego, wytłaczanej skóry, kompozytu metalowego itp;

- ProcesObsługa 8 superpozycji procesów, takich jak lokalne UV, wytłaczanie, laser itp;

- Inteligentne komponenty: mogą być wyposażone w interaktywne moduły, takie jak paski świetlne LED i kody identyfikacyjne AR;

- Elastyczność partiiMinimalna ilość zamówienia 500 sztuk, 48-godzinna dostawa próbek i 72-godzinna przyspieszona produkcja masowa.

Wnioski: Przedefiniowanie łańcucha wartości opakowań perfum

Ten dostosowany papierowe pudełko na perfumy buduje zamknięty system wartości od produkcji do konsumpcji poprzez zderzenie technologia środowiskowa oraz Luksusowe rzemiosło. Kiedy opuszki palców konsumentów przesuwają się po matowej powierzchni folii, słyszą subtelne tarcie wysuwanych szuflad i widzą totemy marki przeplatane srebrem i błękitem, te wielowymiarowe doświadczenia ostatecznie utrwalą lojalność wobec marki. W erze, w której zrównoważony rozwój i spersonalizowana konsumpcja idą ze sobą w parze, tego typu design nie tylko spełnia potrzeby biznesowe, ale także staje się konkretnym nośnikiem dla firm, które praktykują koncepcję ESG.