このカスタムハンドメイドチョコレート伸縮包装ボックスは、実用性と美的価値を考慮し、絶妙な職人技と革新的な構造を統合し、ハイエンドの食品包装用に設計されています。環境に優しい材料と柔軟なカスタマイズサービスを採用し、チョコレート、キャンディー、カップケーキなど多様な食品包装シーンに適しており、ブランドが製品イメージと市場競争力を高めるのに役立ちます。

説明

カスタマイズされた手作りの職人チョコレート伸縮包装ボックス卸売製品の説明

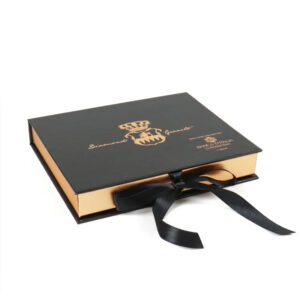

1. 優れた印刷技術でブランドの質感を際立たせる

- 高精度のオフセット印刷技術を使用し、鮮明で繊細なパターン、均一で完全な黒インク、98%色域カバー率、偏差のない純粋な色、ブランドロゴとデザイン要素の完璧な表現を保証します。

- ホットスタンピング、UVローカルニスおよび他のプロセスをサポートし、エンボス加工されたテクスチャやメタリック光沢効果と一致させることができ、視覚的なレイヤリングと豪華な経験を強化する。 パッケージング.

2. 硬い素材の組み合わせ、製品の全面的な保護

- 外箱はオランダから輸入した透明グレーボード(厚さ1.5~3.0mm)と300gコート紙の複合製法を採用。グレーボードは層間接着が強く、圧力や衝撃に強く、輸送中の押し出し変形に効果的に耐える。

- 箱の構造は最適化されており、1.2kg以上の耐荷重が可能で、長距離物流や倉庫保管のニーズに適している。

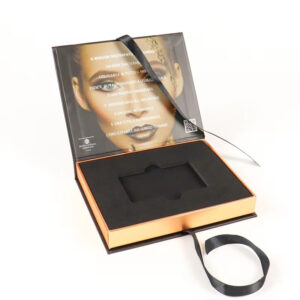

3. マグネット開閉式ボックスのデザインで、開閉感がアップ

- 蓋には0.8mmのシリコンが内蔵されています。 マグネット開閉式ボックス モジュールの吸着力は1.2kg。片手で簡単に開閉でき、従来のバックルが緩みやすいという問題を回避し、しっかりと閉じることができる。

- 箱はブック型のフリップカバー・デザインを採用。180度折りたたむと、商品が一目瞭然になり、陳列効果や消費者とのインタラクションが高まります。

4. 柔軟なライニング・パーティションで、複数のシーンに対応可能

- 標準的な厚紙の裏地は、24/36グリッドの精密分割をサポートし、グリッドの深さと間隔は調整可能で、手作りチョコレート、トリュフ、その他の特殊な形状の製品に完璧にマッチします。

- オプションのEVA、スポンジ、またはフロッキングのライニングは、厚さ2~10mmの範囲で、脆いキャンディーや壊れやすいケーキに適した、カスタマイズされた緩衝ソリューションを提供します。

5. マルチフィールド対応、アプリケーションシナリオの拡大

- チョコレートだけでなく、箱のサイズは8cm×8cmから30cm×30cmまでカスタマイズでき、マカロン、クッキー、ナッツなどの食品に適しています。 パッケージング.

6.徹底したカスタマイズサービス

- 外観のカスタマイズ:パントンカラーカードの正確なカラーマッチング、3Dモデリングプルーフサービス、エンボス加工、中空窓、その他のパーソナライズされたデザインをサポートします。

- 構造の最適化:製品重量(≤2kg)に応じてグレーボードの重量(250〜400gsm)を調整するか、耐荷重性能を向上させるために補強リブ設計を追加します。

- 機能アップグレード:オプションの防湿コーティング、取り外し可能なパーティション、QRコードラベルスロット、その他の付加価値機能モジュール。

7.生産と納期の保証

- 生産能力の拡大:5320㎡の標準化された作業場には、全自動の型抜き機、高速の紙台紙ライン、品質検査室があり、1日の生産量は5万個で、50万~50万オーダーのフレキシブルな納品に対応しています。

- 品質管理システム:ISO9001品質認証とFSC環境認証を取得し、原材料の保管から完成品の出荷まで18の品質検査工程を実施し、製品の平面度誤差≤0.1mm、色差ΔE≤1.5を保証する。

- サービス対応:48時間の校正と15日間の大量生産サイクルを提供し、グローバルな物流追跡と破損した再発行のコミットメントをサポートします。

協力プロセス

- 要件確認:製品のサイズ、数量、デザイン案(AI/CDR形式)を提出すること;

- スキーム策定:3営業日以内に材料の選択、コスト予算、3Dレンダリングをフィードバックします;

- サンプル確認:物理的なサンプルは3-5日以内に配信されます;

- 大量生産:商品は契約締結後7~14日以内にお届けします。