You sell jewelry sets. You want the box to look premium, open smooth, and keep every tiny piece in place. Custom magnetic rigid boxes do all three, while keeping your brand cues tight across channels (DTC, wholesale, retail display). Below I’ll keep the language plain, add concrete tactics, and plug real-world use cases from China Custom Boxes Factory so you can brief your team fast.

Magnetic Closure Boxes: Why Jewelry Sets Love Them

Magnetic lids snap shut with a clean “click,” so the lid doesn’t wander during shipping or on-shelf handling. That one detail lifts the unboxing feel and reduces parts-loss on small items like studs and pendants. Your shopper opens it with one hand, no struggle; the set looks aligned and “ready to wear.” For deeper category context, browse our main page on Magnetic Closure Boxes.

Custom Magnetic Rigid Box for Jewelry Necklace

Necklaces tangle, rings roll, and bracelets scuff. A rigid board box with a magnetic flap + velvet or foam insert locks the set in place. If you need visual inspo, peek at glitter finish + necklace direction here: Custom Magnetic Closure Glitter Paper Box Jewelry Necklace. This finish isn’t only shiny—it photographs well for PDPs and socials.

Core Arguments (Evidence-Lite, Ops-Ready)

| Argument (H2-ready) | What it means in daily work | Where it helps most | Ops tip you can act on |

|---|---|---|---|

| Magnetic Closure Boxes improve open/close UX | One-tap open, self-locating close | DTC unboxing videos; retail tester areas | Add soft-close tolerance in dieline; check magnet polarity early |

| Custom Magnetic Rigid Boxes reduce product shift | Insert “nests” every piece | Multi-piece jewelry sets; travel kits | Mix slots: ring post + necklace notch + earring micro-cavities |

| Rigid Boxes increase perceived value | Stiffer board = more “gift feel” | Gifting peaks; premium lines | Pair with soft-touch film or linen paper to lower glare |

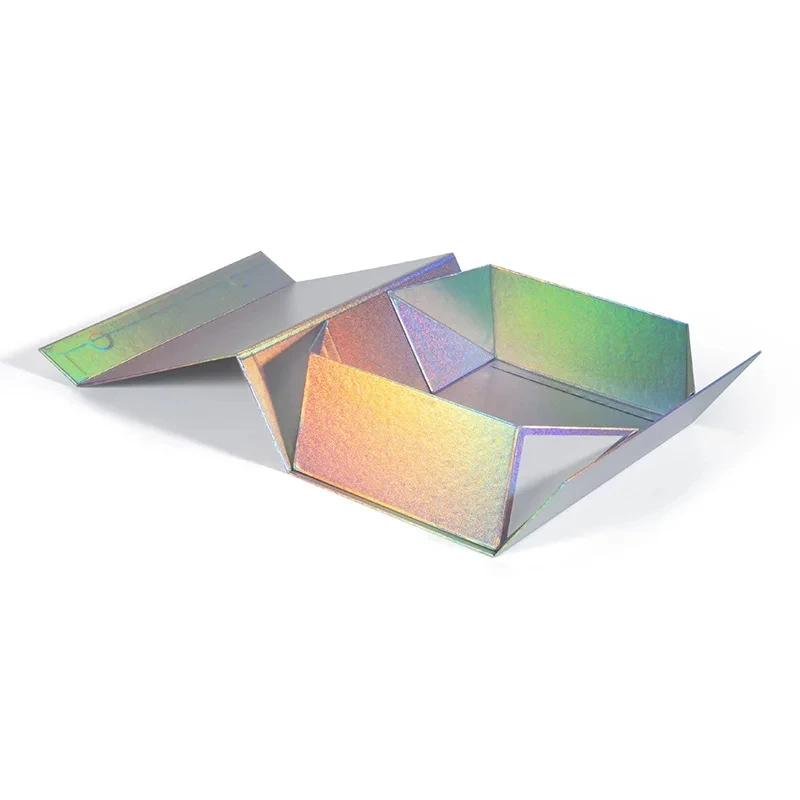

| Collapsible Magnetic Closure Boxes lower freight | Flat-ship to 3PL, pop-up at pack-out | Global drops; promo kits | Use spine creases + hidden magnets; sample the fold line |

| Magnetic Lid Boxes support brand systems | Print, foil, deboss, fabric inlay | Omnichannel brand kits | Lock color codes across SKUs for shelf blocking |

| Modular Inserts protect SKU count | Swap inserts for new assortments | Launch calendars; seasonal edits | “One shell, many inserts”—keeps tooling simple |

| Eco-tonality is possible | Uncoated papers, water-based glue | Natural or craft lines | Communicate finish expectations (less ink pop, more texture) |

Custom Magnetic Rigid Boxes for Jewelry Sets: Feature Stack

- Structure: hard board shell, wrap paper, magnetic flap.

- Insert options: velvet-lined tray, flocked foam, EVA with fabric top, paperboard platforms.

- Finishes: soft-touch, linen, glitter, matte lamination, foil stamp, spot UV.

- Brand elements: inside lid story panel, ribbon pull, certificate pocket, QR for authenticity.

- Compliance UX: tamper label area, transport drop test focus on hinge edge.

Why it matters: sets contain multiple fragile SKUs. Without a shaped insert, items crash into each other and micro-scratch in transit. With a shaped nest, your return rate drops and reviews go up (yep, even one star swing is huge on marketplaces).

Real Use Scenes (not just theory)

Magnetic Closure Cosmetic & Jewelry Crossovers

Cosmetics brands already use glitter paper and velvet linings to stage shine. That same visual logic sells jewelry. See texture & sparkle treatments here: Magnetic Closure Cosmetic Eyelash Glitter Paper Box Solution. Translate it to necklaces + earrings to build “gift set theater” under store lights.

Satin-Lined Magnetic Closure Boxes

Luxury hair and wig packaging proves satin elevates perceived softness and care. Jewelry can borrow that language for pearls and gold-plated pieces. Example direction: Satin Lined Magnetic Closure Box Wigs Hair Extension Online. Swap satin color to your palette, keep the drape.

Foldable Magnetic Gift Boxes (for freight sanity)

When your logistics team whispers “dim weight,” collapsible magnetic styles save volume. They flat-pack to your 3PL, then pop into shape at kitting. Here’s a similar structure pattern: Foldable Magnetic Cap Baseball Hat Gift Box Packaging Vendor. Different category, same idea.

Design Checklist (H3: practical keywords included)

Insert Design for Jewelry Sets

- Map the necklace drop, chain path, pendant cavity, and clasp park.

- Add earring posts and micro-wells for backings.

- Use ring slots with a squeeze-fit to stop rattle.

- Consider a removable tray so store staff can present fast.

- Run a shake test before sign-off—sounds simple, works.

Rigid Board & Wrap Paper Selection

- Go for stiff greyboard for the shell; avoid overly thin walls.

- Soft-touch lamination gives a warm feel; linen paper adds fiber texture; glitter wraps drive shelf pop (just be clear on glitter fallout control).

- If you push eco cues, choose uncoated kraft-look papers; expect muted color. That’s normal, don’t panic.

Magnetic Closure Tuning

- Hide magnets under wrap; keep hinge line crisp.

- Add thumb notch for single-hand open.

- Verify polarity and magnet strength with real inserts inside, not empty shells (different mass = different feel).

Branding & Info Architecture

- Lid top: minimal logo + foil.

- Inside lid: short story block, care card flap, QR for warranty.

- Base: product name + SKU + tiny barcode zone (retail needs it).

Use Cases by Channel (mini spec table)

| Channel | Box Type | Insert | Finish | Why this combo |

|---|---|---|---|---|

| DTC gifting | Magnetic Closure Boxes (non-collapsible) | Velvet tray + ring post | Soft-touch + gold foil | Feels luxe on unboxing videos, dust-safe |

| Wholesale trays | Custom Magnetic Rigid Boxes with removable try | Flocked foam | Linen wrap | Fast re-stock, grip-friendly |

| Pop-up events | Collapsible Magnetic | EVA + fabric top | Matte lamination | Ships flat, assembles quick |

| Travel retail | Slim magnetic lid | Paperboard platforms | Spot UV logo | Light weight, easy stack |

| Limited editions | Magnetic + ribbon pull | Satin bed | Glitter paper + foil | Eye candy, limited drop vibe |

Production & Ops (talking shop)

- Dieline discipline: lock insert first, then derive outer shell. Many teams do the opposite and end up tight on corners.

- Color control: run swatches on your actual wrap paper; soft-touch and uncoated substrates shift tones.

- Kitting flow: if you ship flat, train packers on magnet-side first assembly to avoid hinge stress.

- QA focus: check edge wrap, corner folds, magnet seat, and the “first open” force.

- MoQ & lead-time talk: speak early; we handle OEM/ODM and bulk wholesale, so we can balance promo calendars with steady runs. No, don’t overbuy dead SKUs.

Cross-Category Proof (cred adds trust)

If categories like lashes, perfume minis, or VIP kits thrive in magnetic-lid rigid boxes, jewelry sets will too. For texture-led inspiration, see lipstick set direction here: Purchase Luxury Lipstick Tube Gift Set Magnetic Lid Boxes. Translating that “gift theater” to gemstones is straightforward: adjust cavities, keep the shine.

Business Value (why finance will nod)

- Lower return risk: items arrive seated; fewer “damaged in transit” notes.

- Higher AOV: giftable packaging nudges add-to-cart on bundles.

- Brand equity: tactile finishes + clean close = premium signal.

- SKU rationalization: one outer shell, multiple inserts; new set = swap insert, not full retool.

- Channel harmony: same form works for online and storefront. That saves brain space.

btw, some clients run collab drops with influencers. They co-brand the lid foil and tuck a signed card under the tray. Sounds small, sells fast. LOVINHUG did a similar co-brand vibe last season—simple foil, big memory. It worked quite nice, even if sample timing was a bit tight.

How We Fit (China Custom Boxes Factory)

We’re a leading custom boxes manufacturer in China. We build Magnetic Closure Boxes, plus Lid and Base, Drawer Style, Collapsible Gift Boxes, Clamshell, Unusual Shaped, Paper Tube, Mailer, Folding Cartons, Child Resistant, and Paper Shopping Bags. OEM/ODM, bulk wholesale, private label—your procurement team, your distributor, or your contract manufacturer can all plug in. You bring the artwork and set BOM; we tune the dieline, materials, and finishing stack until it feels right.