You sell electronics in sets—device, cable, charger, maybe a VIP card or quick-start guide. You want the box to look premium, ship safe, and open smooth. That’s where magnetic closure boxes shine. Below, I’ll keep it practical: what works, what to watch for, and how to spec it with real-world constraints in mind.

Magnetic Closure Boxes for Electronics Bundles

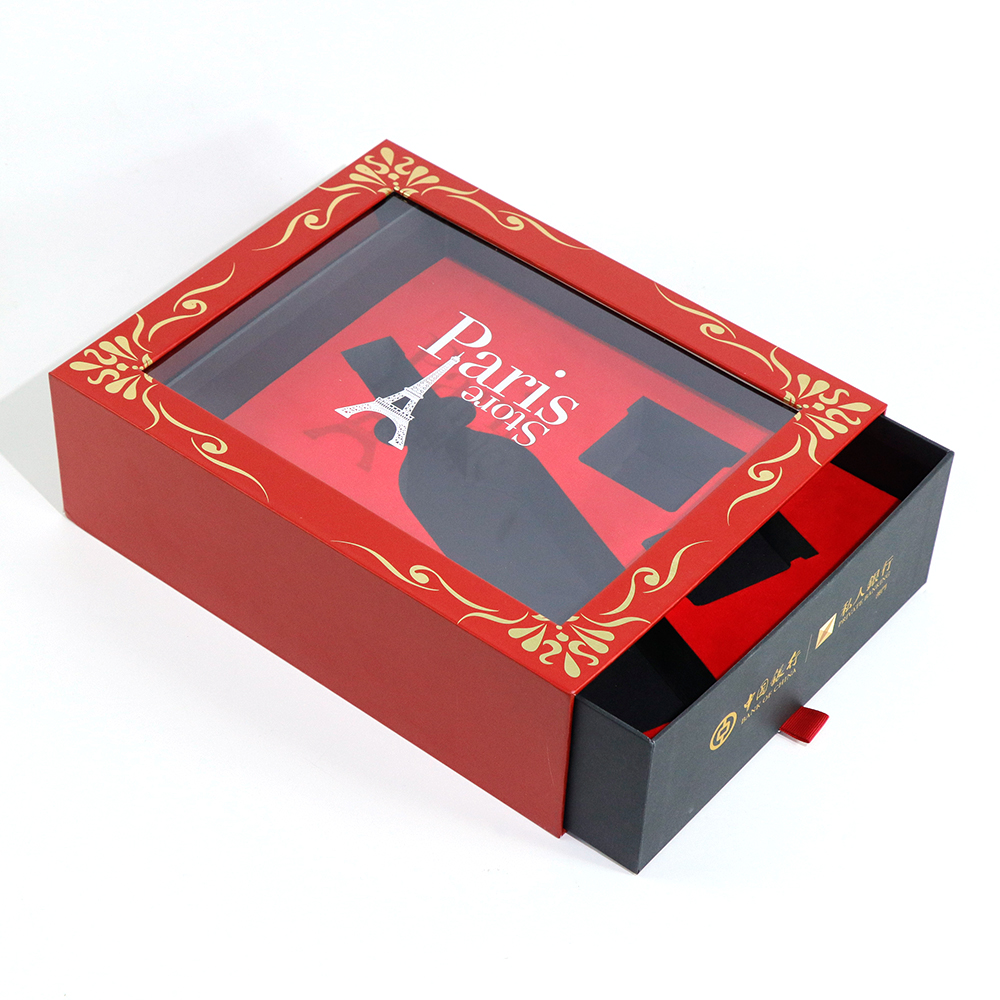

Magnetic lids add a clean “click” when the flap lands. It signals quality without shouting. For bundles, the lid helps two things at once: a tidy unboxing and a lower chance the box pops open in transit. Pair the magnet with a smart lock-up structure (book-style or clamshell) and you get both feel and function.

Want to see options? Start here: Magnetic Closure Boxes.

Rigid Magnetic Closure Boxes (Materials, Structure, Insert)

Rigid grayboard with wrapped paper gives you stiffness, flat panels, and tight edges. Add a custom insert to stop parts from rattling—EVA, molded paper pulp, or FSC paperboard. EVA is precise and durable; pulp is greener; die-cut board is cost-light and fast to adjust.

A tidy example with fitted insert: Magnetic Closure Scissors Boxes Packaging Solution with Eva. Same logic works for cameras, earbuds, hubs, or shavers.

Branding & Unboxing Experience (Premium Look Without Waste)

Keep print simple: soft-touch lamination, spot UV on the logo, restrained foil for the sub-brand. Use a reveal sequence—top card (hello + QR), device nest, then cables underneath. The lid should lift with one hand, close by itself as the magnet catches. It just works, even the lid don’t pop.

If you’re selling smart home kits, check: Custom Home Wireless Cam Security Camera Packaging Boxes.

Packaging Engineering: ISTA 1A/2A/3A Drop & Vibration Tests

Spec the experience, then prove it survives shipping. Use ISTA methods for bench validation:

- Drop: multi-edge, corner drops at defined heights.

- Random vibration: simulates truck/air freight.

- Compression: stacked pallet pressure.

- Climate: hot/cold/humidity cycles for glue and wrap stability.

Goal: lid stays shut, components don’t jump cavities, surfaces don’t scuff. If a pretty box fails, you tweak structure—not only add stronger magnets. More magnet isn’t always more safe.

Magnet Safety: Pacemaker and Card Stripe Guidance

Magnets are fine for most solid-state devices. Still, do the basics:

- Add a small warning for pacemakers/ICDs: keep a safe distance.

- Keep magnetic stripe cards, compasses, bare HDDs away from magnets.

- In the tray, place magnets on the side away from sensitive bits.

- Add a “soft close” felt or foam landing so the snap isn’t violent.

If your set includes a VIP card, this helps: Distributing Magnetic Lid Rigid Box For VIP Membership Card.

Sustainability: Recyclable Paper, Removable Magnets

Most recyclers prefer paper-only streams. So make the magnet removable:

- Machine a shallow channel; hold the magnet with an easy-peel label or pull tab.

- Print a tiny instruction: “Remove magnet before recycling.”

- Choose recycled paper where possible, water-based varnish, soy inks.

Want to keep the luxe feel while staying responsible? Use molded fiber trays, reduce void space, right-size the mailer.

Operations & Supply Chain (OEM/ODM, Bulk, Lead Time Savers)

You want speed-to-market and repeatability:

- DFM: round inner-corner radii, consistent wrap margins, glue stations that operators can run without rework.

- Kitting: color-code cavities, print compartment icons. Reduces pick errors on the line.

- Pallet Fit: design outer carton to hit sweet pallet counts; fewer mixed pallets = fewer damages.

- QC: lid-gap gauge, magnet pull-check jig, rub-test for inks, tape-peel for lamination.

- Forecasting: lock base structure, vary only wraps and inserts for variants.

Need an electronic-care example? See Direct Factory Magnetic Closure Box Oral Irrigator Packaging.

Use Cases: What Goes Into the Electronics Bundle

- Smart home kits: hub + sensors + cables + install card.

- Audio starter sets: earbuds + charger + tips + carry pouch.

- Personal care devices: shaver + heads + charger + brush.

- Portable power: power bank + USB-C + pouch + warranty.

- Camera accessories: action cam + mounts + battery + door.

If your catalog spans tech plus lifestyle, a foldable variant helps in storage. You can also borrow styling cues from cosmetics/luxury when it fits your brand voice.

Argument Table (What to Decide and Why)

| Argument / Pain Point | What it means in practice | Risk if ignored | What to spec |

|---|---|---|---|

| Magnet strength vs. openability | Magnet must hold in transit but open with one hand | Returns due to crushed edges or lids popping | Medium pull force + mechanical lock geometry |

| Structure before magnet | Design the fold + flap angle to “seat” the lid | Over-reliance on magnet, scuffs at the lip | Book-style or clamshell with landing ledge |

| Insert precision | Parts must not migrate during vibration | Rattles, scratches, warranty claims | EVA or molded pulp with tolerance stack-up review |

| ISTA validation | Run drop/vibration/climate as final pack | Pretty box that fails real logistics | Test at master-pack level with real weight |

| Safety labeling | Pacemaker and card-stripe notice | Customer complaints, safety escalation | Small icon + text under flap |

| Recyclability | Paper stream needs magnets removed | Box becomes “non-recyclable” in practice | Pull-tab magnet, micro-instruction print |

| Kitting efficiency | Easy load at factory line | Slow line, mis-picks, overtime | Cavity icons, color marks, tray numbering |

Spec Tips (Quick Wins You Can Copy-Paste Into RFQs)

- Board: rigid grayboard with wrapped art paper, edges tight to ≤1 mm visible board.

- Lamination: soft-touch or matte PP; add spot UV on logo if needed.

- Magnet: hidden neodymium, matched pair, medium pull; place away from card slots.

- Insert: EVA 45–50 shore A (or molded fiber), tolerance noted in drawing.

- Closure: “soft close” landing—thin felt strip or foam tape under flap.

- Print: CMYK + 1 spot; inside print for guidance graphics (setup map, icons).

- Cartonization: inner foam sheet on logo panel; master carton with corner protectors.

- Tests: run ISTA 1A/2A/3A appropriate to your ship mode; sign off with photos + report.

Why China Custom Boxes Factory (and LOVINHUG)

You need a partner who can design, tool, and mass-produce without 12 rounds of back-and-forth. China Custom Boxes Factory handles OEM/ODM, bulk, and private-label specs for Magnetic Closure Boxes, Lid & Base, Drawer Style, Collapsible Gift Boxes, Clamshell, Paper Tube, Mailer Boxes, Folding Cartons, Child Resistant Packaging, and more. We already build for lifestyle and beauty—those finishing standards translate well to electronics sets. LOVINHUG and other brands choose consistent wrap quality, tight corners, and inserts that actually fit.

When you want glam plus guardrails—smart graphics, sturdy structure, clear safety—this is the box that does the job.