You don’t just sell donuts—you sell that first glance. The box is the mini-billboard, the freshness vault, and the shareable moment on a desk or feed. Below is a practical, maker-friendly guide to custom donut boxes that look good, ship flat, stack neat, and meet food safety. I’ll keep it plain, fast, and focused on ROI you can feel in-store.

Donut Packaging Materials: Food-Grade Paperboard, Grease Barrier, No-Added PFAS

If the box fails, the glaze tells on you. Go with food-grade paperboard, a reliable grease barrier, and no-added PFAS coatings. Ask for FSC sources when you need sustainability claims. Paperboard keeps structure, prevents sag, and prints clean with CMYK or spot colors.

CMYK Printing, Pantone Color Matching, Water-Based Inks

Brand colors need to hold under bakery lighting. Use CMYK for photos and Pantone for lock-tight brand hues. Water-based inks support food contact and keep odor low. It’s not magic, just spec discipline.

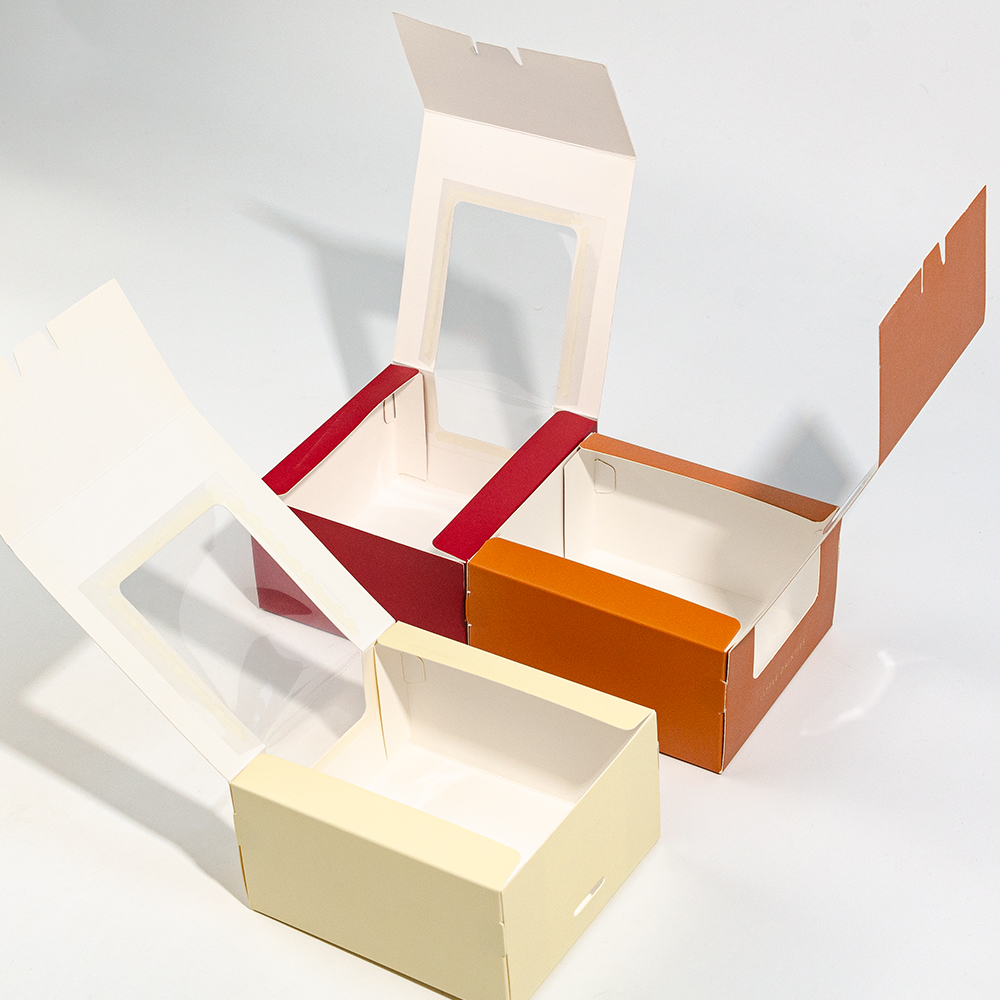

Window Donut Box & Stackable Design: See-Through Sells

A clear die-cut window lets customers “taste with eyes.” Pair it with stackable design and reinforced folds so staff can build vertical displays without crush. Single, 6-pack, and 12-pack formats cover most café runs and office drops.

Folding Cartons for Donuts (Retail-Ready)

Most donut programs live on folding cartons—they ship flat, set up fast, and cut your back-of-house friction. If you need a sturdier unboxing, explore lid and base or drawer style structures for gifting.

- Browse structures by shape: Boxes by Shapes

- Explore sectors: Boxes By Industries

Color Psychology in Donut Packaging: Warm Tones, Flavor Cues, Seasonal Drops

Warm pinks, corals, and soft reds shout “fresh and sweet.” Greens telegraph matcha or pistachio. Keep flavor cues on-box—people map color to taste, fast. Seasonal sleeves (Valentine, Halloween) move units without re-tooling the main die.

Artwork Setup: High-Res, Bleeds, Quiet Zone

Keep 300 dpi, add bleed, and protect a quiet zone around logos. Avoid tiny type on coated boards; ink gain is real. Ask prepress for a digital proof and a hard proof if you’re picky on hue.

Sustainability & Compliance: FSC, Recyclable, Food Contact Declarations

Buyers want receipts. Document FSC chain of custody, recyclability info, and food contact declarations. Add small icons near the tuck flap. Make it easy for staff and customers to do the right thing—less question, more trust.

- Gift-forward formats: Collapsible Gift Boxes

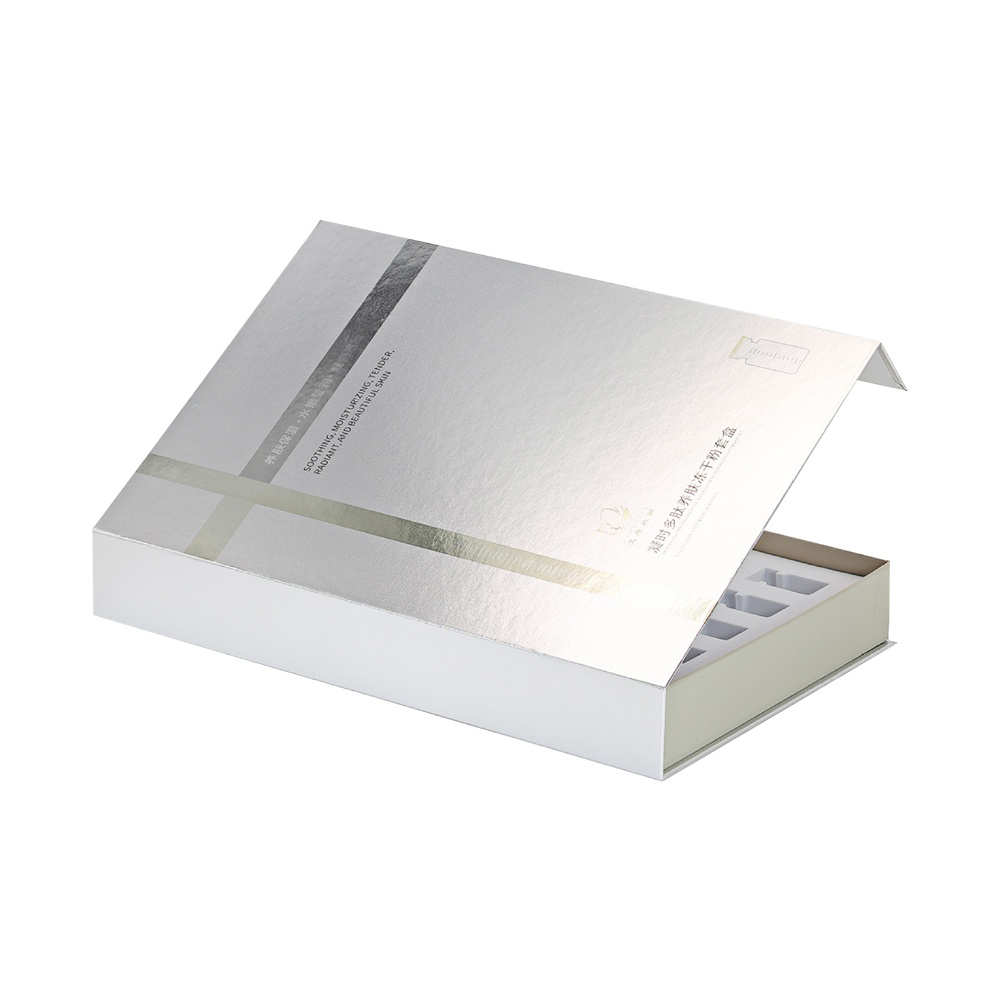

- Premium unbox: Magnetic Closure Boxes

Structural Options: Lid and Base, Drawer Style, Clamshell, Mailer

Different channels, different needs.

- Lid and Base Boxes: premium assortments, influencer sends.

- Drawer Style Boxes: tidy reveal; protects toppings in transit.

- Clamshell Boxes: speed at the counter, single-serve.

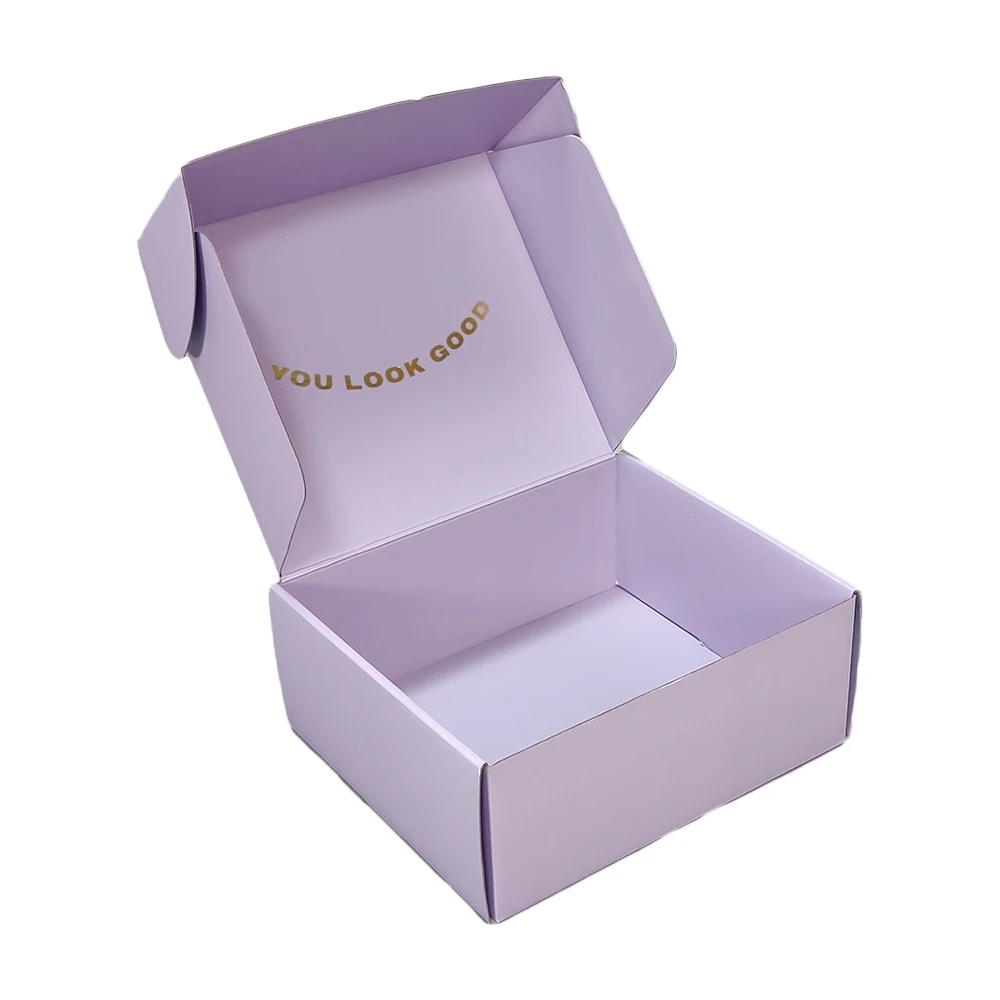

- Mailer Boxes: e-comm sampler packs with inserts and vents.

Need odd shapes for a collab SKU? See Unusual Shaped Boxes—great for novelty rings or mini stacks.

Operations & Cost Layers (No Numbers, Just Logic)

- Short runs: digital print, fast art swaps for events.

- Standard runs: offset print, spot colors for consistency.

- Finishes: soft-touch film, matte/gloss varnish, foil, or blind emboss for tactile “stop.”

- Inserts: keep donuts from skating; fewer damages, fewer refunds.

- Ship flat: reduces warehouse load, keeps pick/pack simple.

Real-World Scenarios: Café, Catering, e-Commerce

Café counter You need one-hand setup, stack-safe, and windowed lids. Staff shouldn’t fight the crease. Punchy colors plus a flavor sticker = faster turns.

Corporate catering Order arrives early, sits in a break room. Go for extra board caliper, easy lift tabs, and a small QR for allergen info. No smudge inks. No mystery lids.

E-commerce sampler Mailer + insert + vent punches. Outer branding stays clean; inner panel gets the party line and social handle. Include a mini paper shopping bag for gifting—yes, folks still love a hand-off.

- Add-on carry: Paper Shopping Bags

- Classic retail workhorse: Folding Cartons

Brand Story On-Box: QR Codes, UGC, and Flavor Mapping

Print a tiny flavor map, a QR to behind-the-scenes bakes, and a UGC nudge. Keep it human: “Got crumbs? We do too.” People share honest packaging that talks like a person. Little grammar not perfect? It’s fine, feels real.

Table: Claims, Why It Matters, Practical Spec, ChinaCustomBoxes Fit

| Claim | Why it matters | Practical spec/option | ChinaCustomBoxes fit |

|---|---|---|---|

| Food-grade paperboard | Protects texture, avoids off-taste | Board with grease barrier, no-added PFAS | Material sourcing + compliance docs |

| Window donut box | “Eye bite” drives impulse | PET/PLA window, die-cut shape, anti-fog optional | Custom dies, fast setup, clean fold lines |

| Stackable design | Safe displays, fewer dents | Reinforced panels, lock tabs | CAD-tested dielines for vertical load |

| CMYK + Pantone | True color under shop lights | CMYK for images, spot for brand hues | Color management, hard proofs if needed |

| Seasonal sleeves | Fast refresh, low tooling | Short-run digital, belly band | Split runs, quick art swaps |

| FSC + recycling icons | Clear green claims | On-box icons + QR to policy | Printed compliance + FSC chain |

| Inserts & vents | Topping protection, less steam | Paperboard grid, micro vents | Die-cut inserts matched to SKUs |

| Flat shipping | Lower storage pain | Knockdown, quick erect | Pack counts tuned to pick/pack |

Pain Points We Fix (Procurement Speak, but friendly)

- Color drift between batches → we lock spot colors, verify on calibrated proofs.

- Warping in humid kitchens → pick board caliper and finish for your climate.

- Window haze → specify film type and anti-fog where needed.

- Slow kitting → ship flat with clear crease memory; staff can fold blindfold (ok… almost).

- Sustainability audits → FSC docs, food contact letters, and recycling marks ready.

Why ChinaCustomBoxes

China Custom Boxes Factory builds donut packaging at scale with real OEM/ODM muscle—magnetic closure boxes, lid and base boxes, drawer style boxes, collapsible gift boxes, clamshell boxes, unusual shaped boxes, paper tube boxes, mailer boxes, folding cartons, child resistant packaging, and paper shopping bags. We support enterprise buyers, distributors, private-label teams, and startups who need repeatable quality, not drama. You bring the brand; we bring the dieline, prepress, and a production floor that actually picks up the phone.