If you sell beauty, wine, or electronics, you know packaging isn’t just a box. It’s a handshake. UV coating can make that handshake feel firm, glossy, and premium—and sometimes a bit too slick. Below I break down what UV coating really does, where it shines, where it bites, and how brands working with China Custom Boxes Factory can use it smart across Boxes by Shapes and Boxes by Industries.

What Is UV Coating in Printing?

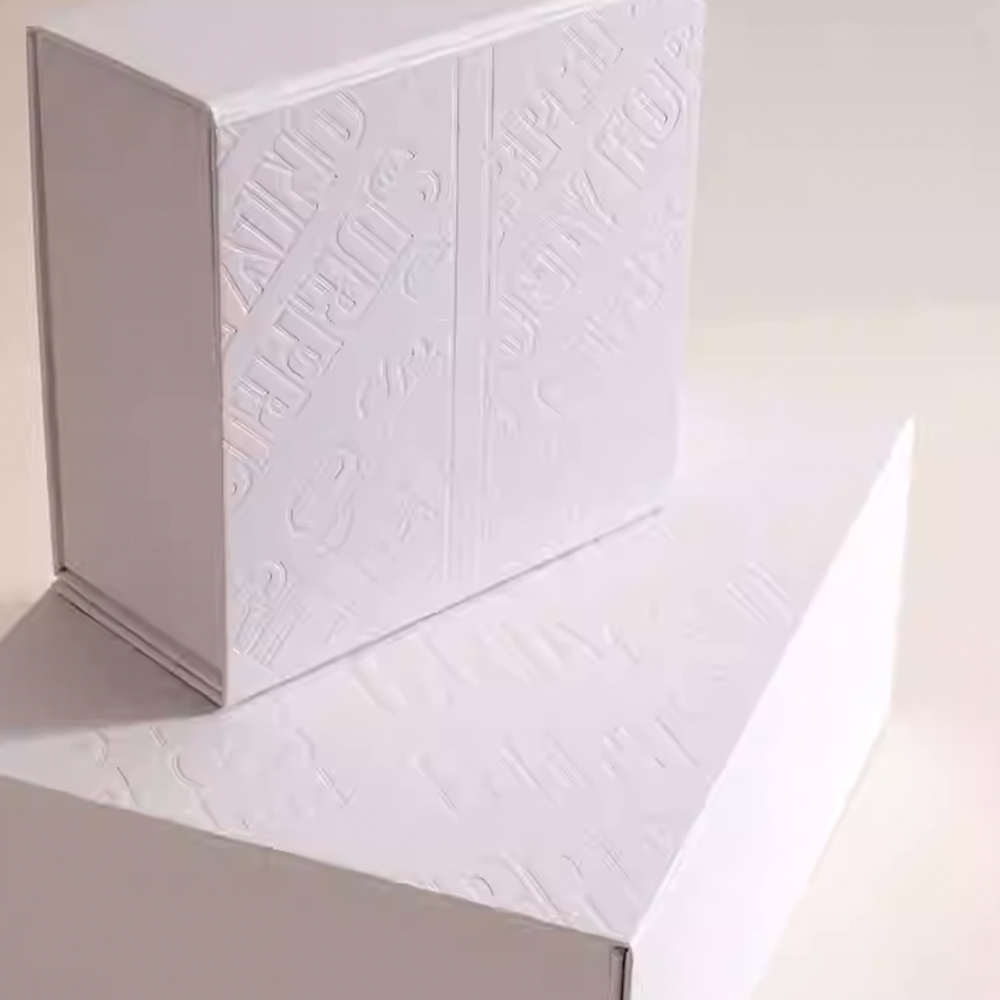

UV coating is a clear liquid finish cured under ultraviolet light. It sits on top of your print layer and creates a high-gloss or satin shield. You’ll see it on cosmetic cartons, rigid boxes, catalogs, and luxury gift packs. In short: fast cure, strong pop, better scuff resistance. But it isn’t magic—there are trade-offs.

Benefits of UV Coating (Printing & Packaging)

- High Gloss and Color Pop. UV increases saturation, especially on deep blues, reds, and blacks. Images look richer. Logos lift.

- Surface Protection. Better scratch, rub, and fingerprint resistance than standard aqueous varnish.

- Fast Turnaround. UV cures almost instantly, so jobs move through finishing quicker.

- Selective Finishes. Spot UV lets you highlight logos, patterns, or typography without coating the whole panel.

- Brand Perception. Premium shine equals premium feel—ideal for gifting and display packaging.

Drawbacks of UV Coating (What to Watch)

- Folding & Cracking Risk. The cured film is harder. At scores and folds, it may crack if the stock, caliper, or creasing profile isn’t right.

- Poor Write/Stamp Ability. Pens, stamps, and some labels don’t stick well on glossy UV.

- Adhesion on Digital Toner. Toner-heavy digital prints can lower surface energy, so UV may not bond—test with your actual ink set.

- Glare and Fingerprints. High gloss can reflect light and show smudges on large flat areas.

- Design Constraints. Ultra-fine spot UV needs tight registration and clean dielines; micro text can look messy if you overdo it.

Spot UV vs Overall UV Coating (Keyword: “Spot UV Printing”)

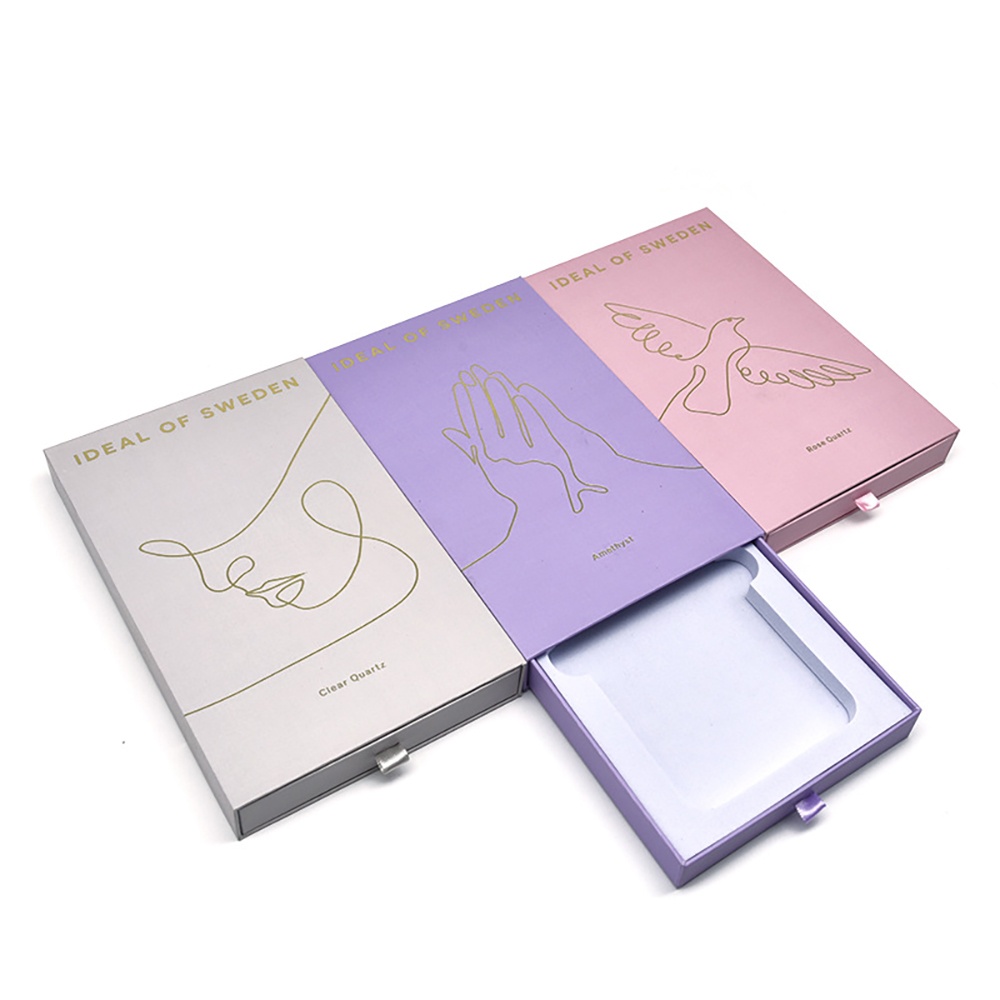

- Spot UV Printing: Targeted gloss on specific elements (logos, gradients, texture patterns). Use it to create contrast on matte stocks or soft-touch laminate.

- Overall UV Coating: Full-panel coating for maximum shine and protection on covers, sleeves, and lids. Great when you want a uniform, mirror-like surface.

UV Coating vs Aqueous Varnish vs Lamination

| Finish Type | Gloss/Sheen | Flex for Folds | Scuff Resistance | Printability (Write/Stamp) | Typical Use |

|---|---|---|---|---|---|

| UV Coating | High–Very High | Medium–Low (risk at scores) | High | Low | Premium cartons, rigid box lids, gift sleeves |

| Aqueous Varnish | Medium | High | Medium | Medium | Brochures, folding leaflets, inside panels |

| Lamination (Gloss/Matte/Soft-Touch) | Medium–High | High | Very High | Low–Medium | Luxury rigid boxes, e-comm shippers, display trays |

Quick tip: If you need deep folds (multi-crease mailers or tight sleeves), aqueous or lamination may beat UV on crack-free performance.

Best Use Cases in Packaging

- Cosmetic Packaging Boxes. Spot UV over a matte base makes a logo feel embossed without tooling. Great for gradient patterns and foiled marks.

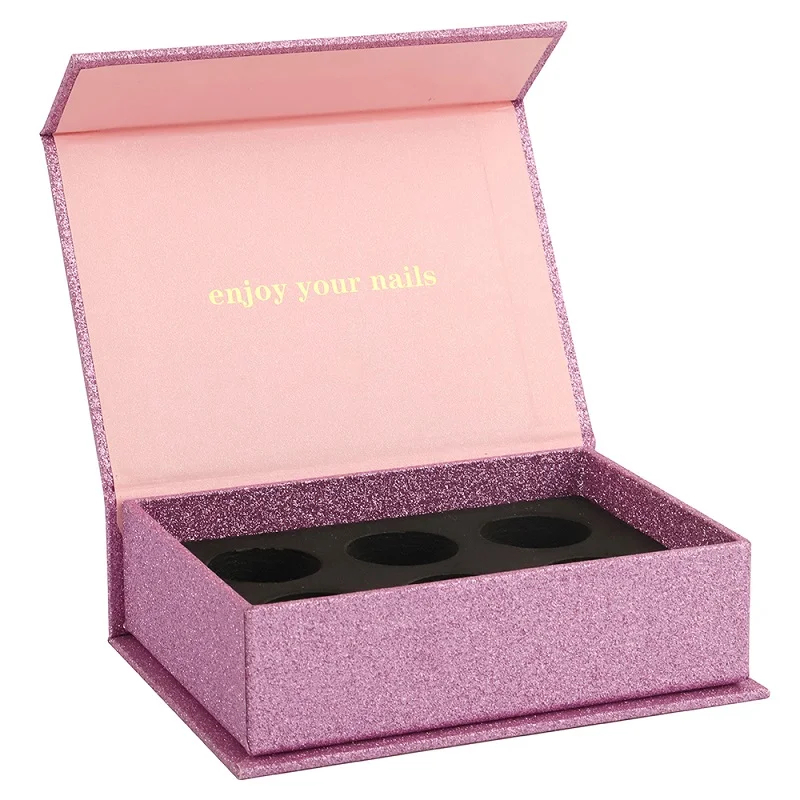

- Magnetic Closure Boxes — add overall UV to exteriors for bold shine, then use soft-touch lamination on the inner cradle for tactile contrast. Explore: Magnetic Closure Boxes.

- Folding Cartons — use aqueous inside for fold performance, and spot UV outside to highlight brand elements. See: Folding Cartons.

- Paper Tube Boxes — UV bands around the canister create a “360° gloss ring” effect.

- Promotion & Gift Boxes — pair soft-touch lamination with spot UV to hit that “matte vs gloss” look. Browse: Promotion & Gift Boxes.

- Paper Shopping Bags — use spot UV on front panels to lift logos while keeping handles and gussets matte for grip. Check: Paper Shopping Bags.

Industry-Grade Tips for UV Coated Packaging

- Score Smart. Specify channel width and depth based on board caliper. Ask for pre-score tests to avoid cracking on UV-heavy areas.

- Leave Write Zones. If you need batch codes or hand-written notes, leave a no-UV rectangle or switch to matte laminate in that area.

- Mind the Toner. For short-run digital, request adhesion tests (cross-hatch or tape pull). If it fails, pivot to aqueous or laminate.

- Registration Discipline. Keep spot UV at least 1.5–3 mm from trim and folds. Tight trapping avoids “halo” edges.

- PMS & Substrate. UV intensifies perceived color. Confirm PMS on your actual substrate; uncoated vs coated paper behaves different.

- QC & Cartonization. High-gloss surfaces scuff in transit. Use interleaving, right K-A fluting for shippers, and don’t overpack.

When Not to Use UV Coating

- Writable or Stampable Areas. Loyalty cards, gift notes, regulatory stamps—UV will fight you.

- Heavy Fold Architectures. Complex multi-panel drawer style boxes and tight gussets want flexible finishes.

- Low-Glare Requirements. Retail lights or studio LEDs can cause glare. Matte or soft-touch finishes read cleaner on camera.

Sustainability Notes for UV Curing

UV coatings are often billed as low-VOC during cure and they can be compatible with standard paper recycling streams, depending on local MRF practices. Still, they’re a polymer film and wont biodegrade quick. If your brand leans Eco, consider: aqueous inside panels, spot UV only on brand marks, or matte/soft-touch laminate with recycled boards. Always align with your region’s recycling guidance.

Real-World Scenarios

- Perfume launch with tight ship date. Use overall UV on rigid lid panels for punchy color, aqueous inside for fold, and spot UV on logo. ChinaCustomBoxes can run OEM/ODM with bulk order QC, PMS matching, and dieline tweaks to keep the crease clean.

- E-Commerce Packaging for fragile glassware. Laminate the mailer for durability, add spot UV badges to front-panel claims. Inside print stays aqueous for speed and cost control.

- Promotion roll-out for holiday gifting. Mix Collapsible Gift Boxes with spot UV snow-pattern over matte surfaces, so you get flat-pack shipping + premium look. See: Collapsible Gift Boxes.

Product Fit Matrix (Keyword: “Packaging finish selection”)

| Product Type | Finish Recommendation | Rationale |

|---|---|---|

| Cosmetic Packaging Boxes | Matte/soft-touch + spot UV | Luxury contrast, fingerprint control |

| Magnetic Closure Boxes | Overall UV exterior + matte interior | High shelf impact, tactile balance |

| Folding Cartons | Aqueous overall + selective spot UV | Fold reliability, brand highlights |

| Paper Tube Boxes | Band spot UV + matte body | 360° brand pop without glare |

| Promotion & Gift Boxes | Soft-touch + heavy spot UV | Gift feel, premium perception |

| Paper Shopping Bags | Spot UV logo only | Grip and low glare on sides |

Why China Custom Boxes Factory

You need a partner who can read dielines, speak pressroom, and fix issues before they hit retail. China Custom Boxes Factory supports OEM/ODM, bulk wholesale, and brand teams with rigid paper boxes, folding cartons, paper tube boxes, and paper gift bags at a good price point. We handle PMS color control, substrate sourcing, mock up, and transit tests—so your boxes don’t just look glossy, they survive freight and shelves.