You want boxes that fit your product and pass the carrier checks. Do both right, and you cut damage risk, avoid oversize surcharges, and ship smoother. Let’s walk thru it—plain talk, shop-floor style.

Internal Dimensions vs External Dimensions (Box Sizing Basics)

- Internal dimensions (ID) are for product fit when you’re making or choosing the box. Use ID for inserts, trays, foam, and “will it fit?” math.

- External dimensions (OD) are for shipping. Carriers measure the outside at the most bulged points. That’s what hits volumetric rules.

At China Custom Boxes Factory, we spec by L × W × H and default to ID for structural design—then we predict OD from board caliper. If you need special structures (like magnets or thick foam), tell us early so OD doesn’t creep.

Quick memory hook: Make with ID. Ship with OD.

How to Measure Length, Width, Height (Measurement Order)

The industry order matters:

- Length = the longest opening side.

- Width = the shorter opening side.

- Height (Depth) = vertical, from opening down.

Keep the sequence consistent in drawings, POs, and spec sheets. If you flip W/L, somebody will die (kidding, but your insert won’t fit).

Dimensional Weight (DIM Weight) for Shipping

Carriers charge by actual weight or dimensional weight (volumetric)—whichever is higher. Basic idea: bigger boxes “eat” more cargo space, even if they’re light.

Formula you’ll hear everywhere

- DIM (imperial): ( \text{DIM} = \frac{L \times W \times H}{\text{factor}} ) in lb

- DIM (metric): ( \text{DIM} = \frac{L \times W \times H}{\text{factor}} ) in kg Typical factors are widely used in the market. Check your carrier service before booking.

Workflow tip: round each side per the carrier rule (nearest whole unit or next unit up), then compute DIM. It’s boring, but it saves remeasure fees.

Length and Girth Limits (Oversize Controls)

Many services cap Length + Girth.

- Girth = ( 2 \times (W + H) ).

- If Length + Girth passes the limit for your lane/service, you’ll hit oversize handling or not accepted. Always check your service level’s cap before you pick the box style.

Tolerances, Caliper, and Board Thickness (Why OD Gets Bigger)

Paperboard has caliper (thickness), and corrugated has flute profiles. Add them and OD grows beyond ID.

- Common notes: ±1–3 mm tolerance on finished size is normal.

- Add extra space for wraps like paper over rigid board, or liners.

- Hinges, magnetic closures, ribbons, EVA foam, and molded pulp all push OD.

Building Magnetic Closure Boxes? The magnet seat and wrapped board can add small but real OD. If that’s your SKU, peek our line for structure options: Magnetic Closure Boxes.

Tools and Workflow (From Fit Check to Booking)

- Tape measure for OD, calipers for board thickness, square for right angles.

- Flat sample (KDF) to check panel sizes; 3D prototype for final fit.

- Weigh scale for actual weight; don’t guess.

- Spec sheet with ID/OD, tolerances, and insert callouts. Keep it single-source-of-truth.

Simple workflow

- Define product fit (ID).

- Choose box style + board.

- Predict OD from caliper and wraps.

- Mockup → adjust.

- Confirm OD and weight → check DIM + Length/Girth.

- Book carrier using the rounded OD rules.

Real-World Scenarios by Box Style (Practical Use Cases)

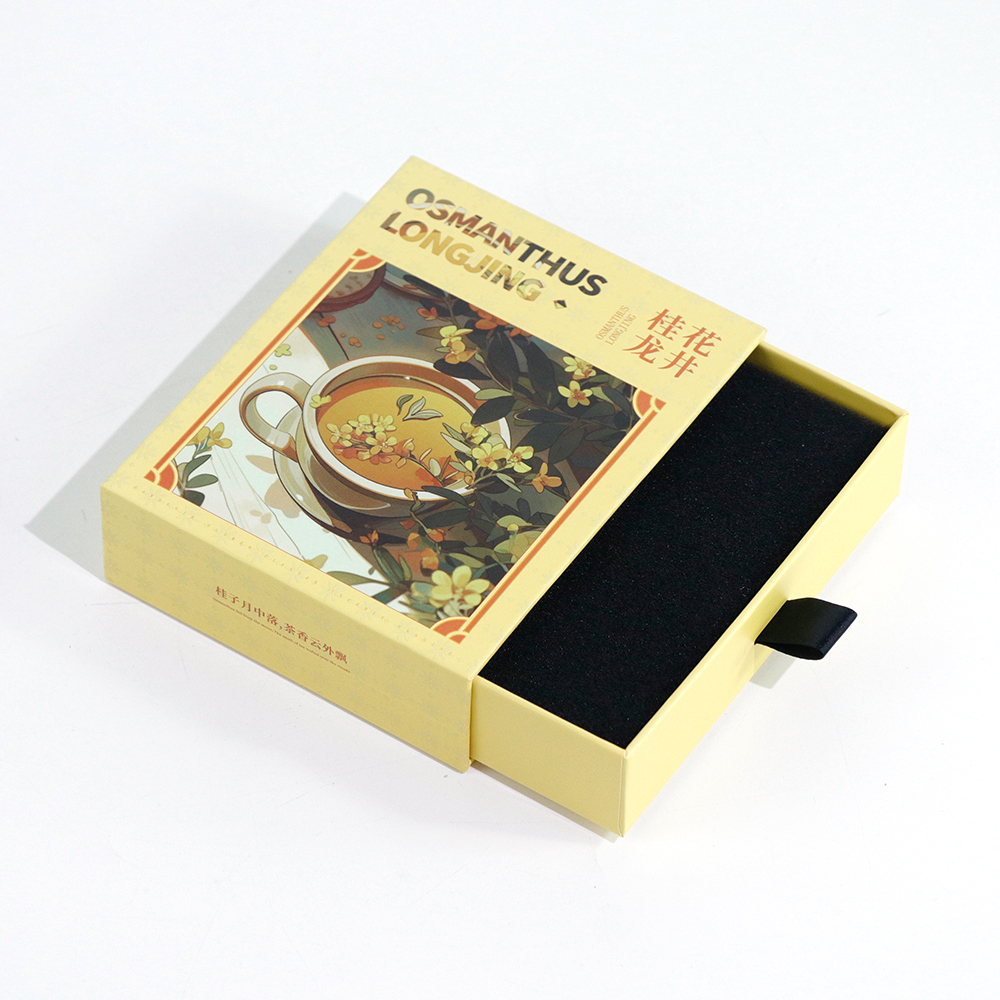

Rigid Gift Packaging (Magnetic, Lid-and-Base, Drawer)

- Risk: tight lids + thick wrap = OD creep → DIM jumps.

- Fix: design inserts to control bulge; add lid clearance.

- Explore styles: Lid and Base Boxes, Drawer Style Boxes, and Collapsible Gift Boxes if you need flat shipping to warehouses.

E-Commerce Mailers and Folding Cartons

- Risk: large “air” around small goods → you pay DIM.

- Fix: right-size with Mailer Boxes or Folding Cartons plus smart void fill.

- Browse families: Mailer Boxes and Folding Cartons (oops, cartons—see? real people typo).

- For DTC, your keywords are cube efficiency, pick & pack speed, tapeless close, KDF count.

Unusual or Cylindrical Shapes

- Risk: carriers measure the largest points. A hex tube? They’ll span the widest flat-to-flat.

- Fix: lock the OD with sleeves or end caps.

- See: Unusual Shaped Boxes and Paper Tube Boxes (cylinders) on our site.

Regulated Goods (Child-Resistant, Cosmetics, Cannabis)

- Risk: CR mechanisms and thick trays add OD, and inserts can bite height.

- Fix: lock the ID early; pressure test the closure; leave tolerance.

- Start here: Child Resistant Packaging and Cosmetic Packaging Boxes on our catalog.

Quick Reference Table (Making vs Shipping)

| Use Case | Which Size to Use | How to Measure | Rounding Rule (typical) | What to Watch |

|---|---|---|---|---|

| Design / Production | Internal (ID) | L = longest opening side; W = shorter opening side; H = vertical | Keep 0.1–1 mm precision for CAD; note tolerance | Inserts, foam, wrap, hinge, magnet seats add space |

| Freight / Courier | External (OD) | Measure at most bulged points; keep L × W × H order | Round per carrier before DIM calc | DIM weight vs actual weight; oversize limits |

| Compliance | OD + Girth | Girth = 2 × (W + H) | Round to whole units | Check Length + Girth cap for your service |

Worked Example (No costs, just logic)

Say your finished OD (after wrap and magnet) is 40 × 30 × 20 cm. You weigh the filled box and get the actual weight. Now:

- Round each side to the carrier’s unit (some round, some bump up).

- Compute DIM with the published factor for your lane.

- Compare DIM vs actual weight. The higher one rules the chargeable weight.

- Check Length + Girth: Girth = 2 × (30 + 20) = 100 cm; Length + Girth = 140 cm. Confirm it fits your service cap before you book.

Dont over-think it tho—what matters is picking the right style early so OD stays in check.

Pre-Ship Checklist (Copy/Paste this)

- ID confirmed on drawing with L × W × H.

- OD predicted from caliper + wrap; prototype verified.

- Rounding rules applied to OD.

- DIM vs actual weight compared.

- Length + Girth checked against service cap.

- Insert, foam, bottle shoulder, pump, cap, and safety cap heights included.

- For return flows (D2C), add room for RMA label or extra tape.

Where China Custom Boxes Fits In (Value without fluff)

- We customize Magnetic Closure, Lid and Base, Drawer, Collapsible, Mailer, Paper Tube, Folding Carton, and more.

- We support OEM/ODM, wholesale, and multi-SKU programs for perfume, beauty, cannabis, wine & spirits, gourmet, apparel, electronics, and e-commerce.

- Share your ID target, insert plan, and lane (air/ground/parcel). We’ll engineer for fit, cube, and compliance—from sample to mass run.

- Browse by structure or vertical to speed your spec: Boxes by Shapes and Boxes By Industries.

Glossary You’ll Actually Use

- ID/OD: inside vs outside size.

- DIM Weight: volumetric weight used by carriers.

- Girth: 2 × (W + H).

- Caliper: board thickness.

- KDF: knock-down flat, shipped unfolded.

- ECT/Burst: corrugated strength ratings; talk to us if you need a number for your lane.

- Oversize surcharge: fee when you exceed limits (avoid it).