You want packaging that shows the product, protects it, and moves fast from line to shelf. Custom die cut boxes do that. They trim to your product’s shape, add clear windows, and lock without tape. Below is a plain-spoken guide with real keywords, practical scenarios, and quick wins you can ship.

Custom Die Cut Boxes

Die cutting lets us match your product’s outline—bottles, droppers, jars, gadgets—so the item sits snug and visible. You cut material waste, reduce void fill, and get a clean face for printing. For buyers, it looks “made for me,” which build trust fast. At China Custom Boxes Factory (ChinaCustomBoxes), we run OEM/ODM and bulk wholesale for brands and distributors who need consistency across SKUs.

Custom Die Cut Inserts

Pair the outer box with a die cut insert in the same board, or mix foam/pulp when needed. The insert locks the object, stops rattle, and centers the hero on unboxing. It just work, even when couriers throw boxes around (they do).

Die Cut Window Packaging

A window shows color, texture, or craftsmanship. Shoppers touch with their eyes before they pay. Add PET or go window-without-film for plastic-free goals. Pro tip: echo the silhouette of your product in the window outline—recognition jumps.

- See shape options here: Boxes by Shapes

Self-Locking Die Cut Structure

Self-locking tabs speed kitting. Your team folds, tucks, clicks—done. No tape haze, no glue strings, less labor minutes. In DTC, this is throughput. In retail, it’s a cleaner seam so graphics pop.

Quick Line SOP

- Pre-crease blanks.

- Fold panels, engage locks.

- Drop insert + product.

- Close, QC shake test, palletize.

Rigid Boxes and Folding Cartons

Rigid (setup) boxes scream premium and stay square. Folding cartons ride flat and save freight. Both accept die cut windows, thumb notches, and custom closures. If you sell fragrances, jewelry, or electronics, combine rigid bases with precision die cut trays for that “lift the lid—there it is” moment.

- Explore premium closures: Magnetic Closure Boxes

Unboxing Experience

People film unboxing. Make it intentional: a reveal angle, layered messaging, tactile stock, and a small “hello” card nest under the lid. Don’t overload. Let one focal element lead—cap color, glass facet, or logo seal. That’s the thumb-stop on social.

Boxes by Industries

Different sectors have different stressors. Here’s how die cut formats map to common pain points.

- Cosmetics & Perfume: small bottles, leak-risk, strict alignment. Use friction-fit neck cutouts and shoulder catches.

- Candle & Glassware: weight plus fragility. Use cross-brace inserts and bottom locks to resist drop energy.

- Consumer Electronics: cable chaos, accessory scatter. Use tiered cavities and peel-back compartments.

- E-Commerce: faster pick-pack. Use self-lock mailers with return-ready lids.

Browse sectors: Boxes by Industries

Child Resistant Packaging

If you’re in cannabis or CBD, compliance matters. Combine die cut panels with CR features (push-and-turn, tear-off bands, locking sleeves). You keep the “fancy demonstration” up front, but you meet the rulebook on the back end.

- For regulated SKUs: Child Resistant Packaging

Paper Tube Boxes

Paper tubes are round, rigid, and photogenic. A top window or side cutout lets color and texture breathe. Add a die cut cradle inside to hold vials or mini atomizers so they don’t spin. Works great for minis and discovery kits.

Mailer Boxes

For subscription kits and DTC drops, die cut mailers carry the product and serve as the stage. Print the inside. Add thumb-cuts for easy lift. Keep flaps short so phones catch the reveal cleanly.

- Ship-ready shells: Mailer Boxes

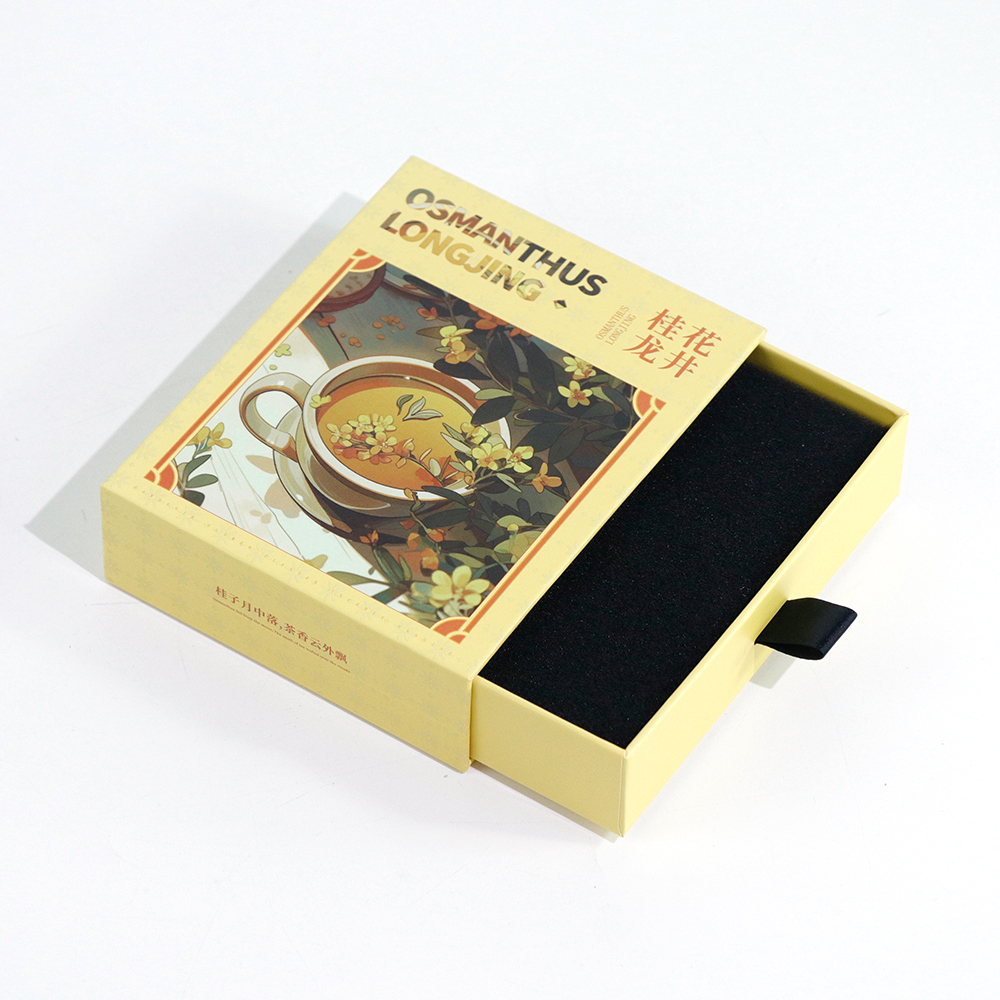

Drawer Style Boxes

A sleeve with a pull-out tray is inherently “fancy demonstration.” Die cut the tray to suspend the item, then notch the sleeve for grip. Add a fabric pull if you want that jewelry-store cue. Smooth friction equals perceived value.

Folding Cartons

When you scale retail, folding cartons take over. Lock-bottom, crash-bottom, or auto-bottom (industry shorthand you’ll hear on the line). Die cut windows and tabs make the pack self-explanatory at shelf and fast on the line.

- Retail workhorse: Folding Cartons

Argument–Evidence–Use Cases (Table)

| Argument (What) | Evidence (Why it works) | Use Cases (Where) |

|---|---|---|

| Tight fit reduces damage | Less movement = less impact energy; insert holds COG centered | Perfume flacons, candle jars, glass droppers |

| Window boosts shelf stop | Seeing texture/color increases trust and dwell time | Skincare sets, gourmet treats, small electronics |

| Self-lock saves labor | No tape/glue; fewer steps per unit | DTC kitting, flash sales, pop-up restocks |

| Rigid + die cut = premium | Sharp edges + precise cavity feel high-end | Jewelry, watches, collector editions |

| Drawer tray stages product | Controlled reveal cues quality | Gift sets, influencer kits |

| Tube with cradle stops spin | Internal cradle prevents rotation and scuff | Mini kits, lab vials, sample packs |

| CR mechanisms ensure safety | Meets regulatory pull/torque tests | Cannabis, CBD, pharma-adjacent SKUs |

Cosmetic Packaging Boxes

Fragrance and skincare buyers are visual. Use die cut windows to reveal glass clarity and tint. Add spot UV on brand marks, emboss on the line name, and a soft-touch film outside to reduce glare. Keep copy short. Let color speak.

(If you need category depth for beauty, see: Cosmetic Packaging Boxes)

Unusual Shaped Boxes

Odd geometry is memorable, but it must still stack and ship. We prototype unusual shapes with flat-sheet thinking first, then test friction points and panel strength. If it stacks, it sells.

- Creative silhouettes: Unusual Shaped Boxes

Collapsible Gift Boxes

For seasonal spikes, collapsible (knock-down) rigid boxes store flat and pop up on demand. Add hidden magnets or ribbon locks. Die cut windows maintain visibility without new tooling every season.

Lid and Base Boxes

A classic two-piece gives a museum-style reveal. Die cut a platform that lifts the item, angle it 5–10° to face the opener. That tiny pitch feels luxe. You’ll see fewer re-shoots for product pages because the orientation is “always right.”

Clamshell Boxes

For sets and accessories, clamshells keep components in one plane. Add die cut wells with finger-arches so parts lift easily. No digging, no mess.

Drawer Style Boxes vs. Magnetic Closure Boxes

- Drawer style: continuous reveal, tactile pull, compact depth.

- Magnetic closure: audible “click,” crisp edges, easy reseal. Both accept die cut cradles and windows. Choose based on brand tone and retail planogram.

E-Commerce Packaging

Ship-ready mailers plus internal die cut guards reduce breakage and returns. Print a clear returns path under the lid. Keep double duties: same box demos on arrival and protects in transit. No need for extra outer, unless your carrier requires it.

Material & Finish Stack

Start with the structure, then layer finishes: emboss/deboss, foil, spot UV, soft-touch or matte. Don’t over-print. White space sells quiet luxury. If sustainability is a must, pick mono-material flows and removable film windows.

Quick Bill of Materials (BOM) Tips

- Board caliper matched to weight; test drop from 80–100 cm.

- Insert kerf tolerances ±0.5–1.0 mm around the critical dimensions.

- Window film anti-fog for food; anti-scratch for retail samples.

- Pantone control chips taped to proofs—avoid screen-to-press drift.

Why ChinaCustomBoxes

We customize rigid paper boxes, folding cartons, tube boxes, and paper shopping bags at scale. We support bulk wholesale, OEM/ODM, and private label teams—from global perfume procurement to startup founders. We proof fast, cut clean, and ship on schedule. You get one partner for shapes, industries, and print.