Printing on cardboard boxes isn’t just about putting your logo on a brown surface. It has to do with transforming every box right into a brand name writer. Whether you’re tailoring for fragrance brands or Mailer Boxes for ecommerce delivery, print quality makes or damages first impressions.

Understanding Cardboard Surface and Printing Difficulties

Cardboard is porous, distinctive, and not constantly smooth. That indicates ink does not act the like on covered paper. Excessive ink, and it hemorrhages; insufficient, and shades look discolored. In packaging terms, we call this ink absorption balance . For example, kraft mailer boxes take in more ink than with laminated surfaces.

| Challenge | Summary | Impact |

|---|---|---|

| Permeable surface | Ink passes through deep, shedding vibrancy | Discolored shades |

| Irregular appearance | Ink spreads erratically | Blurred logo design edges |

| Low shade contrast | Brownish base dulls brilliant tones | Hard-to-read print |

If you want your logo design to pop, pre-coating or lamination can aid secure the surface prior to printing.

Choosing the Right Printing Approach

Each technique fits various spending plans, amounts, and layouts. At China Custom-made Boxes , we make use of numerous printing processes to match customer objectives.

Flexographic Printing

Utilized for bulk orders– like E-Commerce Packaging — flexo printing functions fast and costs less per box. It utilizes rubber plates and quick-drying ink, terrific for easy logo designs and delivery marks.

Offset (Lithographic) Printing

If your brand name concentrates on high-end, like fragrance or precious jewelry, balanced out printing gives costs photo quality. Think about those perfect you see in boutique stores– crisp sides, abundant shades, and high consistency.

Digital Printing

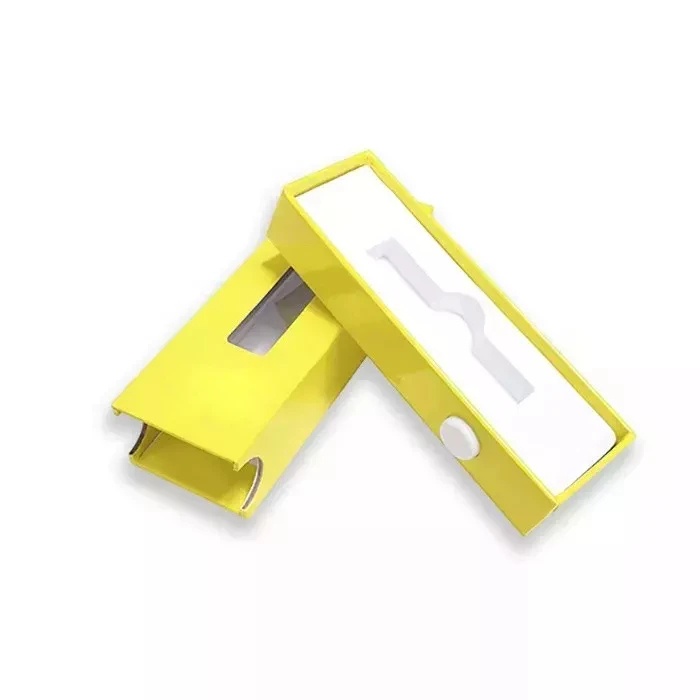

For startups or seasonal projects, electronic printing is a lifesaver. No printing plates, quickly setup, and simple artwork modifications. Perfect for limited-edition Collapsible Gift Boxes or small-batch promotions.

Display Printing

A classic for bold graphics. It applies thicker ink layers and functions perfectly on Unusual Shaped Boxes or textured products. Not the fastest, but irresistible when you need strong, tactile color.

Readying Your Artwork and Box for Printing

Before striking “print,” it’s crucial to prepare correctly.

- Pick the ideal cardboard kind — single wall for retail, double wall surface for delivery.

- Settle dieline — your box’s template with layer and cut lines.

- Include hemorrhage — extend layout past sides to avoid white voids.

- Examination small batch — constantly ask for a pre-production example.

At LOVINHUG , our style group checks every dieline to ensure your shades stay sharp, also across folds and edges. Nothing worse than a cut-off logo design on the front panel!

Printing Quality and Longevity Specifications

Printing on cardboard isn’t simply aesthetic– it should survive transport, humidity, and shelf display. Right here’s what matters most:

| Top quality Element | Summary | Why It Issues |

|---|---|---|

| Color precision | Shade matches brand name palette | Makes certain uniformity |

| Ink bond | Ink resists scratches | Shields style |

| Barcode readability | Codes publish plainly | Easy scanning in logistics |

| Complete security | UV finishing, lamination | Includes gloss or matte sturdiness |

As an example, in Candle Packaging Boxes , UV-coated logos stand up to wax smudge and wetness. At the same time, typically obtain matte lamination to include that high-end touch.

Harmonizing Expense, Quantity, and Sustainability

Every organization asks the very same thing: exactly how do we maintain expenses down without cutting quality? The answer lies in clever pairing of materials and print methods.

- Flexo + kraft board = best for high-volume shipping

- Countered + covered paper = finest for retail display

- Digital + brief runs = suitable for trial or gift collection

Sustainability is no longer optional. Making use of soy-based inks and recyclable products not only assists the planet yet likewise attracts eco-minded consumers. Our Paper Shopping Bags , for example, use 100% recycled kraft with water-based ink– solid, lasting, and elegant.

Industry Applications and Real Scenarios

Allow’s consider exactly how printing adjustments across industries:

- Cosmetics: Vivid countered printing on Cosmetics Product Packaging Boxes develops trust fund and rack allure.

- Ecommerce: Flexo-printed with bold branding increase unboxing experience.

- Food & Red Wine: Waterproof finish on Red Wine & State Of Minds Product Packaging Boxes protects color throughout cold-chain delivery.

- Electronic devices: Specific barcodes and tidy digital print on make certain traceability.

Each industry has distinct criteria– longevity for logistics, visual beauty for retail, or compliance for child-resistant packaging. That’s why our designers adapt every print layer to satisfy those exact needs.

Specialist Tips for Better Results

- Stay clear of a lot of colors — basic layouts print cleaner.

- Use bold fonts — thin lines blur on corrugated surface areas.

- Add coverings smartly — gloss for sparkle, matte for elegance.

- Testimonial models under actual light — manufacturing facility lights can misdirect tone understanding.

- Think recyclability — water-based inks sway solvent ones.

And yes, always examination. Even if you’ve printed 10,000 boxes before, every batch of cardboard behaves differently.

Verdict

Printing on cardboard boxes is both science and art. From flexo on mailers to countered on fragrance boxes , each option impacts price, quality, and brand effect. At China Custom-made Boxes Manufacturing Facility , we transform simple cardboard right into high-value packaging that offers. Whether you require Uncommon Shaped Boxes or common folding cartons, our team at Chinacustomboxes ensures every shade and cut talks your brand name’s language.