If you sell earbuds, chargers, cables, or a smart watch band, you need packaging that protects, looks premium, and doesn’t slow your line. Lid and base rigid boxes (aka top and bottom boxes) tick those boxes. They’re sturdy, brandable, and easy to scale. Below I’ll keep it real, show practical scenes, and link a few pages on China Custom Boxes Factory so you can jump straight to sourcing.

Quick fit: This article speaks to brand owners, procurement teams, packaging traders, and OEM/ODM buyers who need custom, bulk, wholesale-ready solutions.

Lid and Base Boxes for Phone Accessories (Top and Bottom Packaging Boxes)

A lid lifts off a solid base. That simple two-piece structure gives you compression strength, cleaner edges, and a “slow reveal” unboxing people remember. You can drop in an EVA, IXPE, or pulp tray to lock parts so they don’t rattle. You can go with full-cover lids for a tight, premium feel or half-cover for faster pick-and-pack.

Internal link: Lid and Base Boxes

Why “Rigid Boxes Protective” works in real shipping

- Thick greyboard + wrapped art paper resists dent and squeeze.

- Trays stop micro-movement. That reduces drop shock on corners.

- Square geometry stacks well, so outer cartons cube out clean.

- In stores, the box doubles as a display asset. No floppy walls.

Key Arguments & Proof Points (Quick Table)

| Claim (What we promise) | What it means for you | How to test in your ops | Notes from the floor |

|---|---|---|---|

| Higher crush resistance | Better survival in courier hubs | Simple stack test + free drop baseline | Add corner blocks for glassy parts |

| Fewer returns from damage | Less DOA accessories | Track RMA reason codes month-over-month | Tray fit is 80% of the battle |

| Faster kitting & QC | Parts slot in one way only | Time one packer over 50 kits | Color code cavities if SKUs share a shell |

| Shelf-ready branding | Premium unboxing without inserts | Lay out front face with minimal copy | Foil logo + soft-touch film feels high-end |

| Flexible SKUs, one family | Same shell, swap trays | Keep board caliper constant | Cuts tooling churn, helps MOQ control |

| Better sustainability path | Mono-material options | Try paper-pulp trays, water-based ink | Skip magnets if you can—use friction fit |

Top and Bottom Packaging Boxes Vendor for Phone Accessories

You want a vendor who speaks die-line, board caliper, and assembly rate per minute. You also want real OEM discipline: clean files, pilot runs, pre-production samples, and a repeatable QC gate.

Internal link: Top and Bottom Packaging Boxes Vendor for Phone Accessories

What to brief:

- Protection tier: courier only, or courier + retail?

- Tray choice: EVA/IXPE for shock; molded pulp for eco; folded card for light pieces.

- Lid type: full cover for slow-fall open; half cover for fast open.

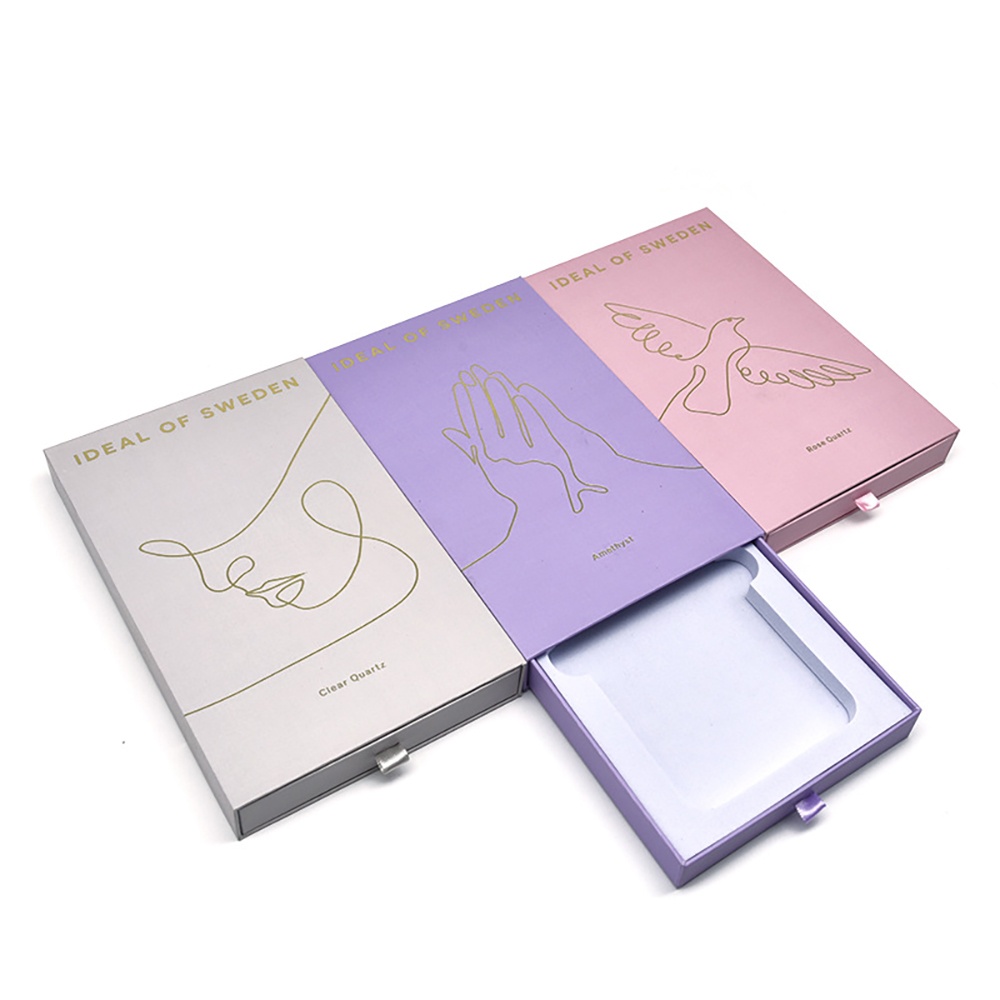

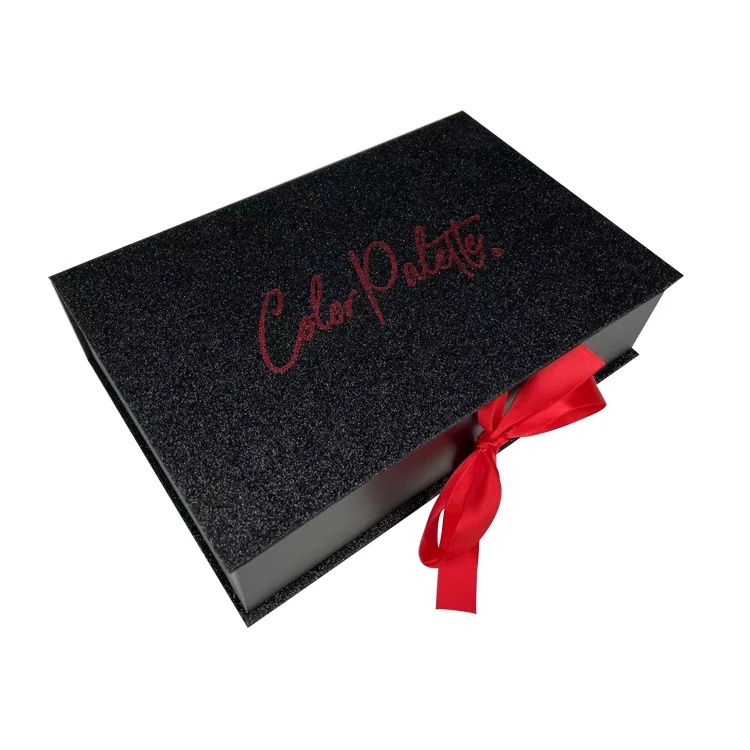

- Finish: matte film, soft-touch, emboss/deboss, spot UV, foil.

- Print info: model list, UPC/EAN, compatibility icons. Keep the front clean.

Elegant Lid and Base Gift Box Smart Watch Packaging Solution

Smart watch bands and pods need scratch-safe cavities and a snug tolerance. A common stack: 2.0–2.5 mm board + wrapped art paper + soft-touch finish + foam or pulp tray + quick-start card tucked under the tray.

Internal link: Elegant Lid and Base Gift Box Smart Watch Packaging Solution

Real scene:

- DTC drop: box goes mailer → client’s door. Add a thin sleeve to hide scuffs.

- Retail peg: add a side label with variant code, keep the face logo-only.

- Influencer kit: include a foam-kiss cut for extra straps; make the lid “slow fall” for the camera.

Custom Tempered Glass Screen Protector Packaging Box Factory

Glass is unforgiving. Use a stiff base, plus EVA with a raised lip to guard the edges. Add a flat kit space for wipes and dust stickers. For volume lines, laser-cut trays speed assembly and reduce scrap.

Internal link: Custom Tempered Glass Screen Protector Packaging Box Factory

Pro tips:

- Mark the tray with tiny “A/B” emboss so packers don’t flip it wrong.

- Use peel-tab paper to stage small kit pieces, less chase on the line.

- If magnets aren’t needed, don’t add them. Friction fit is enough and greener.

Lid And Base Box Mobile Cell Phone Packaging Box Factory

For full phone kits or premium bundles, full-cover lids create that slow-air drop effect. It signals quality and keeps parts seated. Map layers: phone or main unit on top, cable and brick under, docs in a sleeve.

Internal link: Lid And Base Box Mobile Cell Phone Packaging Box Factory

Layering that works:

- Tier 1: hero product.

- Tier 2: cable, charger, tips, SIM tool.

- Tier 3: literature, warranty, QR code to video guide.

Materials, Trays, and Finishes (What to choose when)

Board & wrap

- Keep board caliper steady across the line to lock in compression behavior.

- Choose coated art paper for crisp color; pick pearl, glitter, or holographic wraps only when it serves your brand story.

Trays

- EVA/IXPE: strongest hold, clean edges, easy color match.

- Molded pulp: mono-material path, still neat with right tooling.

- Folded card: light duty, cheapest feel but fast to change.

Finishes

- Soft-touch: premium handfeel; watch scuff resistance.

- Foil: instant pop; keep it small and sharp.

- Spot UV: gloss against matte for contrast.

- Emboss/deboss: tactile logo without loud ink.

Field Scenarios (from warehouse to customer hands)

- 3PL chaos: cartons stack and slide. Rigid bases keep corners alive. Your RMA chart goes calmer.

- Pop-up retail: boxes double as risers; face-out logo sells itself.

- Crowded SKU tree: same shell, swap trays and labels; planning smiles.

- Influencer seeding: the “lift and float” open feels luxe on video.

- Returns loop: boxes survive the ride back; refurb line gets cleaner units.

Quick Buyer’s Checklist (copy/paste to your RFQ)

- Structure: two-piece lid & base, specify full-cover or half-cover.

- Protection: define drop/stack baseline; call out fragile edges.

- Tray: EVA / IXPE / molded pulp / folded card; include CAD with tolerances.

- Finish: matte or soft-touch + optional foil/UV/emboss.

- Print: high-legibility fonts, minimal face text, side sticker for variant.

- QC: incoming board caliper check, tray fit test, lid “slow fall” timing (rough, not rocket sciense).

- Pack-out: one direction only, add micro-icons for assembly hints.

Mini Case: LOVINHUG earbuds launch

LOVINHUG shifted from thin folding cartons to lid & base rigid with a custom IXPE tray. Kitting time dropped because parts only fit one way. Retailers told them the box “sits straight” on shelf. Returns from scuff damage dipped. The unbox looked classy on short videos, which kinda pushed repeat buys. Not magic, just better fit.

FAQ (kept short)

Will a rigid box be too heavy? It’s heavier than a folding carton, yes. But you gain stiffness and a premium feel. If weight is tight, go half-cover lid and pulp tray.

Do I need magnets? Not always. Friction fit works. Magnets add cost and recycling complexity.

Is pulp tray neat enough? With clean tooling and bleached pulp, yes. Print the inner lid to keep the look tight.

Who we are (and why it matters)

China Custom Boxes Factory is a leading manufacturer in China. We customize Magnetic Closure Boxes, Lid and Base Boxes, Drawer Style Boxes, Collapsible Gift Boxes, Clamshell Boxes, Unusual Shaped Boxes, Paper Tube Boxes, Mailer Boxes, Folding Cartons, Child Resistant Packaging, Paper Shopping Bags. We serve large fragrance buyers, mid-size brands, startups, packaging traders, private-label teams, and OEM/ODM partners. You want bulk, wholesale, custom print, and steady lead times—we do that.