You look at a bright mockup on your laptop and then the sample box lands on your desk—colors shift, reds mute, deep blues look kinda dull. That’s normal. Screens glow; paper reflects. CMYK is how ink on paper makes color look right and stay stable on press.

CMYK Color Model (Subtractive Color on Paper)

CMYK stands for Cyan, Magenta, Yellow, and Key/Black. It’s a subtractive color model. In plain words: inks absorb light. White paper reflects light back to your eyes; each ink layer removes part of the spectrum. Stack inks and you get darker tones. That’s why packaging print shops (like ChinaCustomBoxes) run CMYK as the baseline for cartons, mailers, tubes, and bags.

Why screens fool you (RGB vs CMYK color gamut)

RGB on a screen is additive—tiny lamps mixing light. RGB can show ultra-vivid neons that CMYK can’t fully reproduce. When you convert artwork to CMYK, some high-saturation colors “fall outside” the CMYK gamut. So proofs matter. Soft-proof your file in CMYK, then request a hard proof before mass run.

Why the K (Black Ink) Matters for Packaging Print

Could we build black by stacking C+M+Y? Technically yes, practically no. A “three-ink black” dries slow, looks muddy, and risks mis-registration. A dedicated K channel solves it:

- Sharper small text and barcodes (less sensitive to registration drift).

- Cleaner neutrals and rich shadows.

- Reduced total ink coverage in dark areas, which helps drying and rub resistance.

GCR/UCR (Gray Component Replacement & Under Color Removal)

Prepress uses GCR/UCR to swap the gray part of CMY with K. That stabilizes neutral grays, lowers ink load, and keeps print consistent across lots. It’s a boring acronym with big impact: smoother gradients, calmer darks, fewer drying headaches.

Halftone Screen Angles and LPI in Offset/Flexo

Presses don’t lay down “continuous” tones; they print halftone dots. Changing screen angles for C, M, Y, and K keeps patterns from clashing and avoids moiré. LPI (lines per inch) sets dot density: higher LPI = finer detail (requires better stock and tight press control). For retail packaging, we balance LPI and coating so text stays pin-sharp and brand colors hold repeat to repeat.

Total Ink Coverage (TAC) and Drying Control

Paper and coatings can handle only so much ink. TAC (Total Area Coverage) caps the combined C+M+Y+K in any spot. Keep TAC in spec and you reduce set-off, smearing, and drying issues. Non-coated stocks demand lower TAC than glossy art paper; corrugated liners prefer conservative builds. If you hear our prepress team say “we’ll reduce TAC and push more K,” that’s us protecting your schedule and shelf-ready finish.

ICC Color Profiles and Proofing (GRACoL/FOGRA)

Color isn’t a vibe; it’s a profile. ICC profiles describe how a specific press/ink/paper combo reproduces color. We assign the right profile (e.g., GRACoL/FOGRA families) to your artwork, convert from RGB if needed, and proof against that condition. This way your red on the Magnetic Closure Boxes matches the red on your Lid and Base Boxes—same brand, different formats, consistent tone.

CMYK vs RGB: Practical Packaging Scenarios

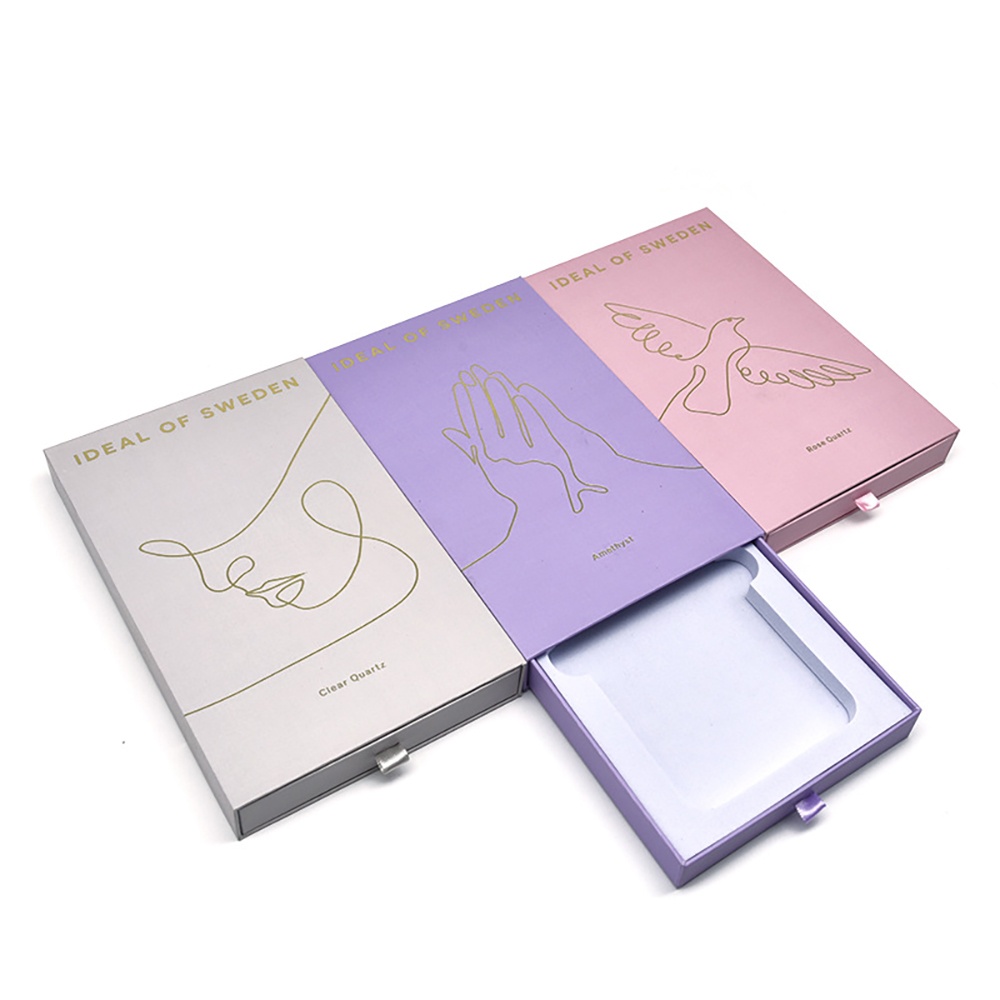

- Perfume sleeves & rigid sets: Jewel-tone purples often need a tuned CMYK build and tight GCR to avoid color drift across batches.

- Food cartons: Warm reds and oranges convert fine, but ultra neon accents may require spot inks.

- CBD and pharma: Readability first—K-only micro text for dosage, CMYK pictures for lifestyle shots, compliant with Child Resistant Packaging requirements.

- E-commerce mailers: Kraft substrates mute colors; we raise K and manage TAC to keep logos punchy on brown stock.

- Paper tubes: Cylindrical forms show banding if gradients aren’t built with smooth CMYK ramps. We test screens on Paper Tube Boxes early.

Table: Core Reasons CMYK Wins in Print

| Topic | Key Takeaway | What it means for your box |

|---|---|---|

| Subtractive color (CMYK) | Ink absorbs light on paper | What you see depends on paper + ink, not backlight |

| Dedicated K channel | Sharper type, stable neutrals | Crisp micro text, clean barcodes, deeper blacks |

| GCR/UCR | Replace CMY gray with K | Lower ink load, smoother grays, fewer drying issues |

| Halftone screens & angles | Avoid moiré, keep tones smooth | Fine images without weird patterns |

| LPI selection | Match detail to substrate | Right balance of detail vs cost and stability |

| TAC limit | Cap total ink in dark zones | Faster dry, less set-off, better throughput |

| ICC color profiles | Predictable, repeatable color | Consistent brand tones across SKUs & reprints |

| CMYK < RGB gamut | Some neons/metallics out of range | Consider spot colors or coatings when needed |

Real Use Cases with ChinaCustomBoxes

- Cosmetics & fragrance: Many purples/teals sit on the edge of CMYK gamut. We soft-proof, then either finesse the CMYK build or propose a spot ink for that hero hue. Check our Cosmetic Packaging Boxes for rigid sets and sleeves.

- Gifting and retail: For seasonal runs, Collapsible Gift Boxes ship flat, print CMYK efficiently, and pop up on site—less warehouse pain, same luxury look.

- Shapes & structures: Odd dielines can stretch gradients. See Unusual Shaped Boxes and Boxes by Shapes; we pre-flight art to avoid tone breaks on tricky folds.

- D2C brands: Mailers and Folding Cartons share ink builds so your unboxing feels coherent, even with mixed substrates.

Prepress Checklist (simple but powerful)

- Set document to CMYK from the start when print is the goal.

- Assign the correct ICC profile for the intended stock/press.

- Use GCR/UCR to stabilize grays; avoid fake “rich black” everywhere.

- Respect TAC; push density with coatings or spot colors if needed.

- Proof: soft-proof + contract proof before bulk run.

- Keep tiny text in 100% K for best legibility.

- Watch gradients on curves, sleeves, tubes (yes, tube art can band if the build is wrong).

- RGB assets? Convert with intent; don’t just drop them in and hope. Color are tricky—do the conversion on purpose.

Industries We Serve (keywords you actually search)

Fragrance, beauty, candle, jewelry, gourmet, apparel, consumer electronics, wine & spirits, cannabis/CBD, e-commerce. Explore Boxes By Industries to see tuned structures—rigid sets, drawers, clamshells, mailers, tubes, and more. We support OEM/ODM, bulk, and brand-new startups needing fast-learning support. If you need child-resistant, we route you to compliant builds and labels without killing the look.

CMYK, But Elevated: When to Add Beyond Four Colors

CMYK does the heavy lifting. If your brand color falls outside CMYK (certain neons, metallics), we can add a spot color, a soft-touch or gloss varnish, foil, or emboss to achieve pop without breaking TAC. That’s often smarter than forcing saturated CMYK and ending with muddy shadows. Don’t worry, we’ll flag it in prepress so you won’t get suprises later.

Why ChinaCustomBoxes

We’re a manufacturing partner, not just a printer. We tune Magnetic Closure Boxes, Lid and Base, Drawer Style, Paper Tubes, Mailers, Folding Cartons, Paper Shopping Bags to the reality of CMYK on your chosen stock. We manage color with profiles, watch TAC, pick screens, and deliver repeatable results—from pilot to scale. You don’t wanna fight color every reorder.

Data Snapshot: CMYK Print Controls at a Glance

| Control | Typical Decision | Benefit |

|---|---|---|

| ICC profile | Match press + stock (GRACoL/FOGRA family) | Predictable brand color |

| TAC | Kept within substrate spec | Faster dry, fewer defects |

| GCR/UCR level | Moderate to strong GCR | Stable neutrals, less ink |

| LPI | Tuned to paper & artwork | Smooth images, crisp text |

| Black build | Use K-only for micro text; balanced rich black for solids | Readability + deep fills |

Quick Definitions (for fast onboarding)

- CMYK: Ink model for print; subtractive color on paper.

- GCR/UCR: Strategies to replace CMY gray with K and reduce ink.

- TAC: Maximum combined ink allowed in one area.

- ICC Profile: File that defines how a device renders color.

- LPI/Screen Angles: Dot density and direction that build tones.