Introduction

Against the backdrop of global supply chain reconstruction, China has become the core hub for the global manufacturing of customized packaging boxes. According to Statista data, the market size of China’s packaging industry is expected to exceed 2.5 trillion yuan in 2025, accounting for more than 30% of the global market share. Companies choose to cooperate with Chinese suppliers to customize packaging boxes, not only because of their cost advantages, but also because of their comprehensive competitiveness in technology, design, supply chain and innovation. This article analyzes the global appeal of China’s packaging box manufacturing from eight dimensions, and demonstrates its irreplaceability with industry cases and data.

1. Cost-effectiveness: large-scale production and flexible cost control

The large-scale production of China’s manufacturing industry has significantly reduced unit costs. For example, a packaging factory in Dongguan has reduced labor costs to 1/5 of the European and American markets through automated production lines, and adopted a localized raw material procurement strategy (such as bamboo pulp paper replacing imported specialty paper) to reduce packaging box costs by 30%. Alibaba platform data shows that the minimum order quantity for customized packaging boxes in China can be as low as 500 pieces, while the European and American markets usually require more than 5,000 pieces. This flexibility saves inventory pressure and capital occupation for small and medium-sized enterprises.

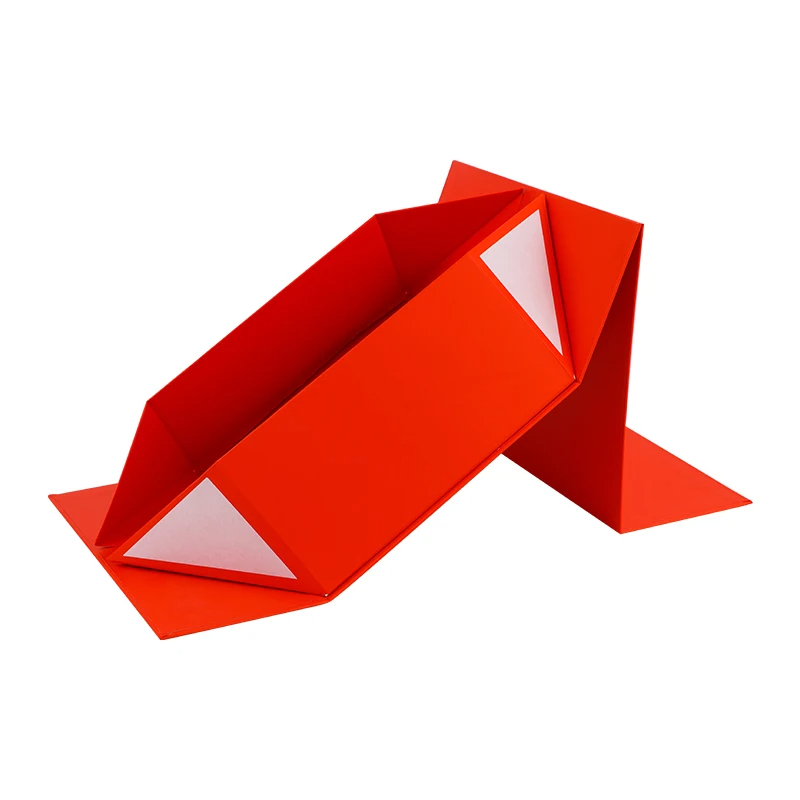

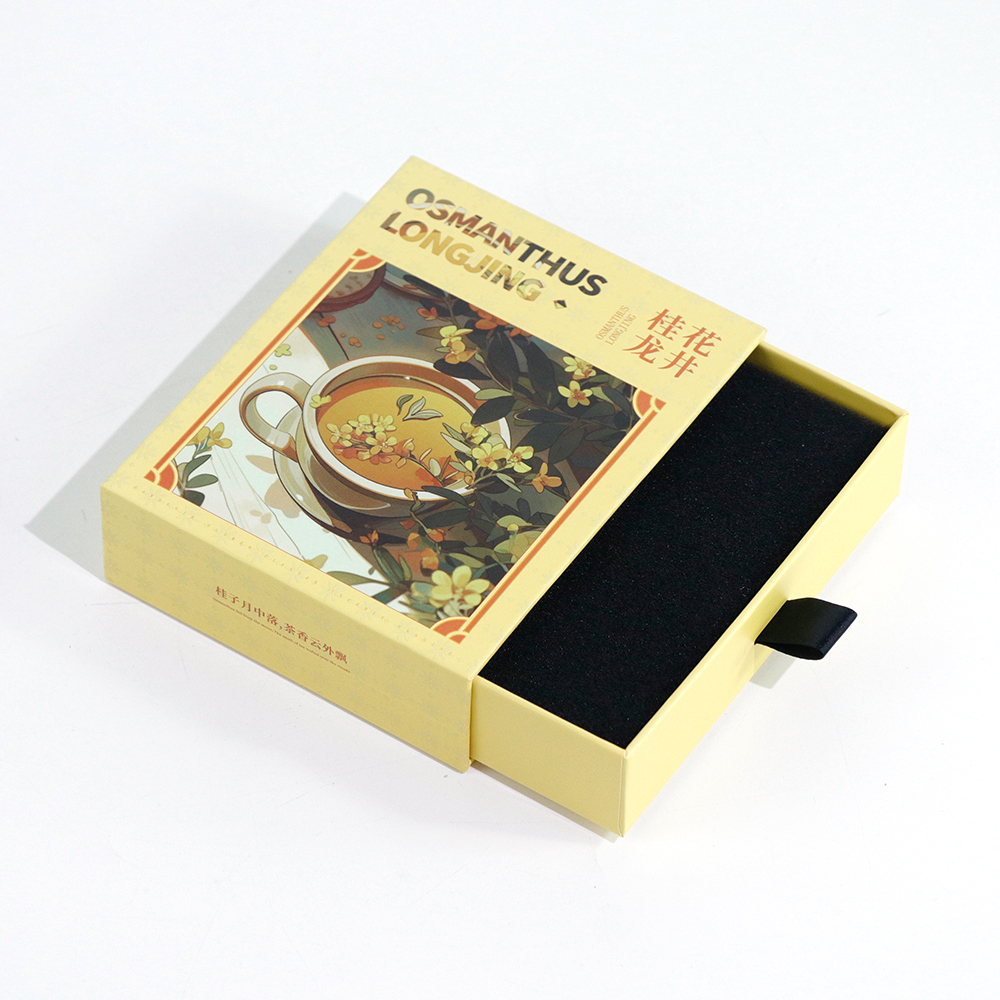

2. Design innovation capabilities: cultural integration and customized solutions

Chinese suppliers combine traditional culture with modern design to form a unique “Chinese style” competitiveness. For example, Jingdezhen ceramic companies use 3D relief technology to incorporate blue and white porcelain patterns into tea packaging boxes, and the product premium increases by 40%. Head companies equipped with professional design teams to support the full process development from concept sketches to 3D modeling. The limited edition gift box of an international cosmetics brand only takes 21 days from design to mass production in China, which is 50% shorter than the cycle of European suppliers.

3. Material science breakthrough: dual upgrade of environmental protection and functionality

Chinese packaging companies are the first to realize the industrial application of degradable materials. The corn starch-based packaging box developed by Shandong Chenming Group can be completely degraded within 45 days and has passed the EU EN13432 certification. The cost is only 15% higher than traditional plastic packaging. Wuhan Zeya Printing launched the “intelligent temperature-controlled packaging box” with a built-in NFC chip, which can monitor the cold chain data of medicines in real time, and the number of technical patents ranks among the top three in the world.

4. Efficient supply chain and delivery capabilities

Relying on the industrial cluster advantages of the “world factory”, the Pearl River Delta packaging industry belt can achieve 72-hour ultra-fast proofing. A Shenzhen electronic brand has compressed the new product packaging delivery cycle from 6 weeks to 10 days through the JIT (just-in-time) production model of Dongguan suppliers, supporting global simultaneous listing. Cainiao Logistics data shows that the shipping time of packaging materials from China to major ports in Europe and the United States is stable at 18-22 days, which is 30% faster than the Southeast Asian supply chain.

5. Quality control system: digitalization enables manufacturing precision

Heading companies introduce ISO15378 pharmaceutical packaging standards and AI quality inspection systems. Member units of the Chao’an Packaging Association use machine vision inspection to control the color difference tolerance of printing at ΔE≤1.5, which is better than the internationally accepted ΔE≤3 standard. A red wine packaging factory, uses blockchain traceability technology to achieve full-process traceability from wood procurement to finished product delivery, and the customer complaint rate has dropped to 0.03%.

6. Policy support and industrial cluster effect

The Chinese government has included the packaging industry in the key areas of “Made in China 2025”. Dongguan, Wenzhou and other places have built national-level packaging innovation industrial parks, providing a 15% VAT discount. Take Anbu Town as an example. This “China’s No. 1 Printing and Packaging Town” has gathered more than 2,000 upstream and downstream companies, forming a complete ecological chain from design, mold development to environmentally friendly ink supply.

7. Global Service Capabilities: Multilingual and Compliance Guarantee

Listed companies such as Shenzhen Yutong Technology have established overseas design centers to support packaging copywriting in 12 languages including English, French, and Arabic. A Middle Eastern luxury brand obtained food-grade ink certification that complies with Islamic law through a Shanghai supplier and successfully opened up the market of the six Gulf countries. According to Chinese customs data, 32% of export packaging boxes in 2024 will be directly marked with environmental certification logos of the destination country, such as FSC and EPC.

8. Innovative R&D investment: smart packaging and cross-border integration

The annual R&D investment of Chinese packaging companies accounts for 4.2%, higher than the global average of 2.8%. The AR packaging box developed by a Hangzhou company can present 3D product demonstrations through mobile phone scanning, which increases customer conversion rate by 27%. A tea brand in Yunnan combines NFC chips with Pu’er tea cake packaging. Consumers can scan the code to view the tea tree growth video. This technology won the 2024 World Packaging Organization (WPO) Innovation Gold Award.

Conclusion: Global Value Reconstruction of China’s Packaging Manufacturing Industry

From cost depression to innovation heights, China’s packaging box manufacturing industry has completed the transformation from “world factory” to “global intelligent manufacturing center”. According to McKinsey’s forecast, by 2030, China’s share of the global high-end customized packaging market will jump from the current 18% to 35%. For companies pursuing brand differentiation, cost optimization and sustainable development, cooperation with Chinese suppliers is not only a business choice, but also a strategic decision to participate in the upgrading of the global value chain.