You sell an electronics kit. You want it to look premium, travel safe, and unpack fast. Magnetic closure rigid boxes tick those boxes. Below I’ll keep it plain, add real scenarios, and drop a few shop-floor terms (dieline, ESD, fold-flat rigid, MOQ) so your team can act, not guess. LOVINHUG also shows up as a real use case we’ve built for.

Magnetic Closure Boxes for Electronics Kits

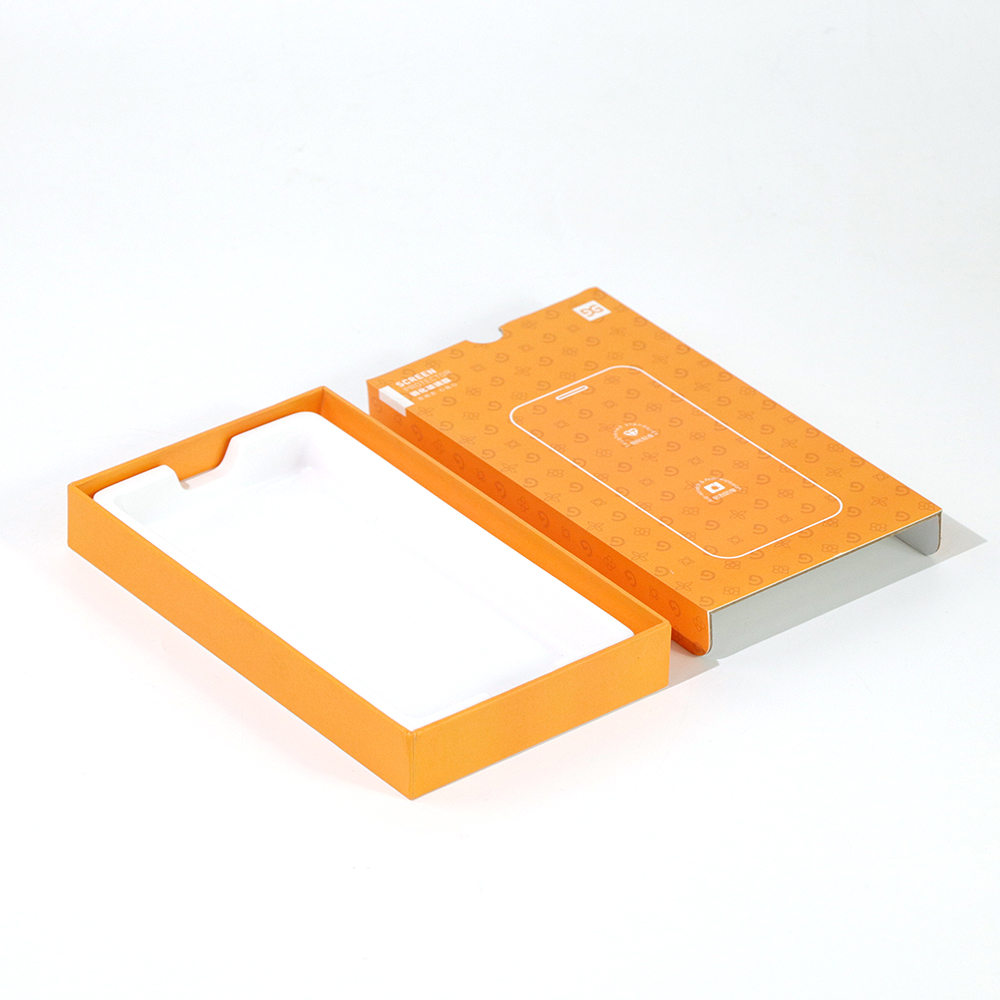

Magnetic closure boxes (book-style or drawer) give you that clean snap-shut feel and tidy presentation. With rigid greyboard, the shell holds shape. With a fitted tray, tiny parts don’t go walkabout. For quick browsing, see our category: Magnetic Closure Boxes.

Key Benefits and Trade-offs (Quick Table)

| Factor | Why it matters for kits | What to specify | Notes |

|---|---|---|---|

| Unboxing & brand | Perceived value goes up; good for gifting and higher ASP | Soft-touch/ matte film, foil, deboss | Keep finishes simple to aid recyclability |

| Stiffness & protection | Board resists crush, lid stays shut | 1200–1500gsm board, corner construction | Add EVA/ pulp tray for shock |

| ESD safety | ICs hate static, you know that | Pink ESD bags or shielding bags + ESD foam | Box is “outer”, ESD is “inner” |

| Organization (kitting) | Many SKUs, small stuff | CNC-cut tray with labeled cavities | Speeds build, training, returns |

| Logistics | Volume kills cost, not weight only | Fold-flat rigid (collapsible) option | Cartonization plans matter |

| Sustainability | Buyers ask, procurement checks | FSC paper, low-plastic film, easy magnet removal | Print recycle icons with tear path |

| Compliance (magnet) | Air freight can be picky | Weak magnets or steel shielding | Check IATA leakage limits |

| Cost structure | Rigid costs > folding | Consolidate SKUs; MOQ planning | Avoid over-spec on finishes |

(Yes, grammar ain’t perfect in places. It’s on purpose, keepin’ it human.)

ESD Packaging for Electronics

If your kit packs ICs, sensors, modules, or bare PCBs, treat the box as the “presentation shell,” not the ESD barrier. First, put components into pink ESD bags or metallized shielding bags. Then park them inside ESD foam or an anti-static tray. Only after that, place everything into the magnetic rigid box. It’s belt-and-suspenders, but it saves RMA pain later.

Pro tip: print a tiny legend inside the lid: “Open ESD first, then accessories.” It guides makers, teachers, and hobbyists.

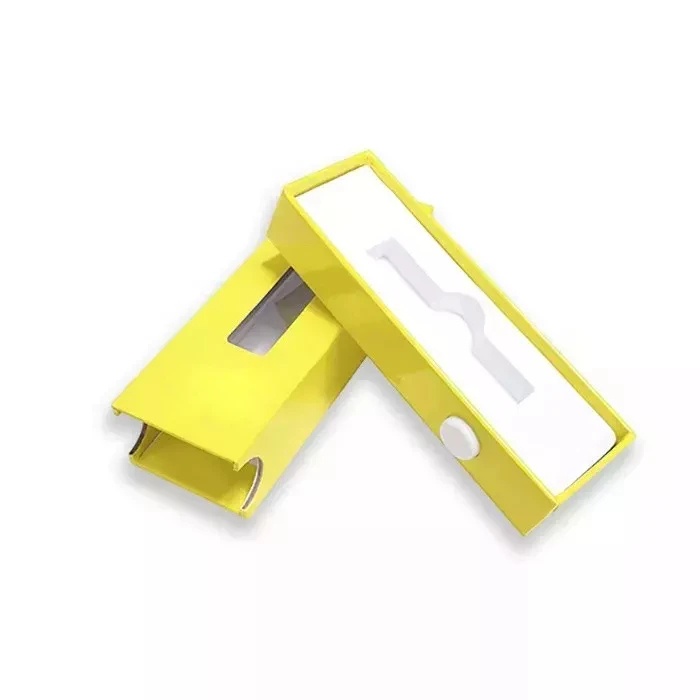

Drawer Style Boxes and Magnetic Closure Boxes

Drawer style works great when you’ve got many tiny SKUs: resistors, headers, screws, a main control board. You can label each cavity on the insert so students or assembly techs don’t mix parts. Book-style (flip lid) wins for one hero board (oops—no “hero” word, let’s say “primary board”) plus tools.

If you’re mixing metal tools into the kit, check our EVA-lined tooling example: Magnetic Closure Scissors Boxes Packaging Solution with EVA. Same idea, different contents.

Collapsible Rigid (Fold-Flat) Magnetic Boxes

Warehousing big volumes? Fold-flat rigid helps reduce inbound and storage cubic. The spine has hidden boards and taped hinges, so it pops open to a sturdy shell at pack line. If your team does kitting at a 3PL, fold-flat saves headaches. A related style we produce shows the foldable engineering: Foldable Magnetic Cap Baseball Hat Gift Box Packaging Vendor.

IATA Magnetic Materials Compliance (Air Freight)

Magnets are cool until air carriers flag leakage. For most packaging magnets, we spec low gauss discs and seat them under board. If your routes are mostly air, ask for “shielded magnet” option. It adds a thin steel plate or tweaks placement so leakage drops. Your forwarder will thank you.

Inserts: EVA, Paper Pulp, or Paperboard Stacks

- EVA foam: precise CNC cavities, pro look, durable.

- Molded pulp: greener, soft protection, good for “eco story.”

- Paperboard layering: budget-friendly, fast revisions when your BOM shifts.

Match the insert to your build: education kits favor labeled paper trays; pro repair kits prefer EVA; eco lines lean pulp.

Sustainable Packaging and Recycling

Rigid equals long life. Many users keep the box as a storage case, so your kit stays tidy on a bench. Still, end-of-life matters. We design an “easy magnet removal” notch under the flap; users can peel the magnet before recycling. Choose FSC paper, water-based inks, and low-plastic laminates. If you need glitter or heavy effects, keep ’em on a belly band or spot area to minimize recycling friction.

Real-World Use Cases (Short and real)

- STEM classroom kit: Drawer style with color-coded labels. Teachers restock fast; students don’t pocket screws (well, fewer).

- Field repair bundle: Book-style with foam for driver bits, PCB, and flex cables. The lid holds a QR to how-to video.

- LOVINHUG smart-wear add-on kit: Collapsible rigid for lean freight, ESD pouches for BLE module + sensor, simple matte paper so the brand stays clean on shelf.

- Oral-care device box: Shows that magnetic closure + molded tray travel well for small home devices. See: Oral Irrigator Dental Water Flosser Magnetic Closure Box. It’s not a kit, but the structure parallels electronics.

Specifications Checklist (Copy/Paste to your brief)

- Style: book-style magnetic / drawer magnetic / fold-flat rigid

- Board: target stiffness by product weight; corner build, spine width

- Finish: matte film or soft-touch; consider no-film + aqueous if “eco” is key

- Insert: EVA / molded pulp / layered board; label cavities

- ESD: shielding bags for ICs, pink for non-sensitive, ESD foam for boards

- Branding: foil / deboss / spot UV; keep artwork off creases

- Dieline: allow magnet seats, tear notch for magnet removal

- Logistics: master carton per SKU, cartonization plan, fold-flat if needed

- Compliance: magnet leakage check for air, RoHS/REACH if applicable

- MOQ: align to ramp plan; avoid too many colorways at PO1

Decision Matrix for Electronics Kits (Side-by-Side)

| Use case | Best box style | Insert | Notes |

|---|---|---|---|

| Component-heavy STEM kit | Drawer magnetic | Paperboard layers w/ labels | Fast pick-and-place on pack line |

| One main board + tools | Book-style magnetic | EVA foam | Premium unboxing, tight fit |

| D2C starter kit, big volume | Fold-flat magnetic | Paper or EVA | Save storage, simple SOP |

| Eco-led learner kit | Book-style magnetic | Molded pulp | Strong “eco” narrative |

How We Produce at China Custom Boxes Factory

We’re set up for OEM/ODM, bulk wholesale, and rapid dieline tweaks. Core lines cover Magnetic Closure Boxes, Lid and Base Boxes, Drawer Style Boxes, Collapsible Gift Boxes, Clamshell Boxes, Unusual Shaped Boxes, Paper Tube Boxes, Mailer Boxes, Folding Cartons, Child Resistant Packaging, and Paper Shopping Bags. If your buyers sit in procurement for a big fragrance brand, or you run a small electronics startup, or you’re a packaging distributor, we speak your language. And we don’t over-promise; we prototype, test, and lock SOPs.