China Custom Boxes Factory · Magnetic Closure Boxes · OEM/ODM

You want premium look, greener materials, and repeatable OEM quality. You also want simple spec, real factory talk, and links you can click. Let’s keep it practical and a bit chatty. We’ll cover recycled boards, inks, closures, compliance, logistics, and how to brief your supplier (that’s us). I’ll also drop a few real product links from your site so your team can cross-check details fast.

Magnetic Closure Boxes • Custom Hemp Oil Magnetic Closure Rigid Boxes China Wholesale • Wholesale Cannabis Concentrate Magnetic Lid Packaging Boxes • Foldable Magnetic Cap Baseball Hat Gift Box Packaging Vendor

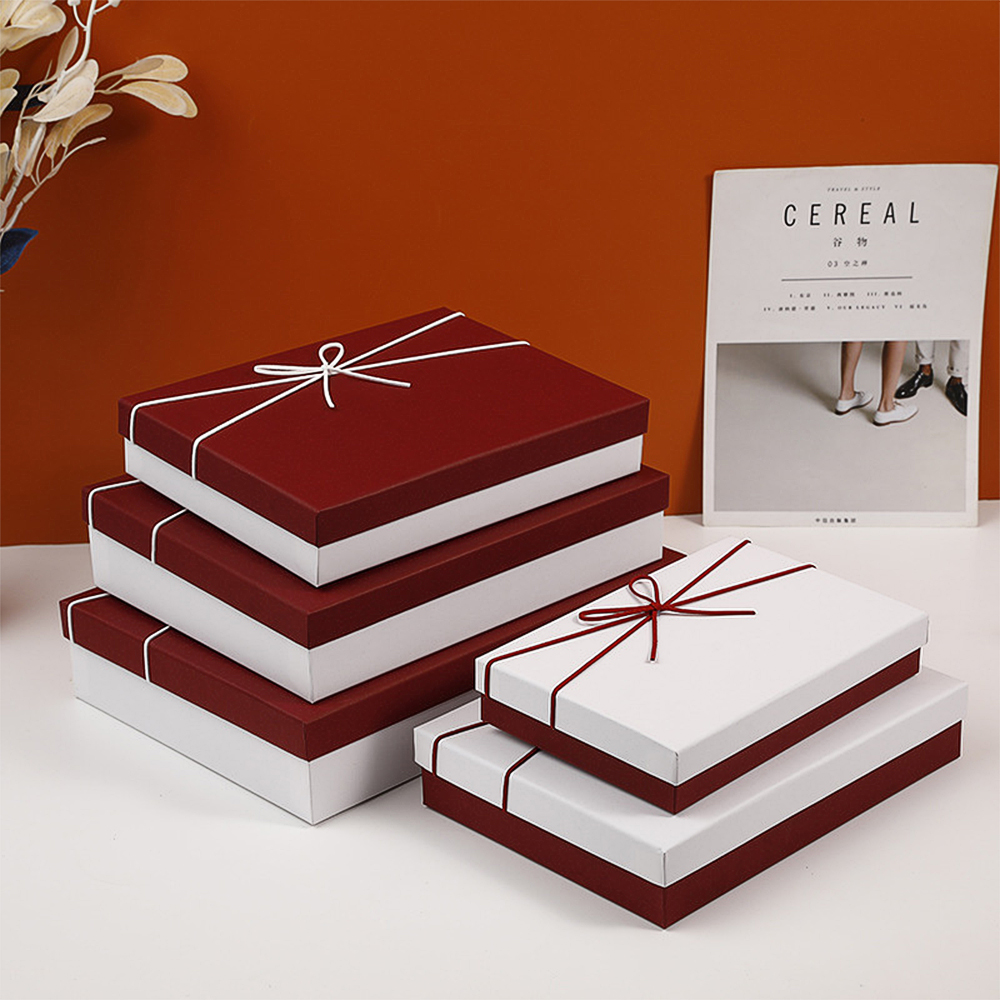

Magnetic Closure Boxes OEM: recycled materials that still look luxury

Magnetic lids sell the “unbox moment.” The trick is doing it with recycled content and clean printing. Use high-recycled greyboard for the core, then a premium printed wrap. Keep embellishment smart, not heavy. You’ll get that crisp snap-shut feel, but your fiber can re-enter the paper stream easier.

Recycled greyboard (chipboard) specs that don’t sag

- Core board: 100% recycled greyboard with stable caliper (e.g., 1.5–2.5 mm depending on size).

- Wrap paper: ≥30% recycled white or kraft. FSC Recycled or FSC Mix is preferred.

- Strength: luxury stiffness comes more from structure than virgin pulp. Don’t overbuild; it adds freight and doesn’t help retail.

Water-based print system (ditch the plastic gloss)

Skip full-sheet plastic lamination when you can. Water-based varnish or AQ coating keeps re-pulpability higher and cuts smells in closed boxes. CMYK + optional PMS spot, low-VOC inks. Foil? Use it small and smart—badges, thin lines, not large panels.

Removeable magnets and “design for disassembly”

Magnets are a love-hate part. Customers adore the snap; recyclers don’t. Solution: design magnets as easy-out parts. A micro-notch under the lining, or a pull-tab sticker behind the magnet cavity, lets users pop them out before recycling. Add a tiny icon and one-line instruction. It’s two seconds, saves a bin problem.

No-mag alternatives (when policy says “no metal”)

Ribbons, paper tabs, slit-lock tongues, or paper clasps deliver ritual without metal. For beauty kits or hemp sets, a ribbon tie looks elegant and passes most mixed-paper rules. Check these for ideas and finishes that still read premium:

- Custom Hemp Oil Magnetic Closure Rigid Boxes China Wholesale

- Wholesale Cannabis Concentrate Magnetic Lid Packaging Boxes

Collapsible magnetic rigid boxes: ship flat, breathe easy

If your warehouse is crying for space, go collapsible. The structure folds flat for transit and pops to shape with pre-applied double-sided tapes. That’s less pallet count, fewer dents, easier kitting. It’s green not only in material, but in logistics reality.

- Great fit for hats, kits, and seasonal bundles: Foldable Magnetic Cap Baseball Hat Gift Box Packaging Vendor

Table: quick spec guide for Sustainable Magnetic Closure Boxes OEM

| Item | Recommended Choice | Why it matters | OEM notes |

|---|---|---|---|

| Core board | 100% recycled greyboard, 1.5–2.5 mm | Stiffness with recycled content | Target FSC Recycled or Mix; stable GSM |

| Wrap paper | ≥30% recycled art paper/kraft | Premium printability + fiber recovery | Matte texture boosts perceived quality |

| Coating | Water-based varnish (AQ) | Better re-pulpability vs film lamination | If gloss needed, use light AQ gloss |

| Inks | Water-based/soy, CMYK + PMS | Lower odor, lower VOCs | Avoid heavy metallic floods |

| Closure | Removable magnets / ribbon lock | Easier recycling; policy friendly | Add “remove magnet before recycling” icon |

| Adhesive | Easy-repulp glue | Less stickies in paper mills | Control bead; avoid edge squeeze-out |

| Structure | Collapsible rigid (optional) | Flat shipping, lower damage | Pre-tape corners; quick set on line |

| Inserts | Molded paper pulp / recycled EPE (as needed) | Product safety + material story | EVA only when necessary; print recycling note |

| Compliance | FSC, clear recycling claim | Avoid greenwashing issues | Don’t claim recyclability if full-sheet film used |

Real-world use cases (talking your operations language)

Beauty & fragrance gift sets

You want luxe + clean shelf presence. Use soft-touch uncoated wrap with AQ matte (not plastic velvet). Add a thin foil crest only. A paper pulp insert cradles bottles. MOQ tight? We batch color ways on one diecut and use variable sleeves for SKUs. That’s how you keep line changeovers chill.

Hemp & concentrate kits

Regulatory teams ask for sturdy, tidy presentation. Recycled greyboard + kraft wrap reads honest. If you must use a magnet, do the removable type and print the recycle cue inside flap. Foam? Swap some SKUs to molded pulp. It’s cheaper to pack and less smell in long storage. See your niche pages for form factors and finishing cues above.

Electronics and home care gadgets

For devices like water flossers or small tools, go collapsible rigid to slash warehousing pain. Keep inserts hybrid: top paper pulp tray + bottom E-flute cradle. Add QR for quick start instead of extra leaflets. ISTA-style drop test on master carton is must; you don’t want returns spike, trust me.

Printing & finishing that stay recyclable

- Typography first. Big type, less solid floods. Cleaner for mills, cleaner for brand.

- Texture > plastic. Uncoated or linen-like paper gives hand-feel without film.

- Selective foil. Thin strokes, micro-badges. Large panels aren’t your friend.

- Color management. CMYK base + 1 PMS for logo control. Keep supply chain sane.

- Odor control. Water-based inks + AQ reduce “ink room” smell in closed packs.

Compliance and claims (keep it honest)

Say what the pack is, not what it isn’t. If you used plastic lamination, don’t call the outer wrap “widely recyclable.” If magnets are removable, show the tiny icon and one-step instruction. FSC marks require correct Chain-of-Custody and label code. Keep your spec sheet and print proofs on file; buyers will ask.

OEM workflow that saves you rework

- Design-for-disassembly. Magnet cavity with pull-tab, simple instruction.

- Spec lock. Board caliper, wrap GSM, coating type, insert material. No guess.

- Color proof. CMYK + PMS drawdown, AQ finish chip. Sign together.

- Die-line & kitting. One master die, sleeves for variants. This trims capex.

- Pilot run. 50–200 pcs for line test; check fold-flat assembly time.

- QC & transit. AQL sampling, corner compression, basic drop.

- Pack-out. Pallet map, stack height, no crush. Freight guys will thank you.

Pricing levers (without giving numbers)

- Collapsible saves on inbound warehousing and outbound damages.

- Recycled boards are cost-steady and easier to source at volume.

- Cutting film lamination reduces process steps. Less cycle time, less defects.

- Variable sleeves + shared inners let you scale SKUs without new tooling each time.

Why China Custom Boxes Factory (and a word on LOVINHUG)

You need stable MOQ, real lead time, and a team that speaks both brand and factory. We run rigid boxes, folding cartons, paper tubes, gift bags—so kitting multi-format sets is smooth. For lifestyle labels like LOVINHUG, that mix—magnetic rigid + sleeve + mailer—lands consistent. No fancy talk, just repeatable quality.

Magnetic Closure Boxes is your starting hub. If you’re scouting sector-specific shapes or inserts, browse the hemp and concentrate pages linked above, or the fold-flat hat box for structure ideas.

FAQs in one breath (a bit messy but helpful)

Do magnets mess up recycling? Yes if you don’t remove them. Can we keep the “click” feel? Sure, removable magnets or ribbon locks. Film gloss? Try AQ gloss first. Foam? Use paper pulp where possible. MOQ? Talk to us; small pilots ok. It’s not rocket science, just need right spec and honest claims.

Keyword-titled argument blocks you can lift into sales decks

Recycled Greyboard Magnetic Closure Boxes

Short: recycled core gives stiffness with lower footprint. Make sure caliper matches product mass.

Water-Based Inks and AQ Coating for Rigid Boxes

Short: better odor profile, better mill behavior, and still crisp color. Good for cosmetics and food-adjacent.

Removable Magnet Design for Recyclability

Short: micro-notch or pull-tab. Print a tiny icon “remove magnet before recycling”.

Collapsible Magnetic Rigid Boxes for Flat Shipping

Short: ship flat, assemble fast. Lower damage, cleaner pallets, happier 3PL.

FSC Recycled / FSC Mix for Packaging Claims

Short: use correct label and CoC. No over-claim. Buyers trust consistency more.

Mini data table: ops wins you can tell your team

| KPI | What changes | Why buyers care |

|---|---|---|

| Warehouse density | Collapsible structure packs flat | Fewer pallets, easier slotting |

| Return rate | Better corner build + pulp inserts | Less transit scuff and break |

| Claim risk | Honest recyclability + FSC | Retail compliance, less headache |

| Line speed | One die + variable sleeves | Faster changeover, fewer errors |